Pyrotechnic actuator and method of actuating a pyrotechnic actuator

a technology of pyrotechnic actuators and actuators, which is applied in the direction of blasting cartridges, weapons, weapon components, etc., can solve the problems of equipment and/or personnel near such devices, devices that do not control the release of hot gases or flames, and are considered hazardous to use such devices in certain applications

Inactive Publication Date: 2012-09-20

SPECIAL DEVICES

View PDF5 Cites 62 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

[0004]It is an object of the invention to alleviate or remove entirely the hazards created by firing pyrotechnic actuators, particularly the hazards created by flames and / or exhaust gases escaping from the device after firing.

Problems solved by technology

However, in many applications the release of hot gases and / or flames during device functioning may create a safety hazard for equipment and / or personnel near such devices.

Devices that do not control the release of hot gases or flames are also considered hazardous by regulatory agencies in US and worldwide and require special packaging, storage and regulatory permits for transportation and the use of the product throughout the life of the product.

The requirements are stringent enough that they may prevent the use of such devices in certain applications especially some cost sensitive applications due to the additional costs involved.

It is not practical to make all such devices out of metals such as in this case of electrical power / battery disconnects or to have a tubular piston-cylinder with O-ring configuration.

Some applications require odd shapes for device configuration that are much more difficult to seal than simple O-ring type designs.

It is sometimes impossible or not practical to verify if the seal is in place and installed correctly once the device is closed.

For parts that are expected to be used over many years of service the useful life of gaskets, O-ring or sealant is also a limiting factor especially in harsh installation and operating environments.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

first embodiment

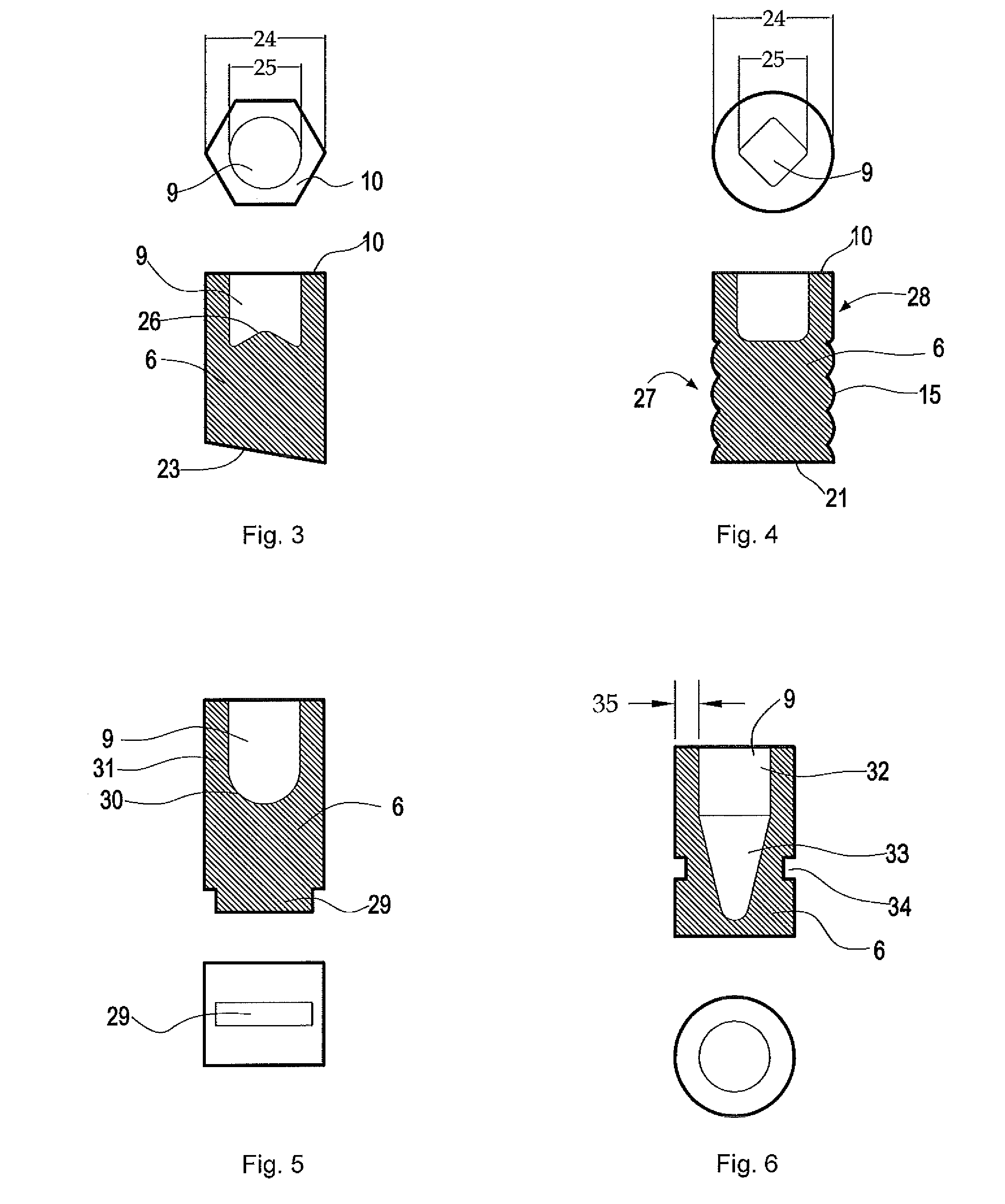

[0037]FIG. 3 shows a sectional view and a rear end view of a piston forming a part of the pyrotechnic actuator according to the present invention.

