Drawer

a technology for drawers and back walls, applied in drawers, furniture parts, domestic applications, etc., can solve the problems of reduced force transmission via back walls, increased production costs per back wall, and complex corner joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

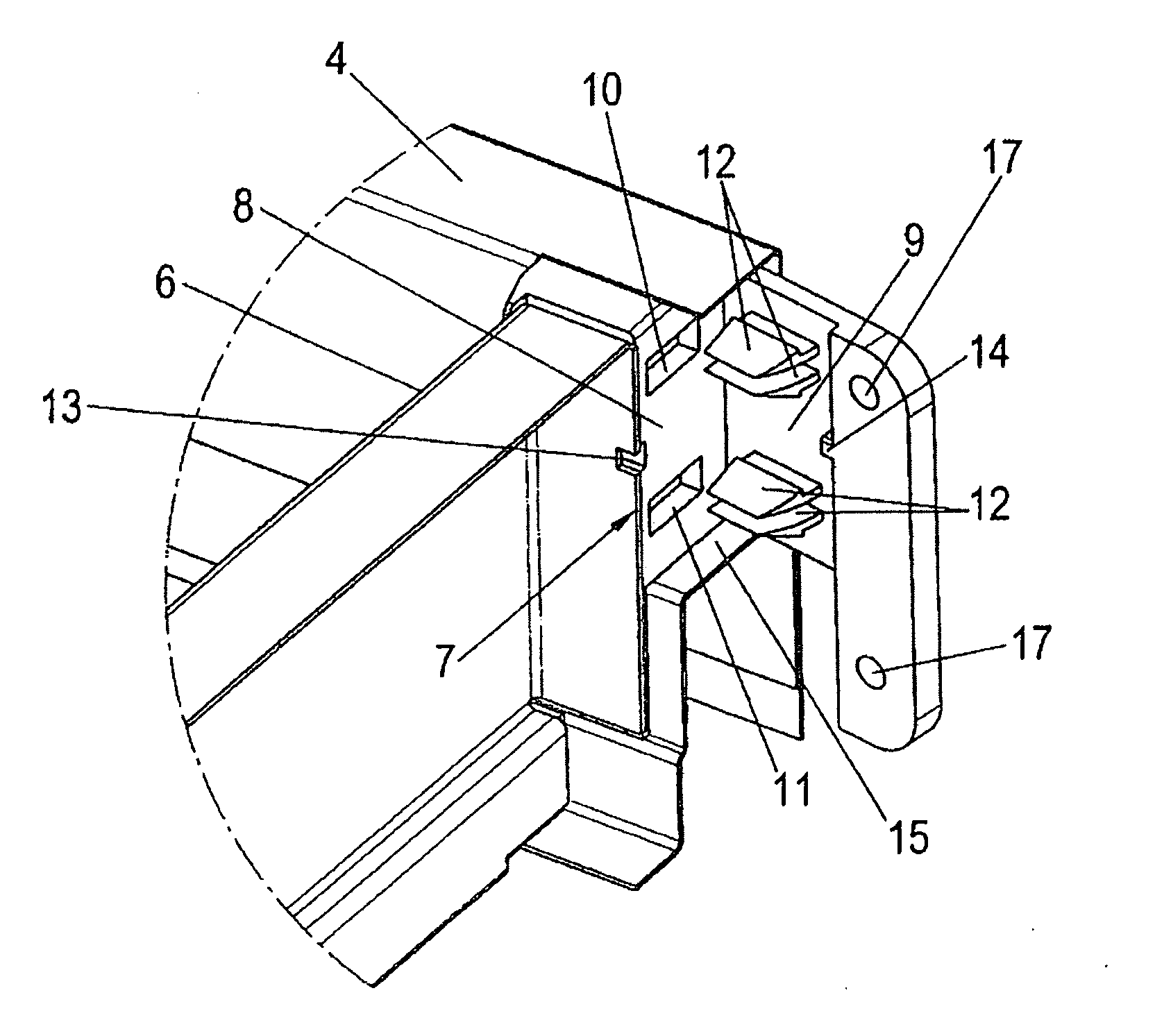

[0029]The drawer 1, shown in FIG. 1, includes a bottom part 2, a front panel 3, two lateral frames 4, 5 and a back wall 6. The back wall 6 is connected to the lateral frames 4, 5 by corner joints 7.

