Full-intelligent dynamic yaw control system

An intelligent dynamic, yaw control technology, applied in the control of wind turbines, engines, wind power generation, etc., can solve the problems of single function and poor effect, and achieve the goal of improving accuracy, good control effect, and reducing yaw load. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing this embodiment is described in detail

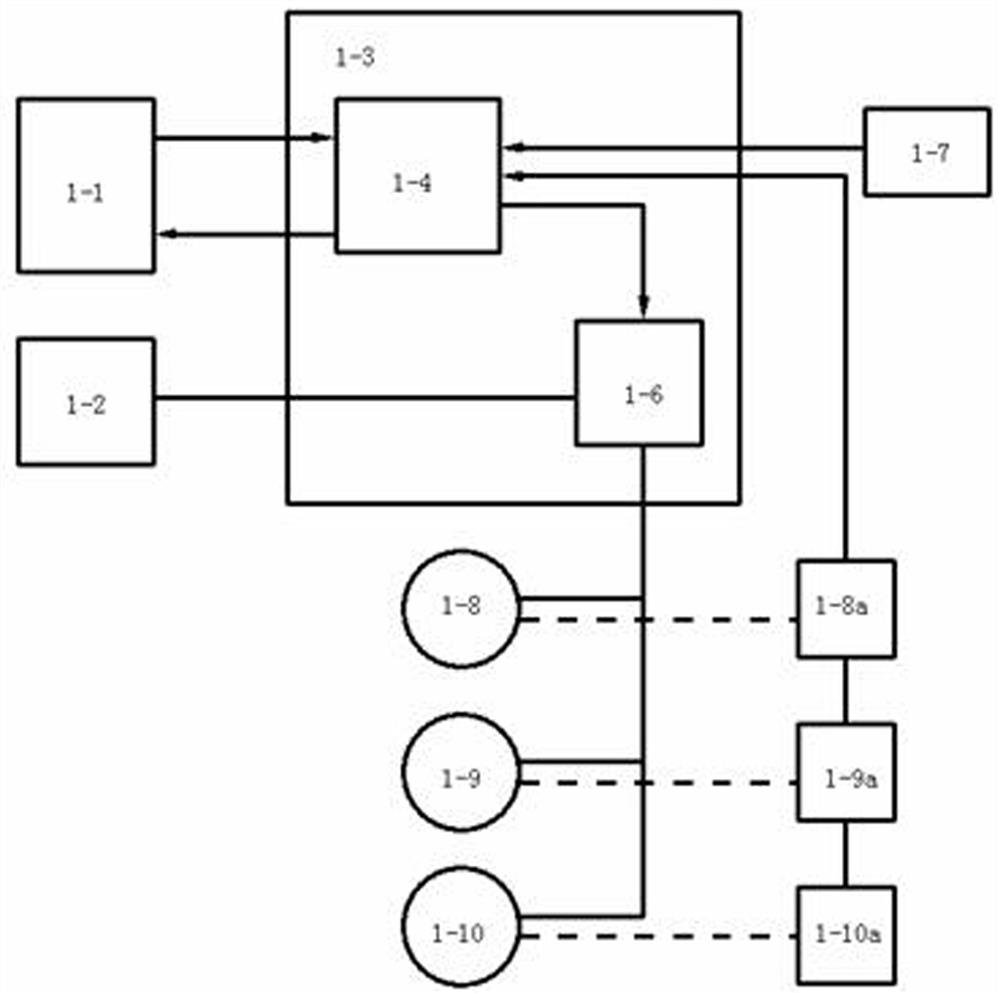

[0011] Depend on figure 1 It can be seen that the present invention adopts centralized management and decentralized control mode, which is centrally managed by the main control system PLC and controlled by the built-in PLC of the frequency converter. The frequency converter adopts a frequency converter with a built-in PLC module inside, which can save the cost of purchasing PLC separately.

[0012] The yaw motor drive method adopts one inverter with multiple yaw motors to save installation space. The yaw motors are connected in parallel, and the protection devices of the yaw motors are connected in series to ensure that all motors are not allowed to run after the protection device of any motor on the load is triggered, so as to avoid greater losses.

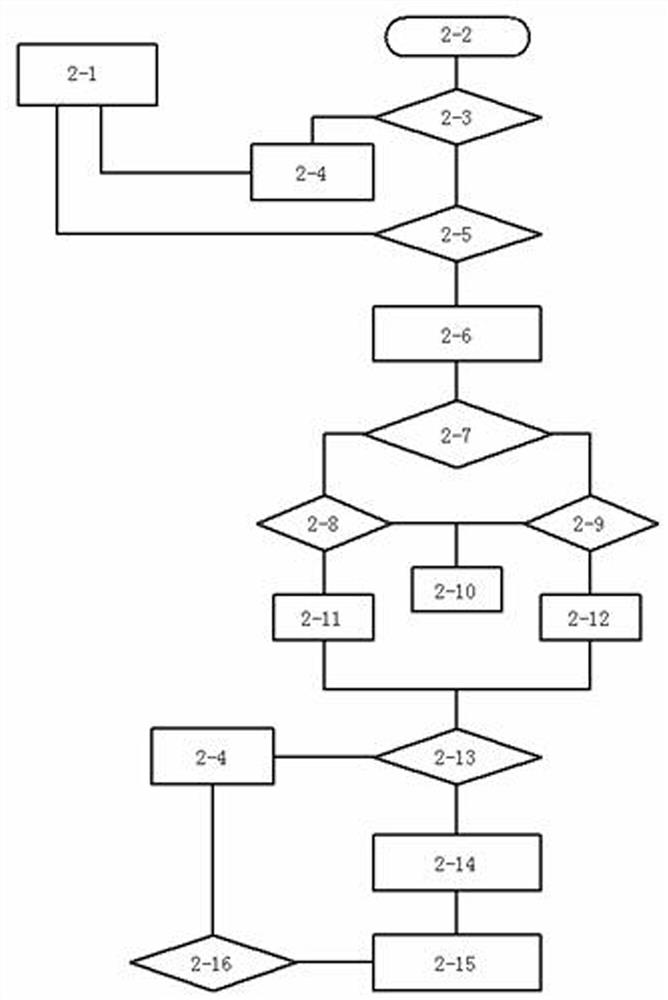

[0013] Three control modes: remote mode, local automatic mode, local manual mode. In the remote mode, the frequency converter (1-3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com