Filling system for filling a travel dispenser

a technology for filling systems and dispensers, which is applied in the direction of liquid handling, single-unit apparatuses, packaging goods types, etc., can solve the problems of not easy to determine when the reservoir of the travel dispenser is full, the pump is electrical, and thus needs electrical power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

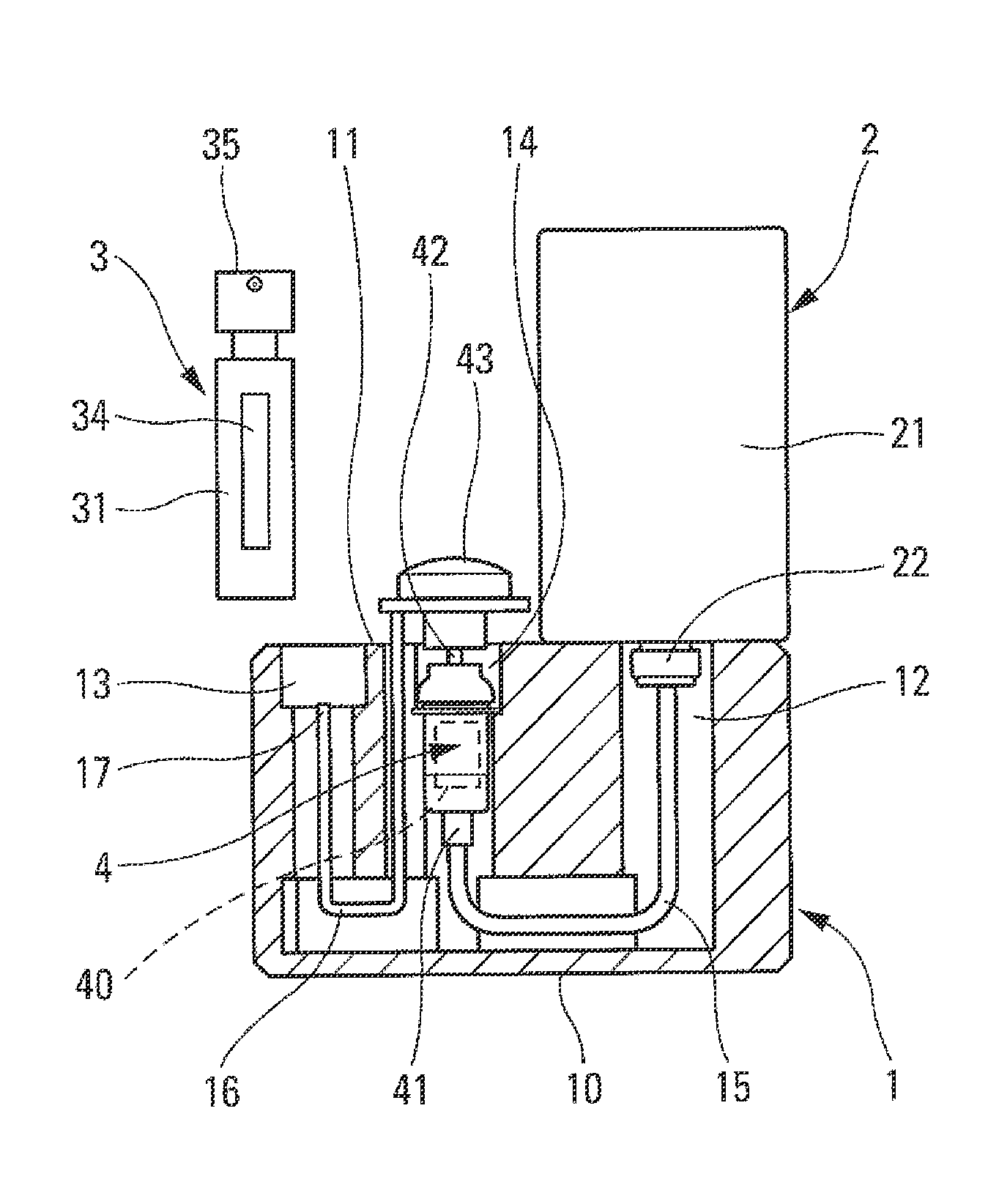

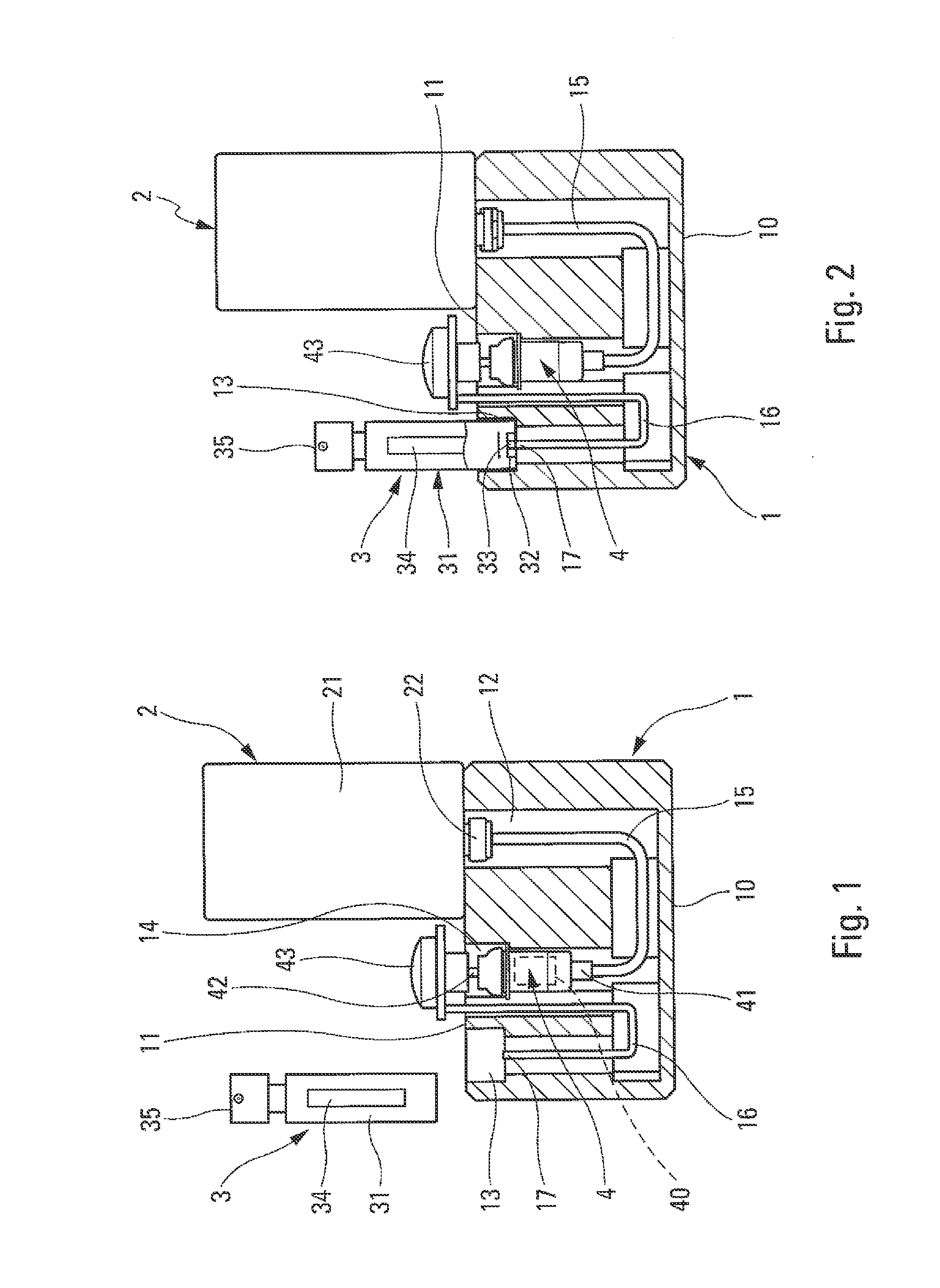

[0029]In the first embodiment in FIGS. 1 and 2, the pump defines an inlet 41 that is connected to the supply 2 via the duct 15. The pump defines a pump chamber 40 presenting its maximum volume in its rest position. The pump 4 also includes an actuator rod 42 on which there is mounted a pusher 43 that acts as an actuator member. The duct 16 is connected to the pusher 43, or, in a variant, to another component element of the pump 4. By pressing on the pusher 43, fluid is taken from the supply 2 via the duct 15, and is delivered to the duct 16 having its end 17 opening the check valve 33 of the filling orifice 32 of the reservoir 31 of the travel dispenser 3. Advantageously, the maximum volume of the pump chamber 40 corresponds substantially to the determined maximum volume of the reservoir 31 of the travel dispenser, such that the reservoir 31 may be filled with a single actuation of the pusher 43. By way of example, provision may be made for the maximum volume of the chamber 40 to be...

