Selective collection system for recycling input materials having a monitor

a technology of input materials and monitors, applied in the direction of sorting, cocoa, waste collection and transfer, etc., can solve the problems of multiple issues in the separate store system of beverage input materials, environmental pollution and waste of resources, and material vertical size restrictions, etc., to achieve convenient maintenance, increase storage space, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

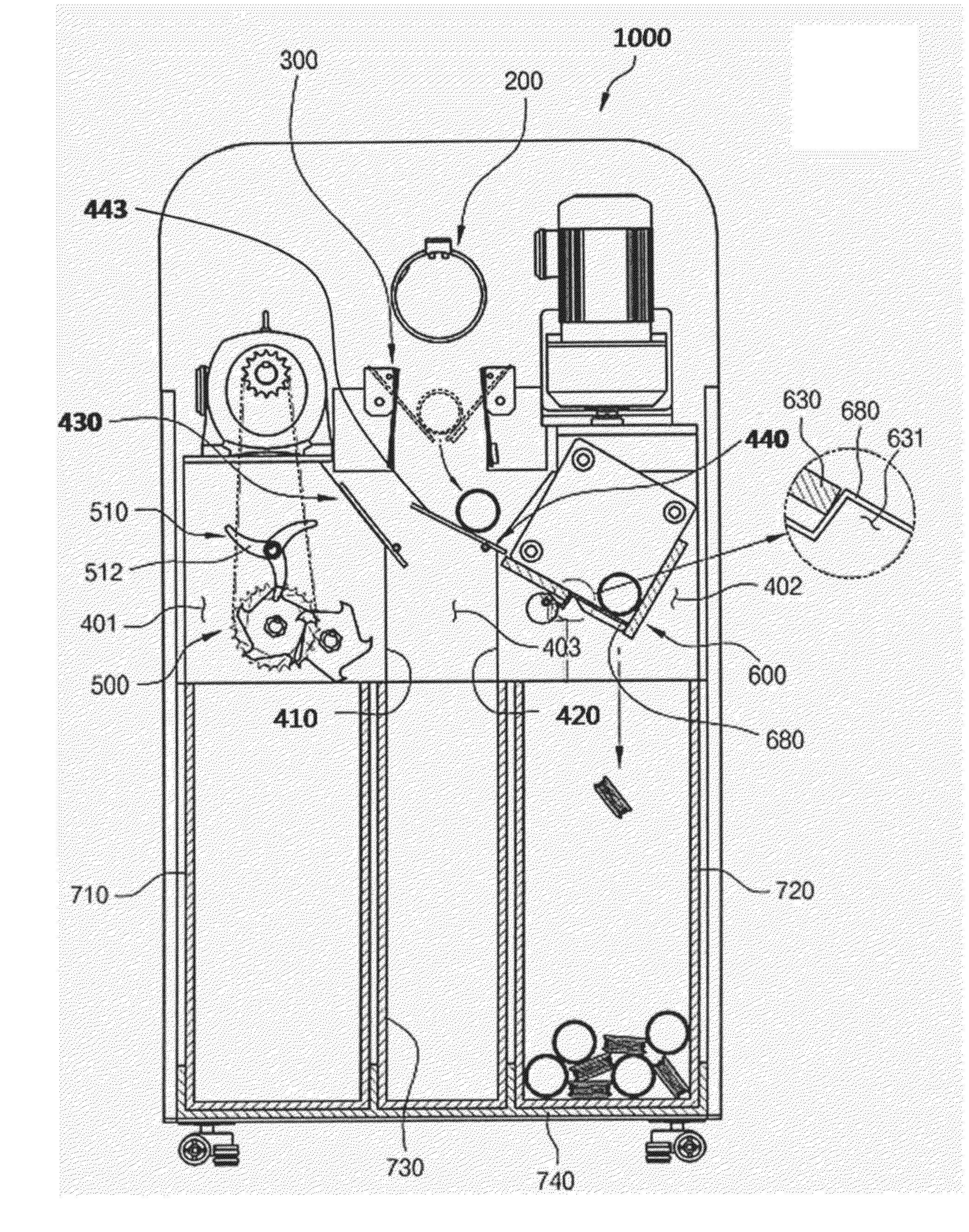

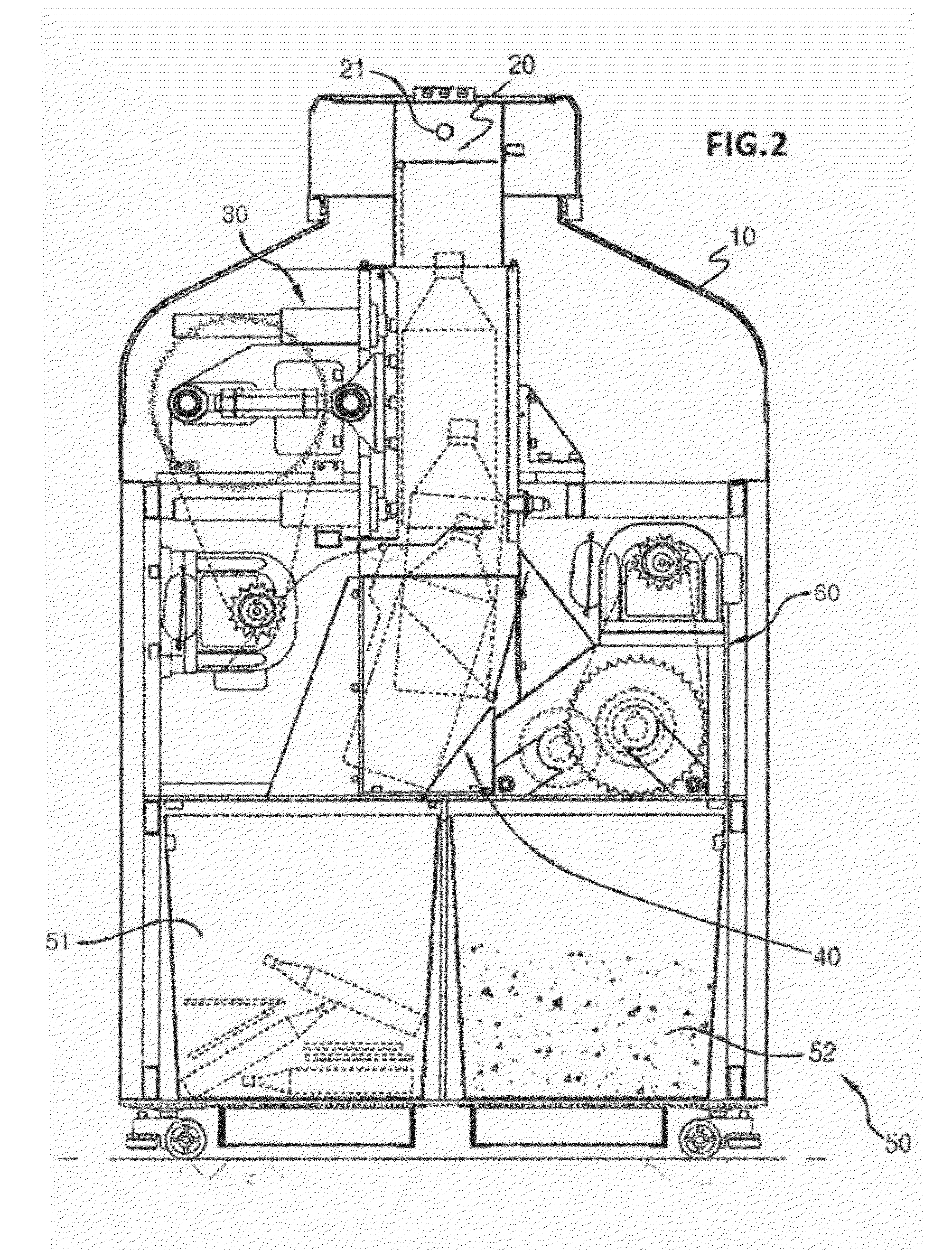

[0055]As illustrated in each figure, the selective collection system (1000) in accordance with an exemplary embodiment of the claimed invention comprises of a housing part (100), an input device (200), a material identification device (300), a sorting guide device (400), a shredding device (500), a compressing device (600), a collection part (700) and a control device (800). As exemplary shown in FIG. 4, the housing part (100) cases all of the internal components of the selective collection system (1000), including a front side panel (101) and a back side panel (102), which hold in place each component of the claimed selective collection system (1000). Although only the front side panel (101) and the back side panel (102) are shown in FIG. 4 and mentioned herein, the claimed selective collection system (1000) includes other mounting plates of variable shape for holding other internal components in place.

[0056]As exemplary shown in FIGS. 3 and 4, the input device (200) is preferably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com