second embodiment

[0038]FIG. 4 shows a sectional view and a rear end view of a piston forming a part of the pyrotechnic actuator according to the present invention.

third embodiment

[0039]FIG. 5 shows a sectional view and a rear end view of a piston forming a part of the pyrotechnic actuator according to the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

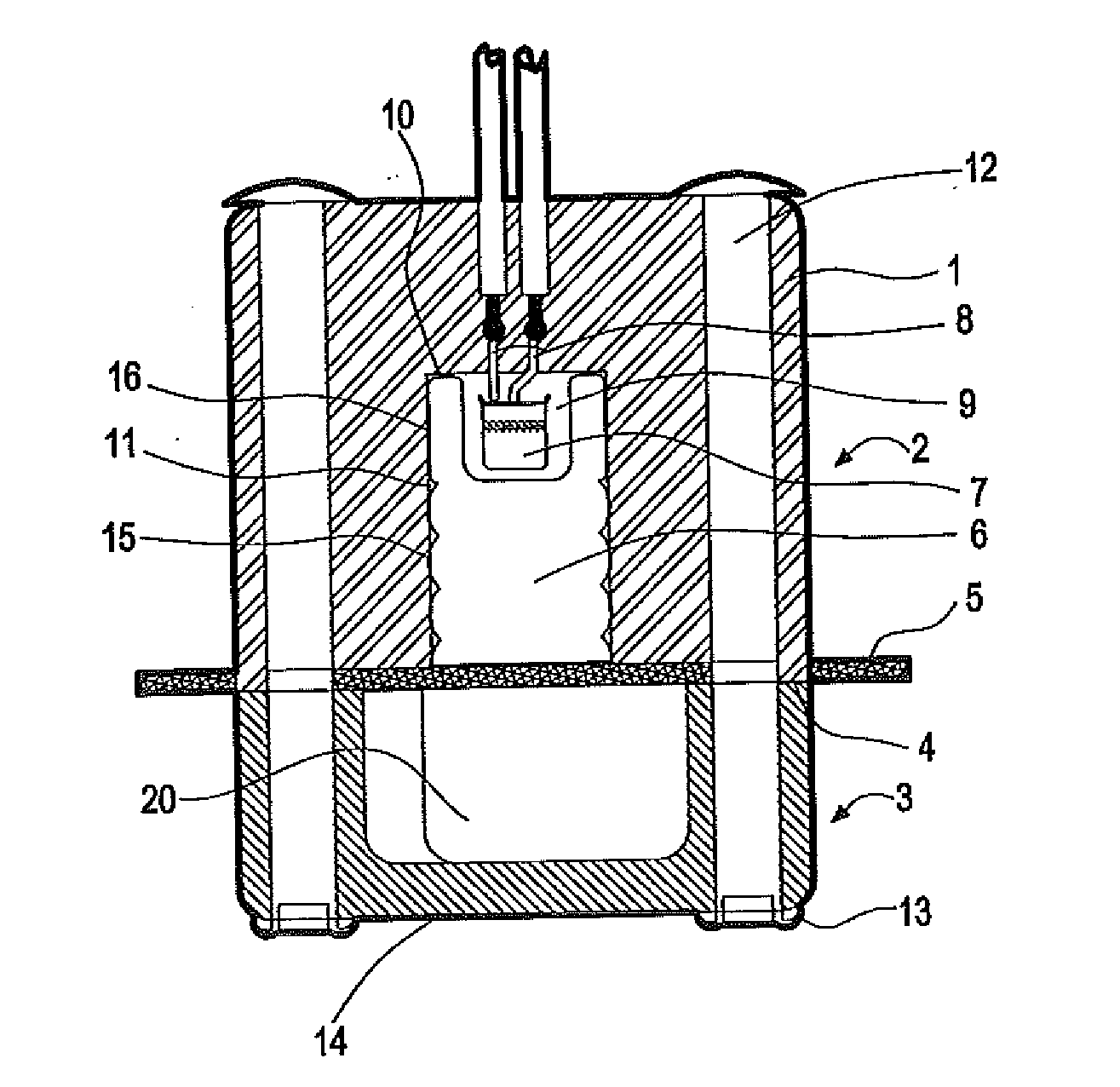

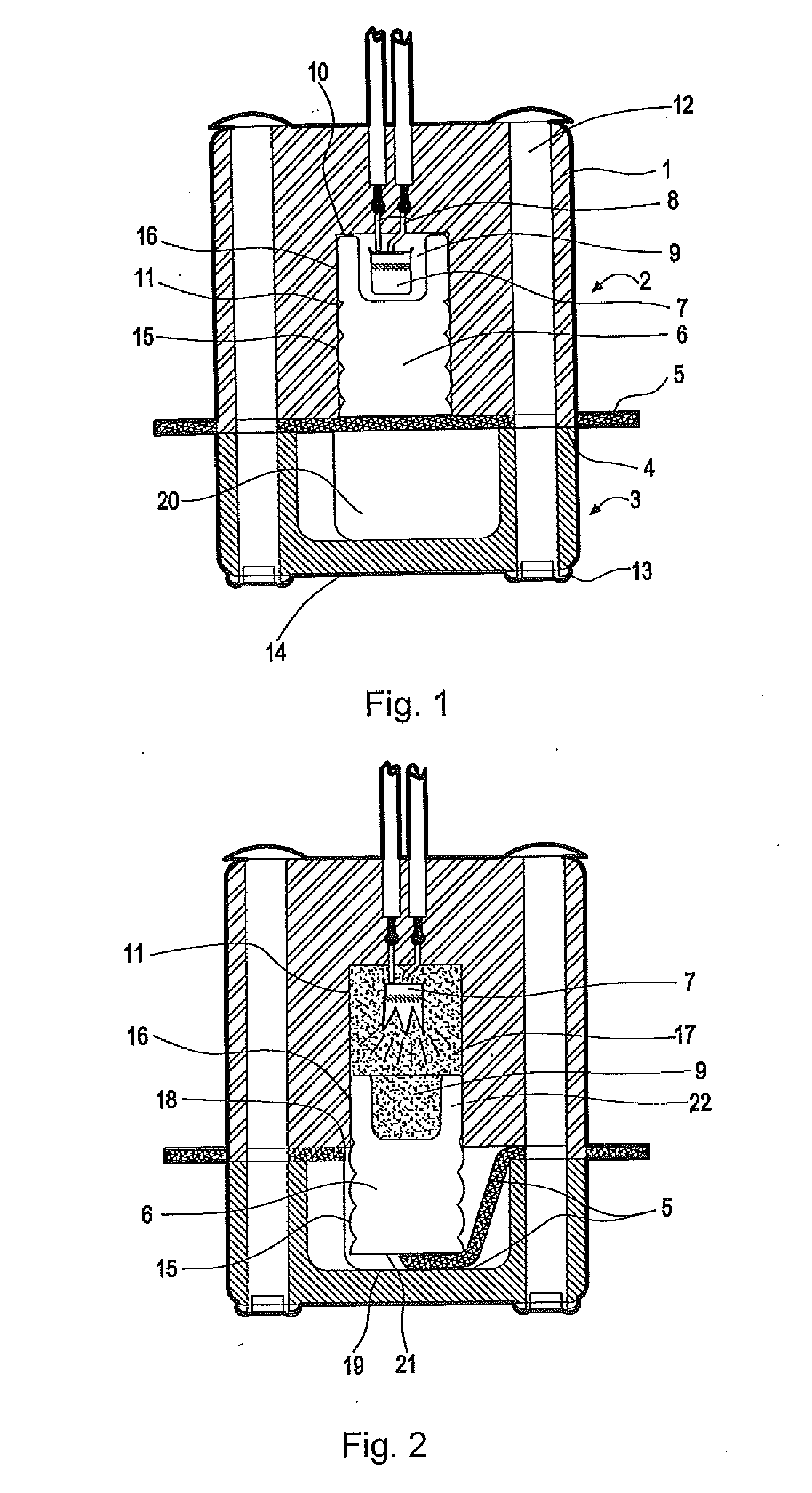

A pyrotechnic actuator and a method of actuating the same are described. The actuator comprises a pressure chamber and a piston having such an outer diameter that it is snugly fitted into the pressure chamber. A gas generating ignition and output charge generates gas that pressurizes the pressure chamber and the piston when ignited. The piston is designed such that at least part of its outer diameter expands under the pressure in the pressure chamber such that at least a part of the external piston surface is forced into a press fit against the internal wall of the pressure chamber and therefore seals the pressure chamber. This prevents exhaust gas and flames from escaping from the device in an uncontrolled manner.

Description

FIELD OF THE INVENTION[0001]The invention is in the field of controlling the release of primer / initiator exhaust gases and flames from pyrotechnic actuators to improve operational safety and to meet regulatory requirements. The invention is in particular in the field of pyrotechnic actuators such as pyrotechnic power disconnect devices, pyrotechnic battery disconnect devices, pyrotechnic fuses, pyrotechnic switches, pyrotechnic cable cutters, pyrotechnic release devices, pyrotechnic locking devices, and pyrotechnic interrupters.BACKGROUND OF THE INVENTION[0002]Pyrotechnics have been used in break, sever, disconnect or release devices and mechanisms for a long time. As an example, for instance applicant's U.S. Pat. Nos. 7,123,124 and 7,239,225 can be named, the content of which is herewith incorporated by reference. When some of these devices were actuated, the primer exhaust gases and / or flames were released to the surroundings. In some applications the release of hot gases, smoke a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F42B99/00

CPCF42B3/006

Inventor TIRMIZI, ABRAR A.

Owner SPECIAL DEVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com