Optimization of dead space in pistonless compressors

a dead space and compressor technology, applied in the direction of positive displacement liquid engines, pump control, non-positive displacement pumps, etc., can solve the problems of separator units, undesirable carrying along, and disadvantages described in context with common compressors, so as to increase the delivery rate of pistonless compressors and minimize specific compression energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]A separation of the liquid delivered in excess from the compressed medium is advantageous or required in particular when the liquid delivered in excess represents an undesired contamination in a subsequent process, to which the compressed medium is supplied. When ionic liquids are used as operating means, a separation and return of the liquid delivered in excess seems to be sensible for cost reasons as well. Furthermore, the “loss” of the liquid quantity delivered in excess, among other things, can also be accepted, in particular when a replacement of the liquid quantity delivered in excess with new operating liquids is required or desired.

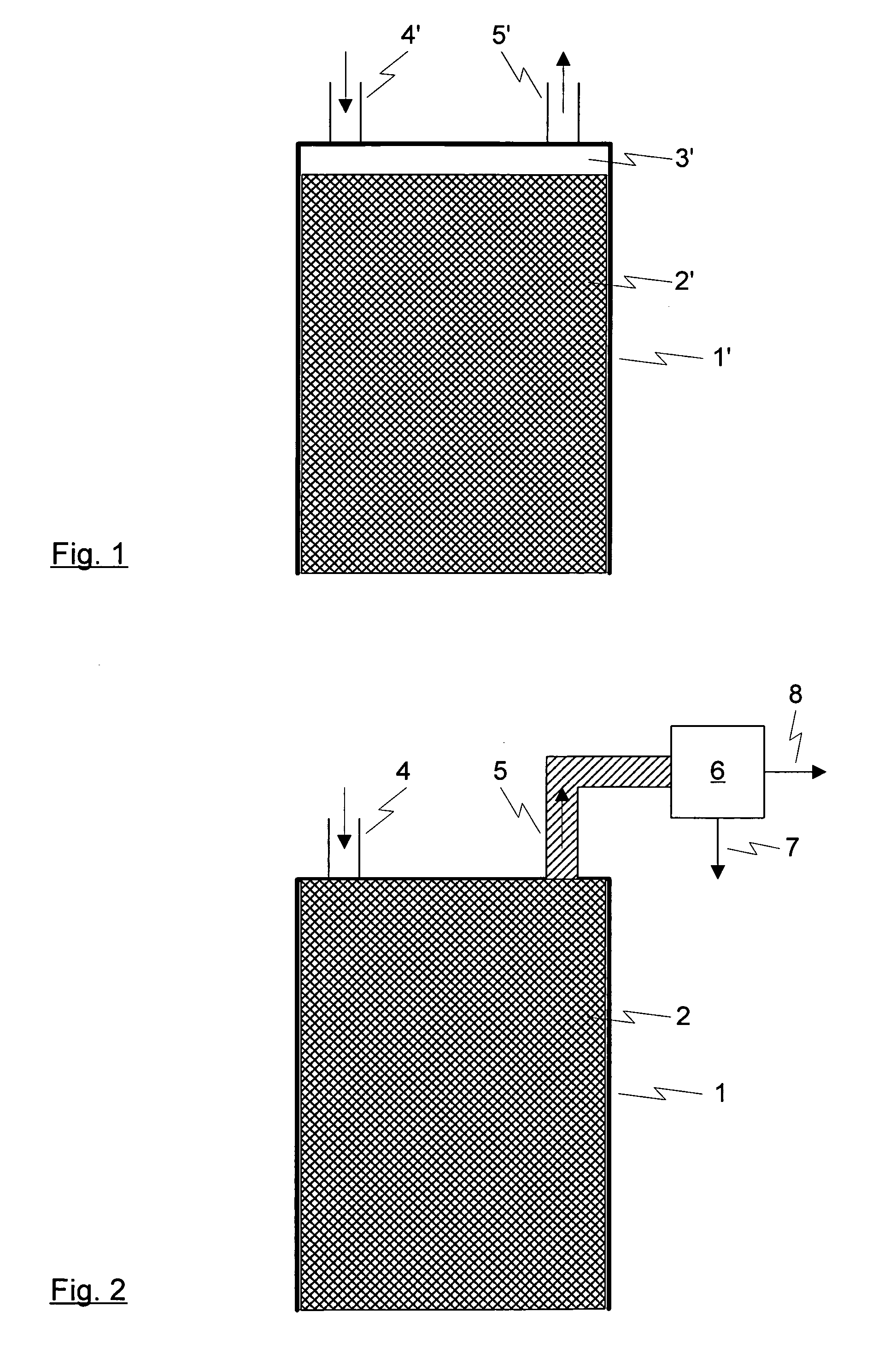

[0017]The method according to the invention for operating a pistonless compressor as well as further embodiments thereof, which represent objects of the dependent patent claims, shall be specified in detail below by means of the exemplary embodiment illustrated in FIG. 2.

