Method and system for temperature control in refrigerated storage spaces

a technology for refrigerated storage space and temperature control, which is applied in the direction of compression machines with non-reversible cycles, applications, lighting and heating apparatus, etc., can solve the problems of substantial energy consumption in today's refrigerated storage space, achieve the effect of avoiding energy-inefficient part-load operation, maximizing cooling energy efficiency of the cooling unit, and improving production quality preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

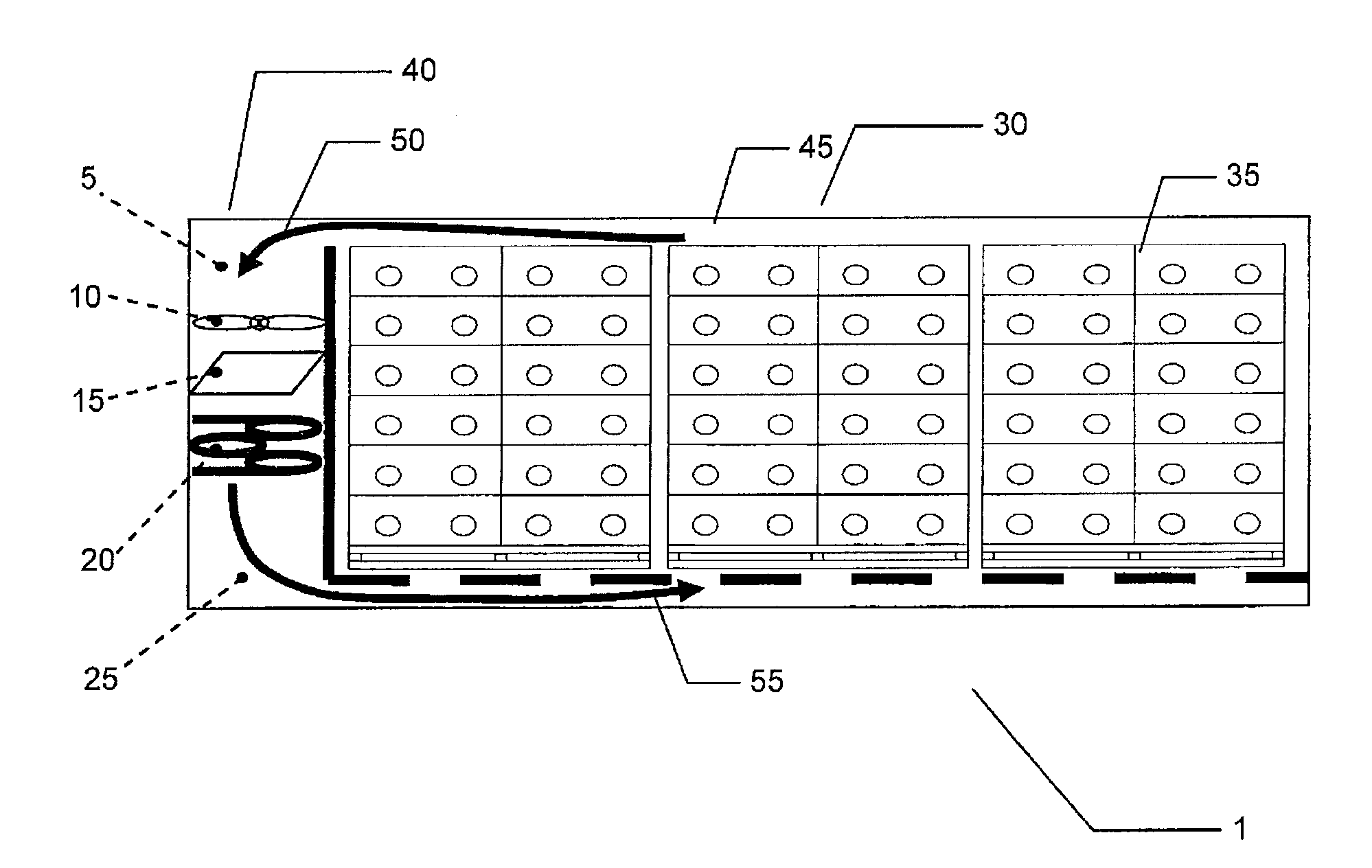

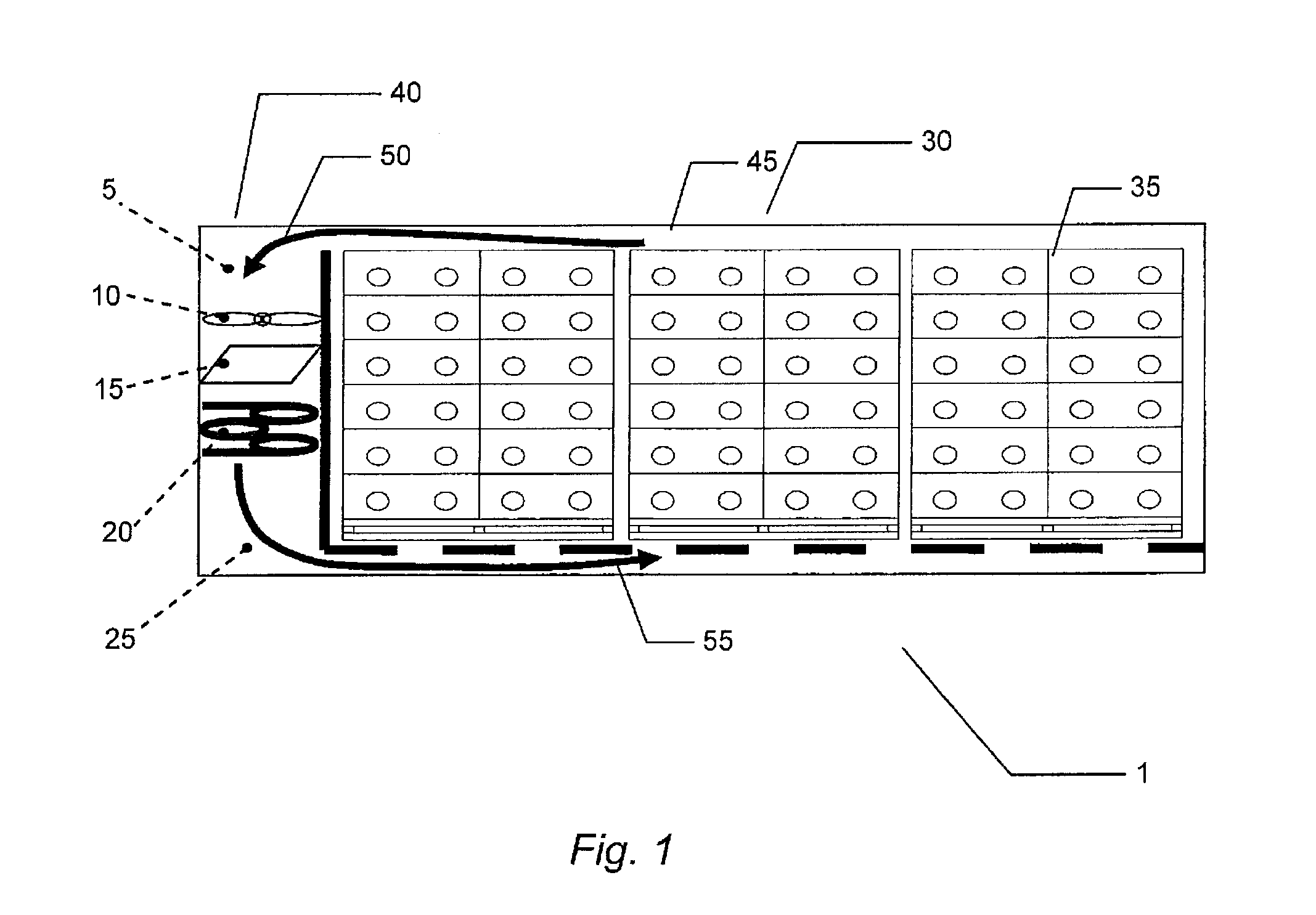

[0072]In FIG. 1, the refrigerated container 1 comprises a frontal section having a refrigeration unit 40 housing multiple, usually two or three, variable speed internal fans 10 (depicted schematically as a single fan), heating unit or element 20 and a cooling unit 15. A load or cargo section 30 of the refrigerated container 1 comprises a commodity load comprising a plurality of stackable transport boxes 35 arranged within a transport volume 45 such as to leave appropriate clearance at a ceiling and a floor structure for air flow passages above and beneath the commodity load. The frontal section comprises a refrigeration unit 40 comprising return air temperature sensor 5 adapted to measure a temperature of a return air flow 50 comprising air that has been circulated through the transport volume 45. Another temperature sensor 25 is adapted to measuring a supply air temperature of heated or cooled supply air 55 discharged into the transport volume 45 through an air flow passage. A temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com