Steam Pressing Iron With Automatic Condensate Removal

a technology of steam pressing iron and condensate removal, which is applied in the field of steam pressing iron with automatic condensate removal, can solve the problems of staining of fabrics being ironed,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Conventional Iron

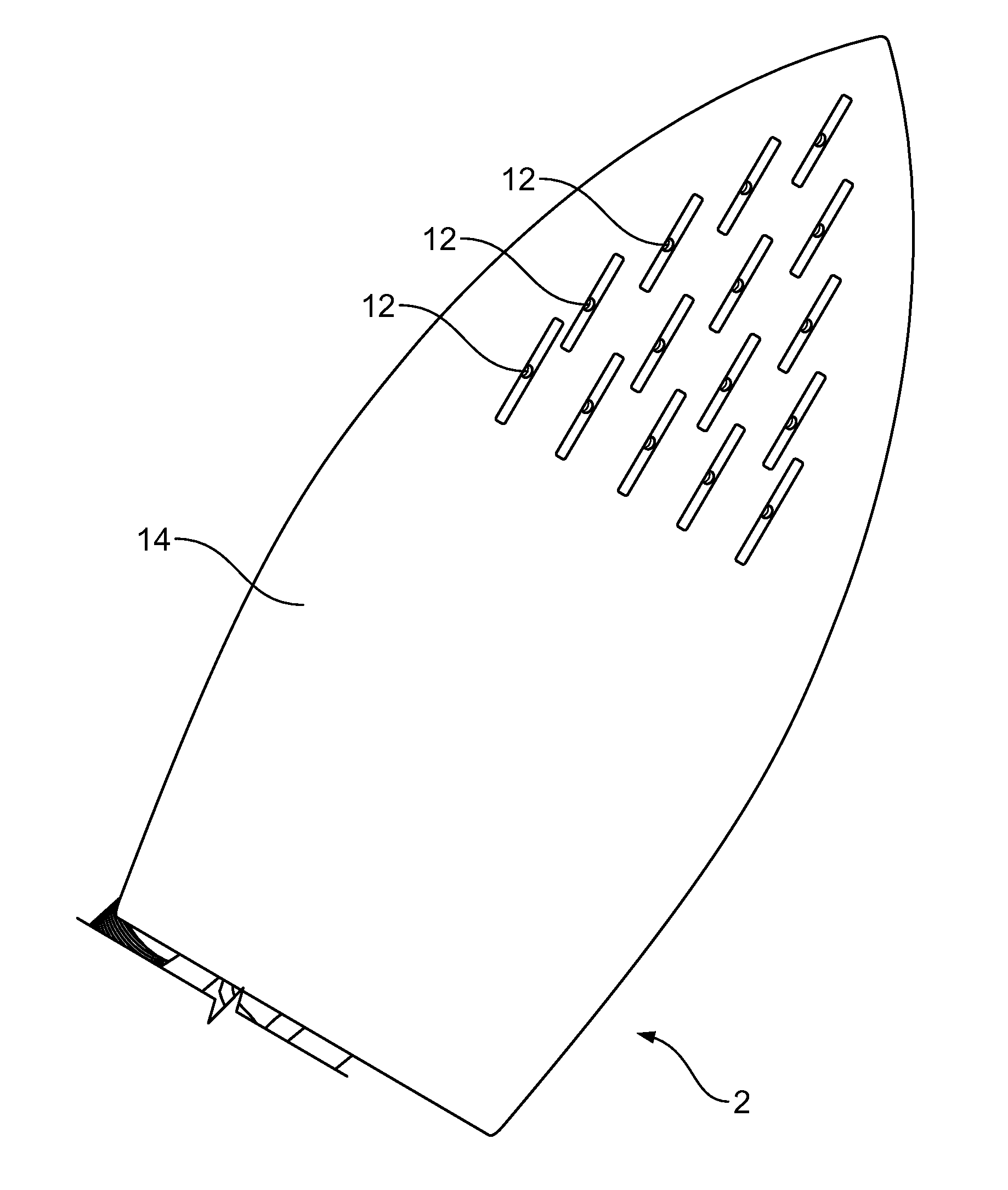

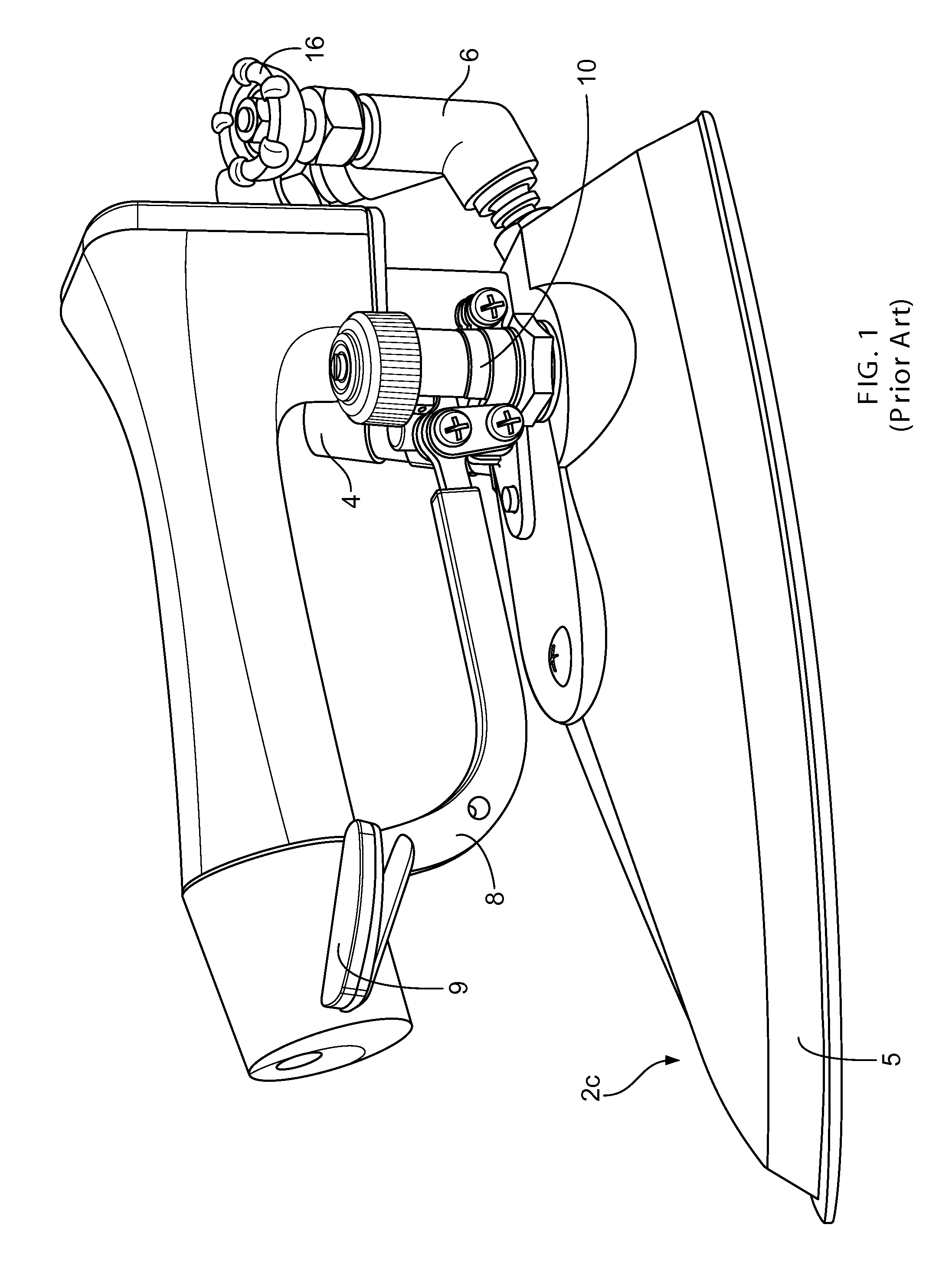

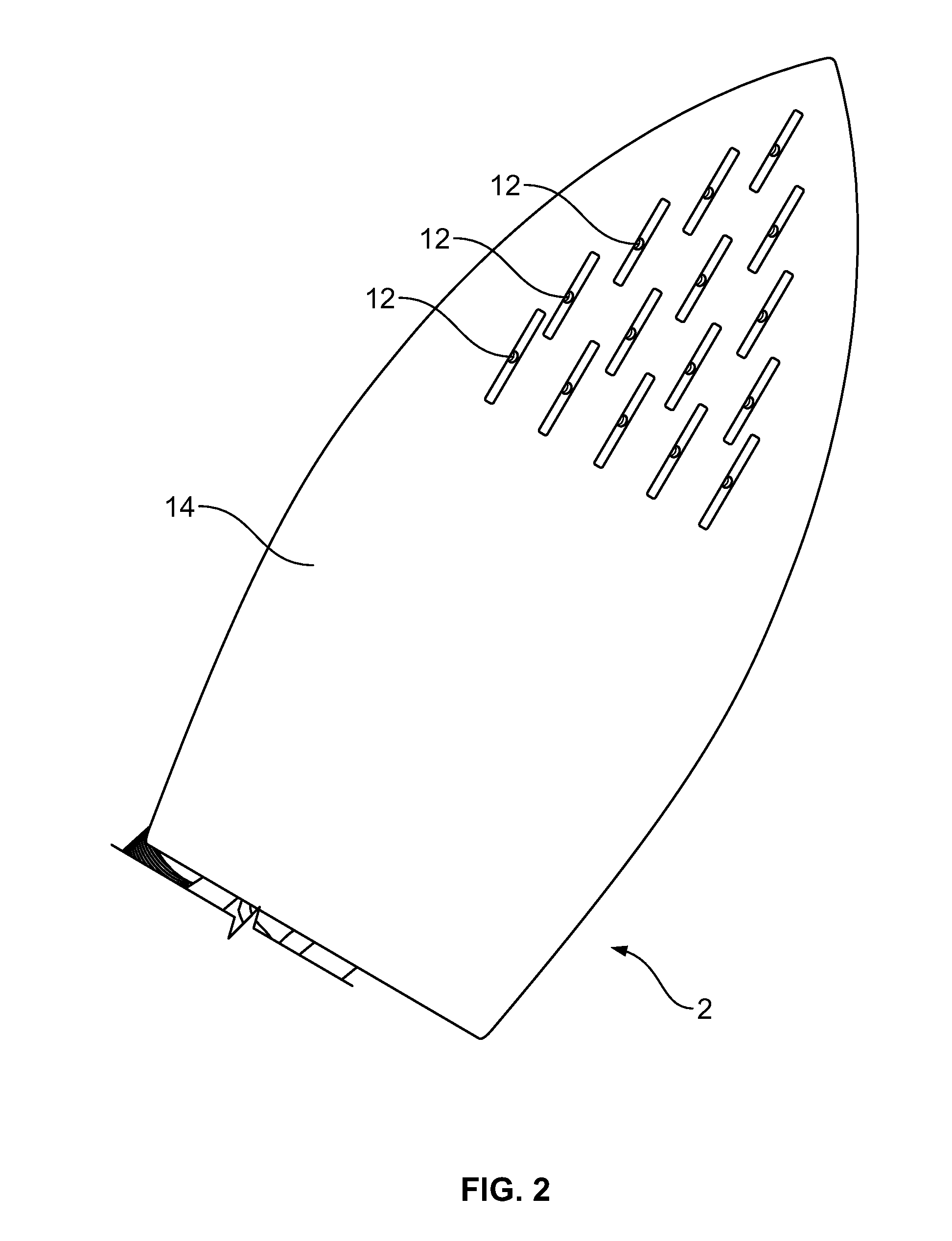

[0015]FIG. 1 shows a conventional steam powered iron 2c.

[0016]Steam is supplied by a boiler through a steam hose, to a steam connection 4. Steam collects in a steam chamber inside body 5, and heats the iron 2c. Lever 8 is depressed by thumbpad 9 to actuate steam discharge valve 10. This discharges the steam, under its steam pressure through a plenum to a plurality of vents 12 (FIG. 2) in bottom 14 of the iron, applying steam to the garment being pressed. As long as the steam is liberally discharged, the iron 2c remains hot and full of steam. But if the iron 2c sits idle for a while, heat is lost to the atmosphere, and the steam, giving up its heat of vaporization, condenses.

[0017]It is not desirable to wet the garment with liquid water, when the steam is discharged. So the condensate should be purged. Manual turn valve 16 is therefore opened by the operator, to discharge the condensate through a condensate connector through a second hose, a condensate return hose, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| steam pressure | aaaaa | aaaaa |

| horizontal twisting forces | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com