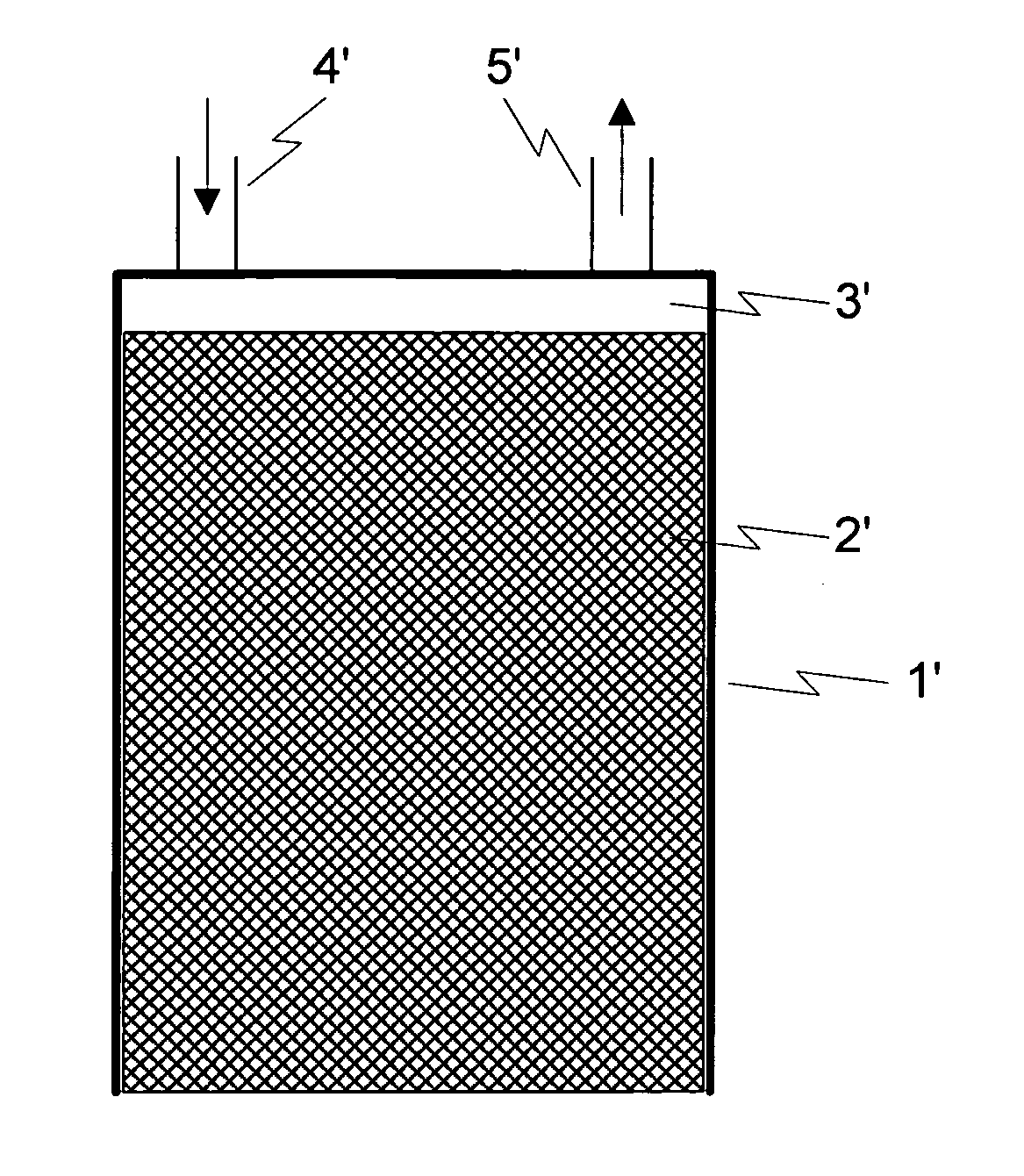

[0018]As already shown in FIG. 1, FIG. 2 also shows a schematized secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com