second embodiment

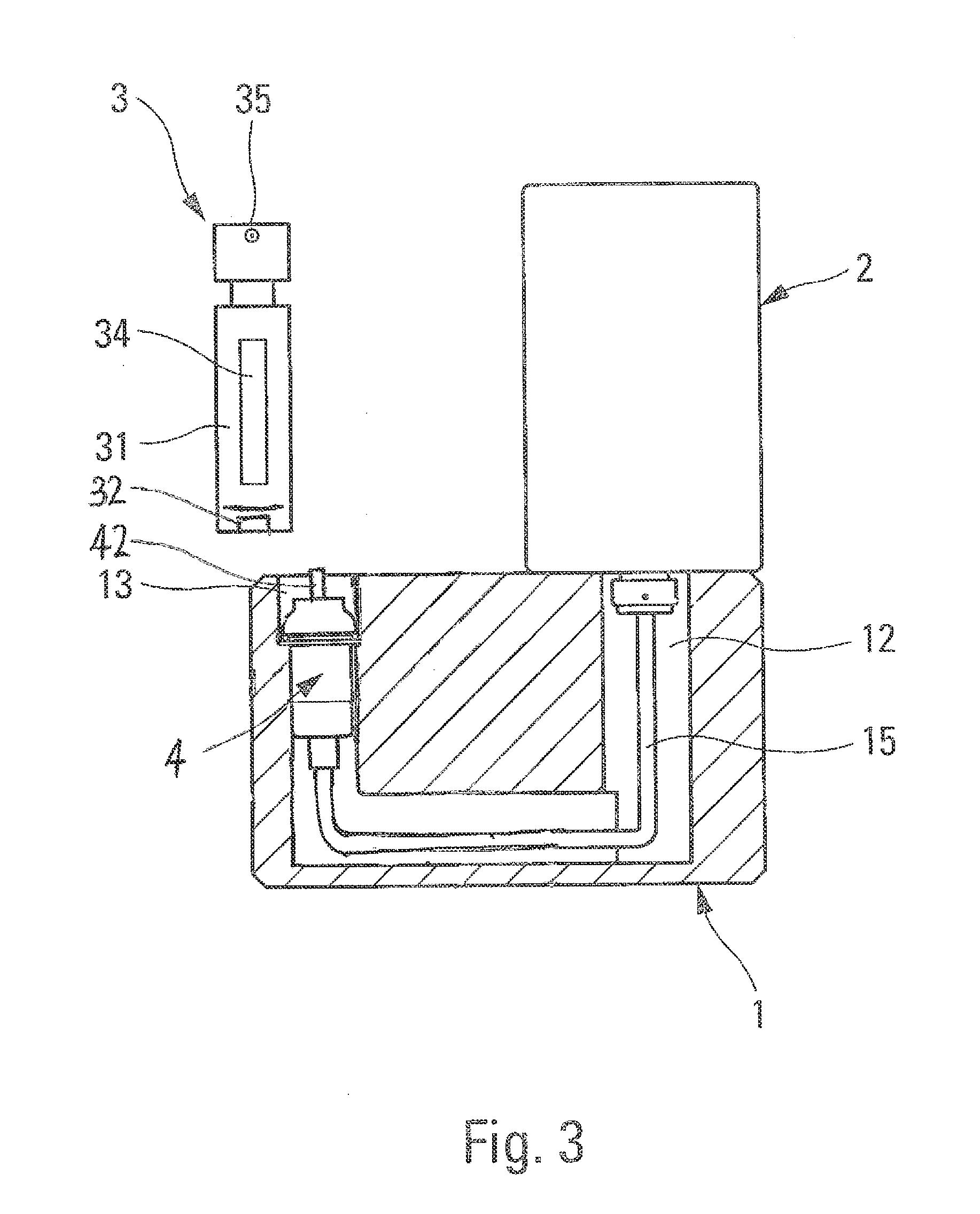

[0031]In the second embodiment in FIG. 3, the manual pump 4 is connected to the fluid supply 2 by a duct 15 and is located in the filling housing 13. The manual pump 4 comprises an actuator rod 42 that acts as an actuator member. The actuator rod 42 is located in the filling housing 13, in such a manner as to be actuated by the insertion of the travel dispenser. Thus, when the travel dispenser is pushed inside the filling housing 13 of the base 1, the actuator rod is depressed and the pump 4 dispenses a fluid product dose which corresponds roughly or precisely to the volume of the reservoir 31 of the travel dispenser. The travel dispenser is thus again refilled with fluid product.

[0032]Therefore, when starting from a completely empty state, the user does not even need to worry about how the dispenser means need to be actuated in order to fill the reservoir of the travel dispenser. Merely placing or inserting the travel dispenser in its filling housing 13 suffices to cause it to be f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| period of time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com