Recyclable packaging container for dry based powders, grains, particulates and aggregates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

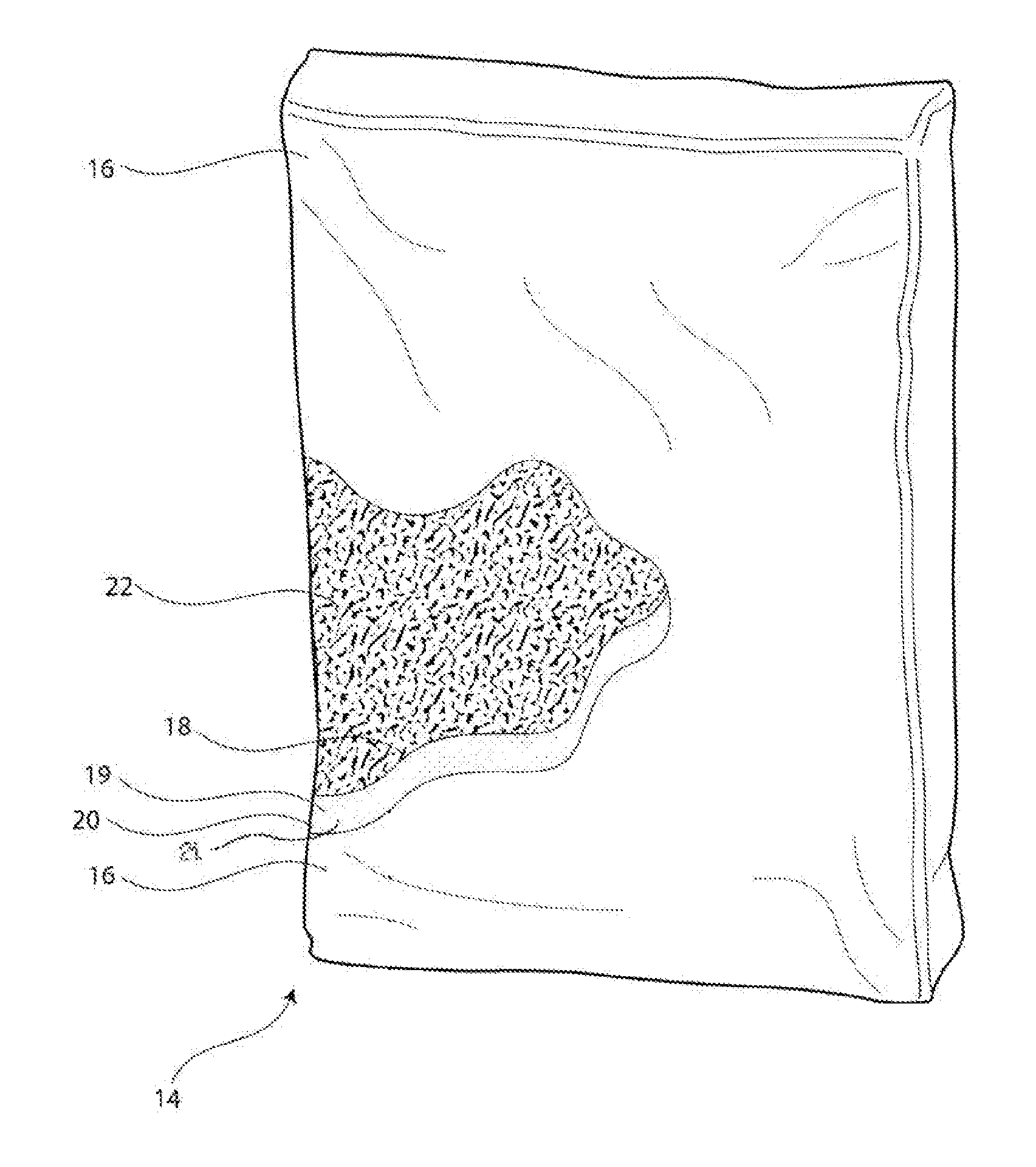

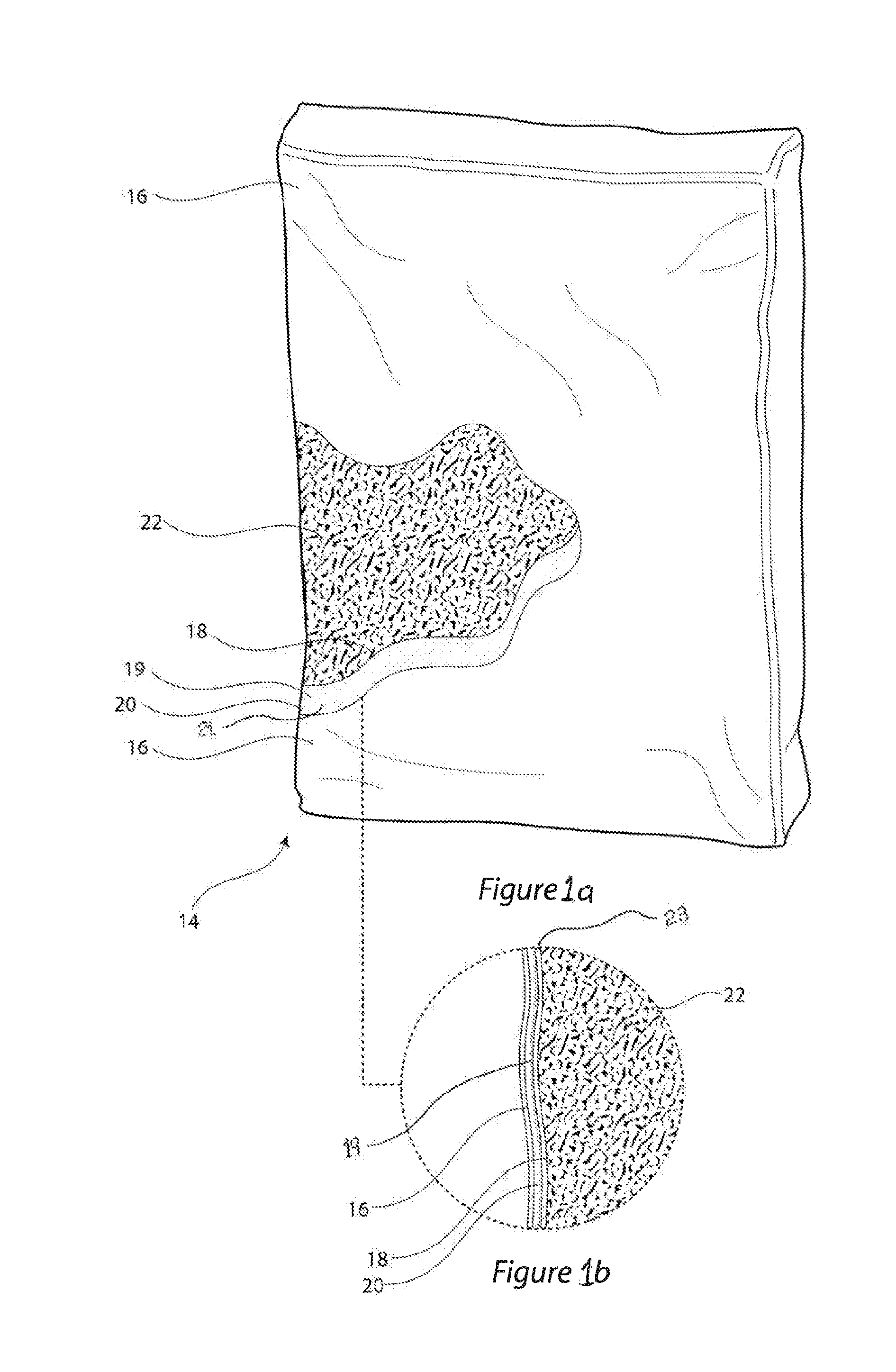

[0043]FIGS. 1A and 1B show a preferred embodiment of this invention wherein the recyclable packaging container is a bag (14).

[0044]The bag (14) includes an outer ply of high density porous paper (16) and an inner ply of high density porous paper (18).

[0045]On the external surface (23) of the inner ply of high density porous paper (18) the hydrophobic biodegradable material (20) has adhered to the external surface (23) as droplets (19).

[0046]In between these droplets (19) are a series of spacings (21).

[0047]While not shown in the illustrations, when the contents of the bag (22) were received during filling, as the contents (22) are for the most part dry powders, particulate material, aggregates of cement and so forth it is very much a fluid process in the bagging of such material.

[0048]Therefore the bag (14) must have a degree of aeration otherwise during the filling process of the contents (22) into the bag (14) the dust of the product being bagged becomes a significant hazard.

[0049...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com