Pool coping and method for fabricating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

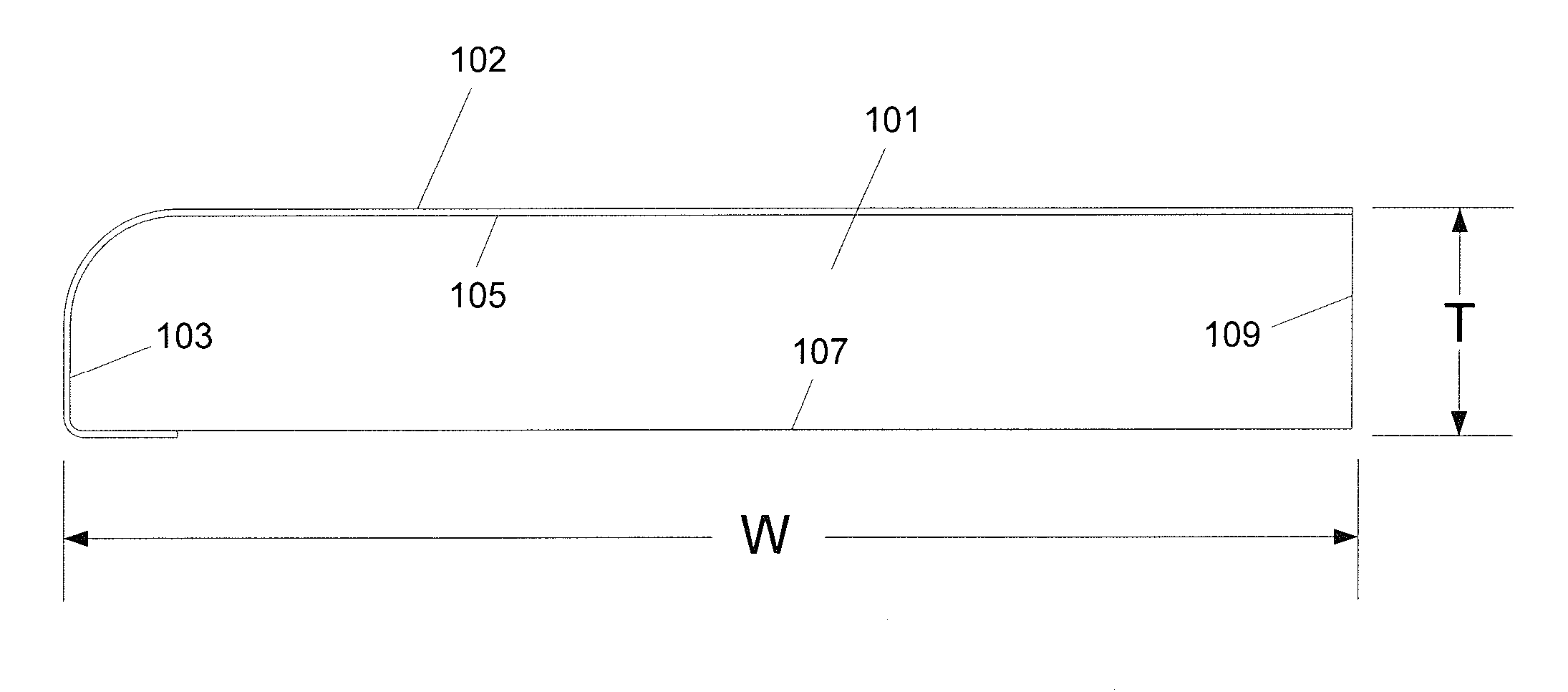

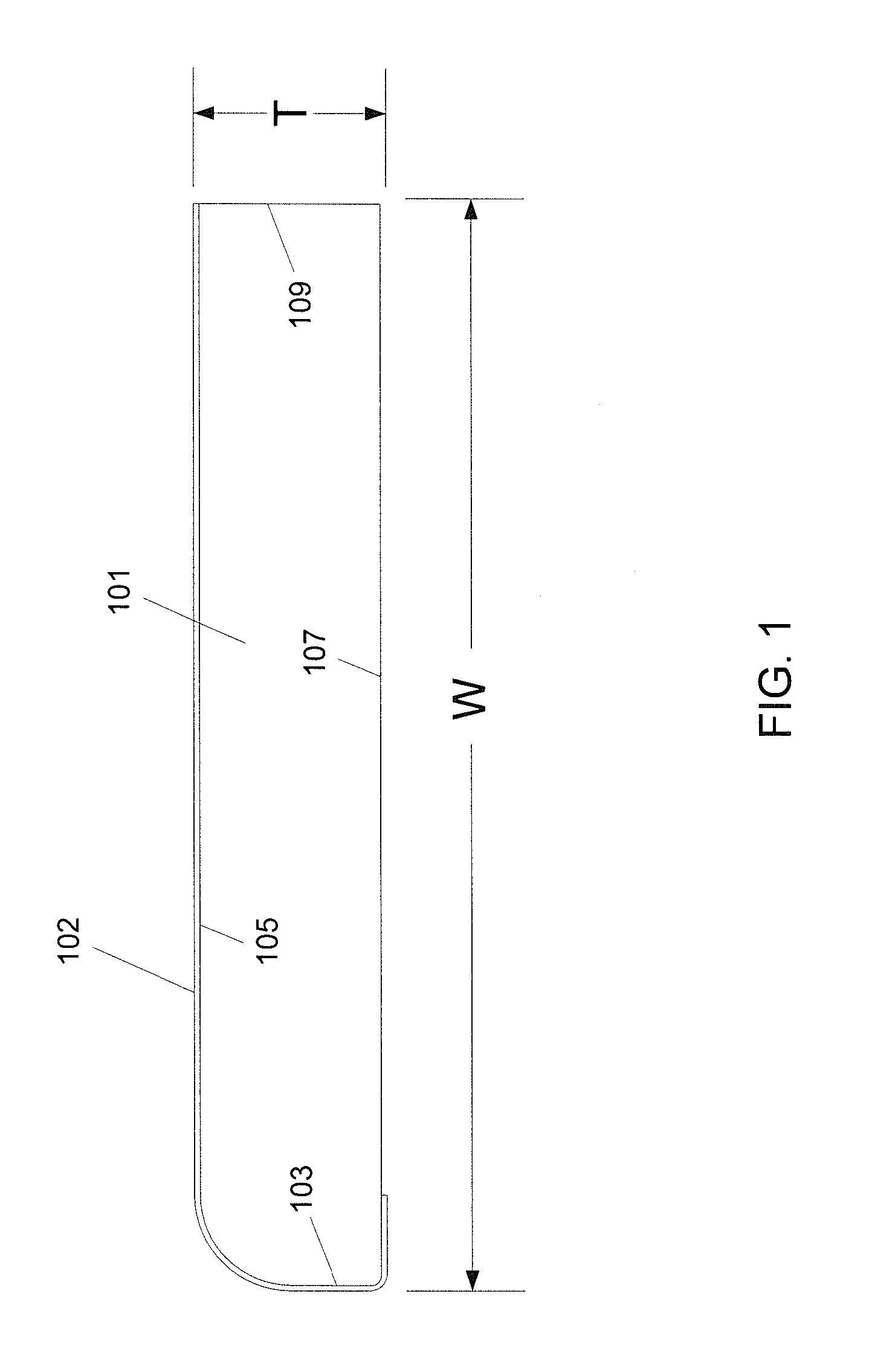

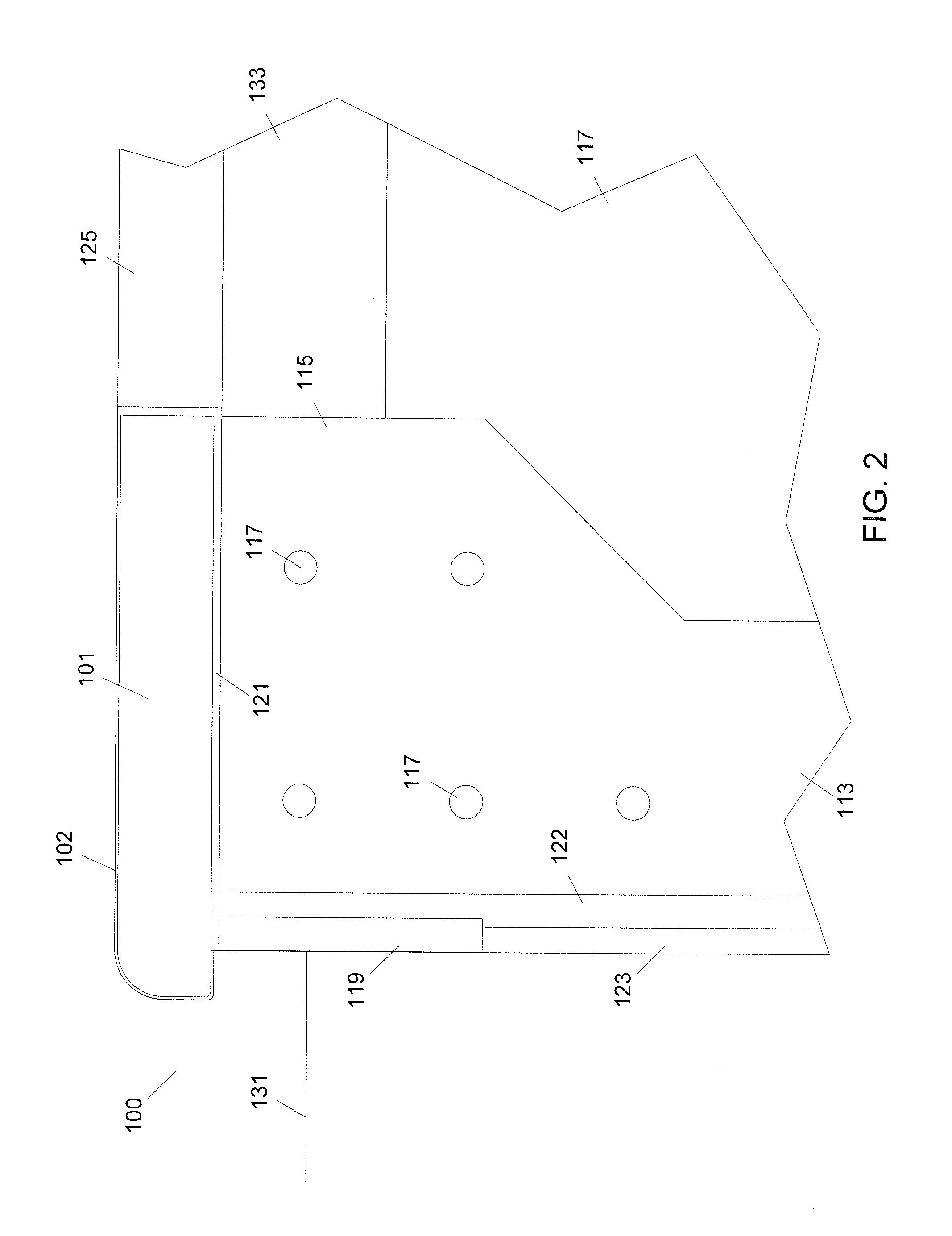

[0017]The present invention is directed towards an improved pool coping which is made of rubber rather than concrete. The inventive rubber coping has various advantages over the prior art. The rubber coping is an elastic material that is much softer than concrete and able to absorb the impact energy so the impact of a person falling on the rubber coping may cause less injury than if the person fell onto a concrete coping. The hardness and the rigidity of concrete coping can be many times greater than that of rubber coping. Thus, pools that use the inventive rubber coping may dramatically reduce the potential for slip and fall injury compared to concrete coping.

[0018]The rubber coping is also significantly lighter than concrete coping. The rubber coping can be about 60% lighter than concrete coping of the same size. The density of concrete can be about 180 pounds per cubic foot and the density of rubber can be about 74 pounds per cubic foot. Thus, a coping piece that is 24 inches lon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap