Vapour and water separator

A technology of steam-water separator and separation cylinder, which is applied in the direction of separation method, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of low critical flow velocity of steam-water separator, and achieve the improvement of critical inlet steam flow velocity, uniform steam distribution, and drainage good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

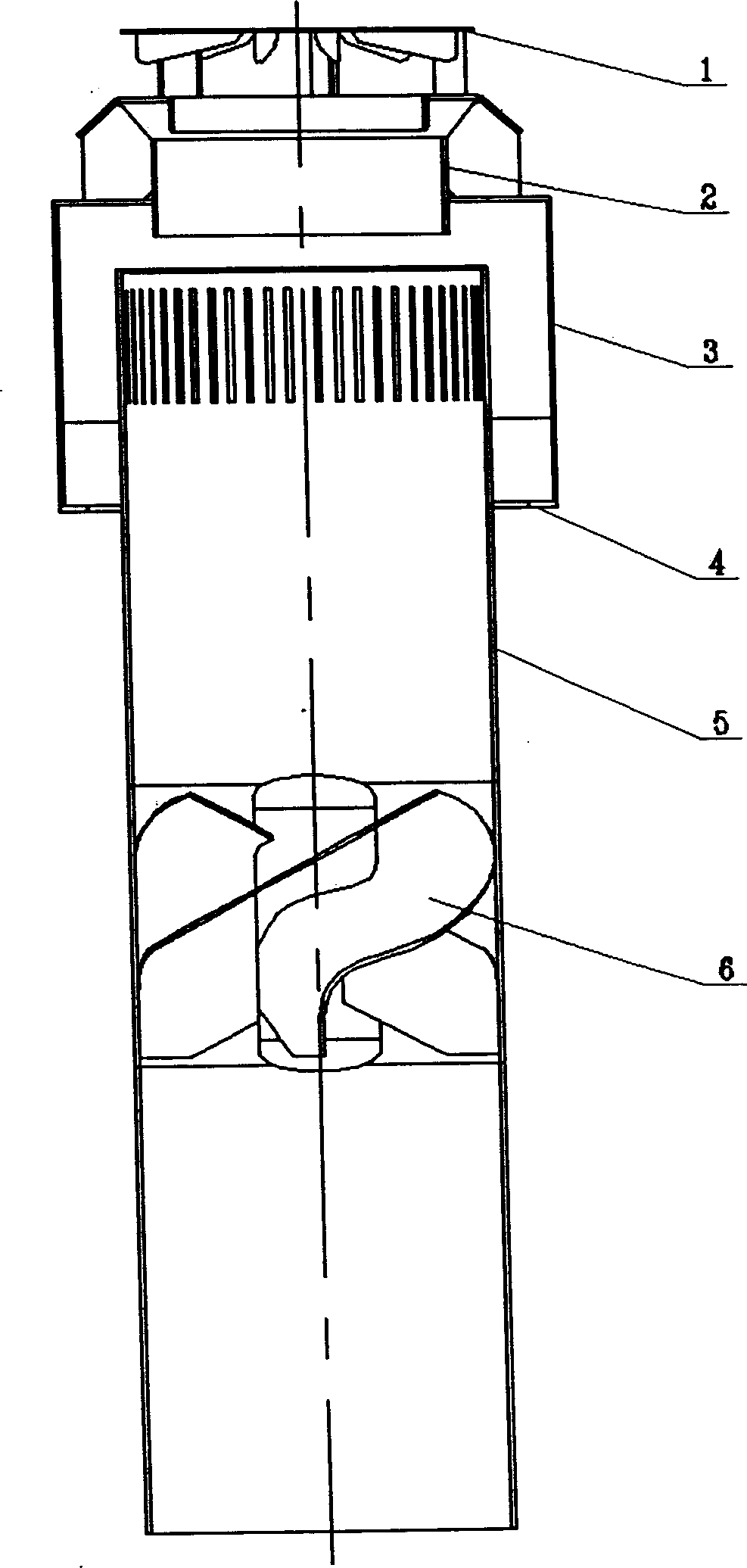

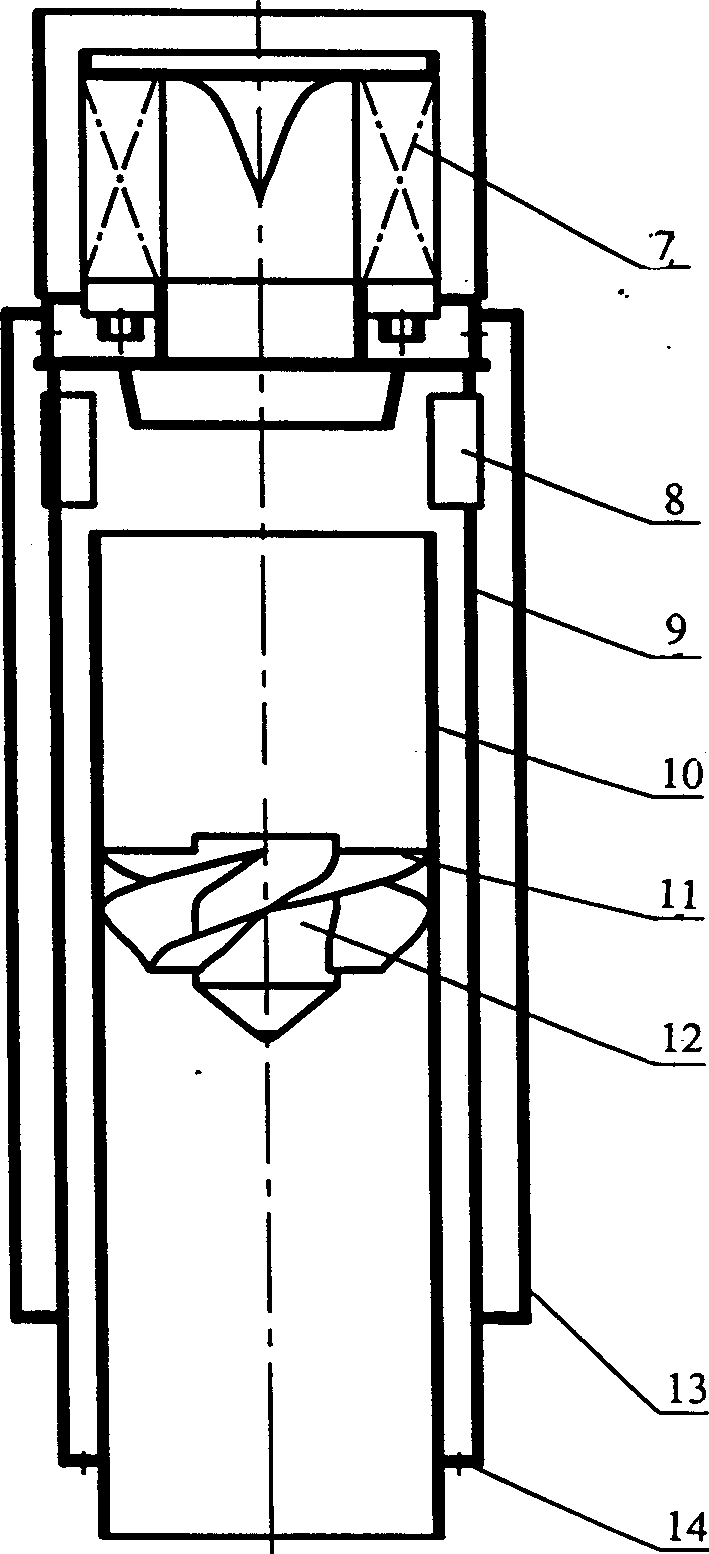

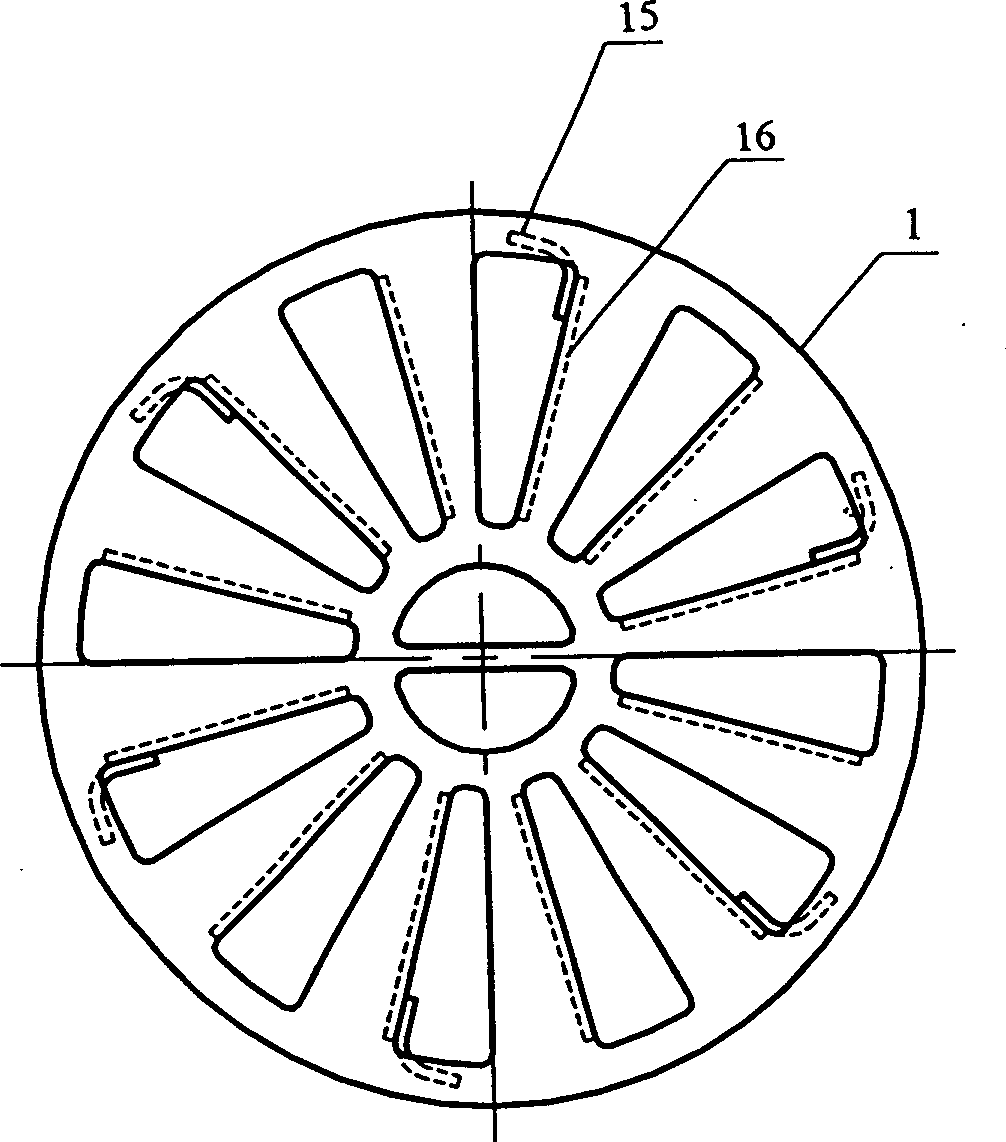

[0018] Such as figure 1 As shown, the steam-water separator includes a separation cylinder 5 and a sleeve 3 sleeved outside the separation cylinder 5. The lower part of the sleeve 3 is provided with a hydrophobic restrictor ring 4, and the central column in the separation cylinder 5 is provided with double inclined blades 6. The entire steam generator is filled with water below the center of the double inclined blades. The length of the sleeve 3 of the present invention is relatively short, and the entire sleeve 3 including the hydrophobic restrictor ring 4 is located above the water space, so that bypass steam can be avoided. Entering the descending passage of the steam generator, eliminating the downcarrying phenomenon of the general steam-water separator, the bottom of the sleeve 3 is welded with the hydrophobic flow-limiting ring 4, which can limit the flow rate of water and prevent the steam from flowing out. The top of the separation cylinder 5 is provided with a steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com