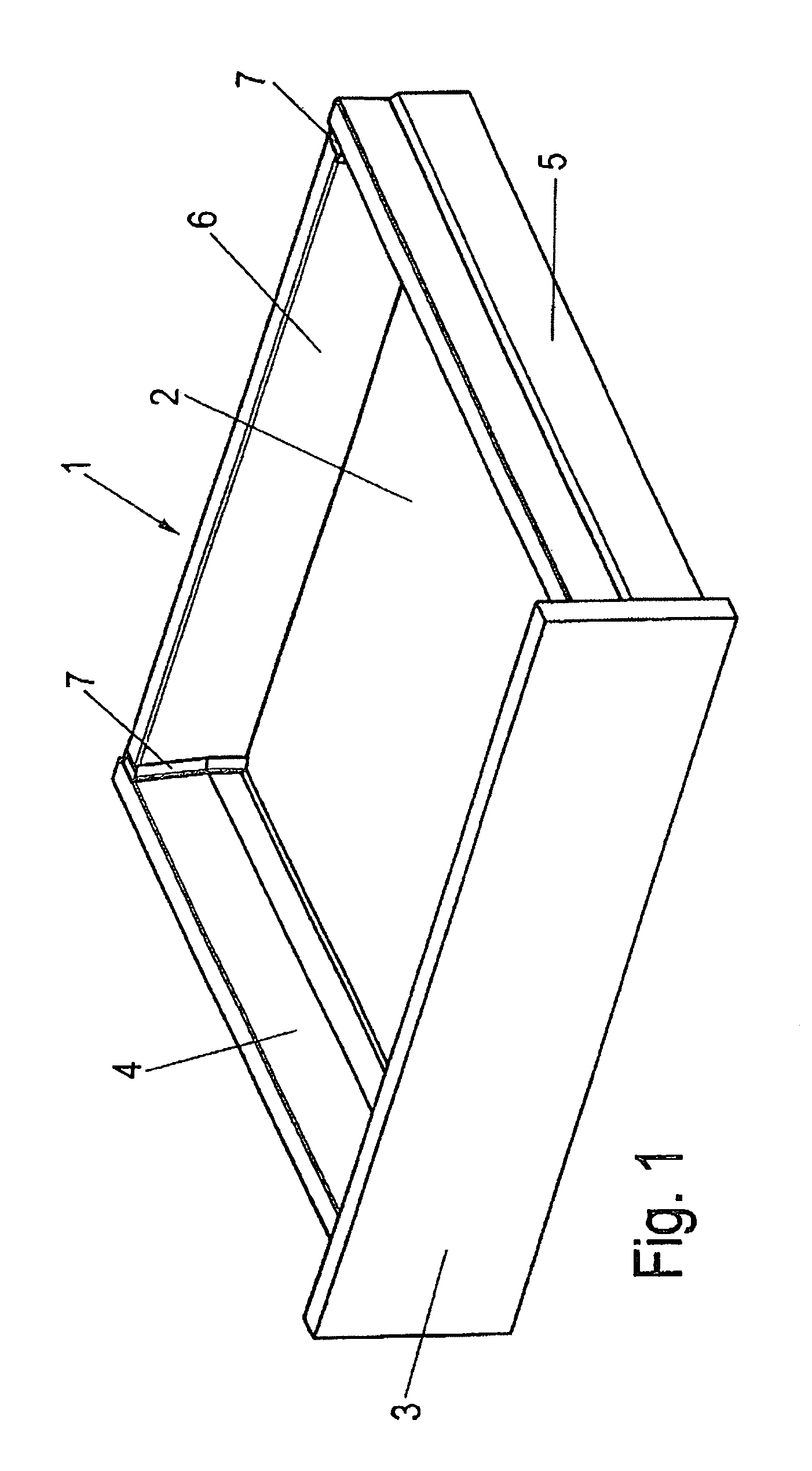

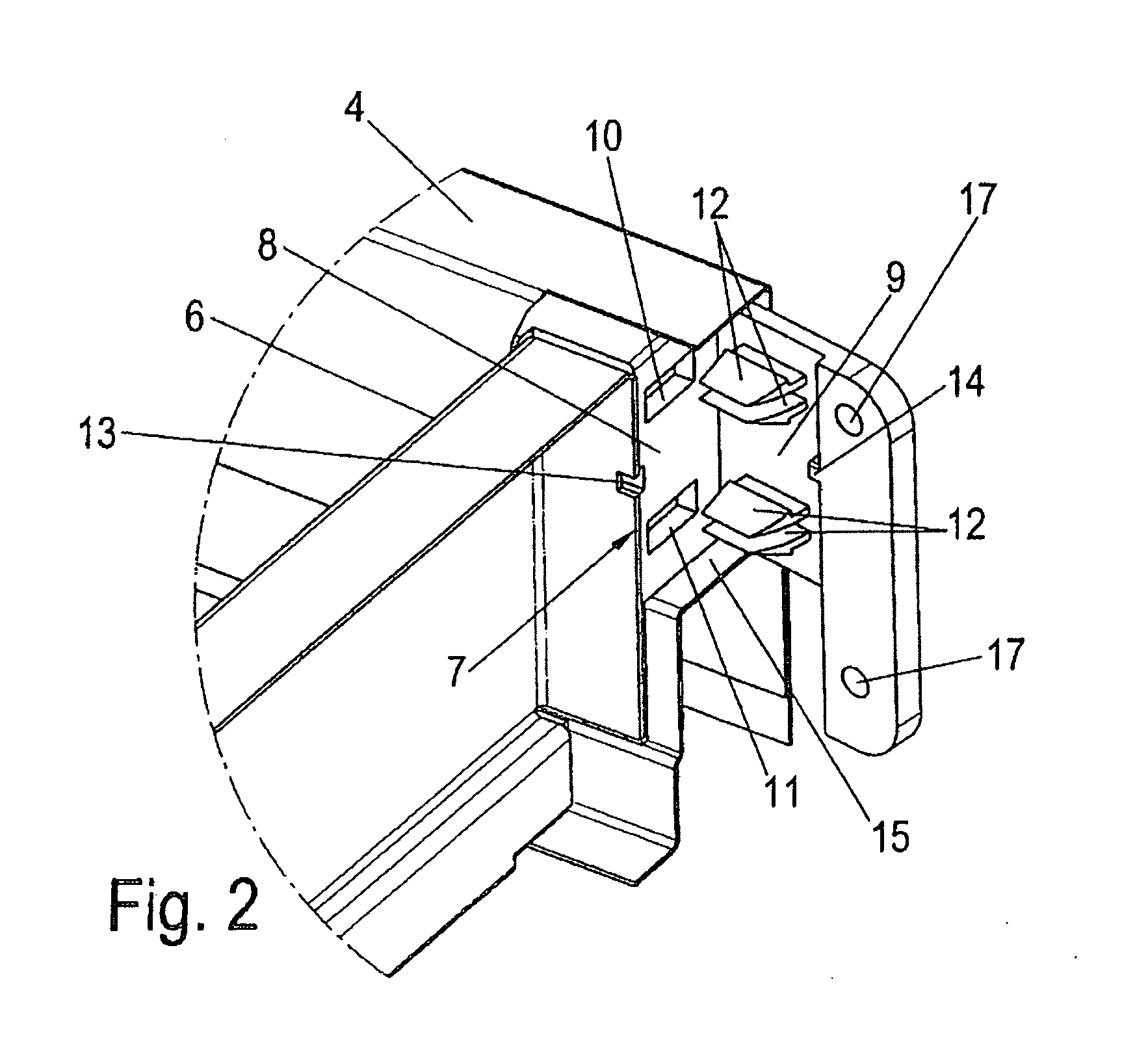

[0030]As is shown in FIGS. 2 to 6 and 8, each corner joint 7 includes a first connecting part 8 and a second connecting part 9, which parts 8, 9 are configured to be latched into one another. The two connecting parts 8, 9 are connected to one another in the manner as shown in FIGS. 6 and 8 by way of a film or living hinge 18 forming a vertical rotational axis as shown and suggested in FIGS. 2, 3 and 5. As is shown in FIGS. 5 and 6, the first connecting part 8 is arranged on a bottom side on an adapter 15 and is held by integrally arranged T-shaped pins 21 and knobs 22 acting as detent means, as shown in FIG. 8. The formation of associated recesses 19 in the adapter 15 is shown in FIG. 7. The corner joint 7 is inserted with T-shaped pins 21 in the keyhole-like recesses 19 and displaced the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com