Structural improvement of a water drainer in a cistern

a technology of cistern and water drainer, which is applied in the direction of valve operation/release device, mechanical apparatus, transportation and packaging, etc., can solve the problems of increasing the extra cost of parts, difficult operation, and wasting a lot of time, so as to save working hours and parts cost, simple and fast operation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010]In order to explain the technique of the present invention clearly and completely, the present invention will now be described in reference to the drawings, like numerals referring to like parts throughout the drawings.

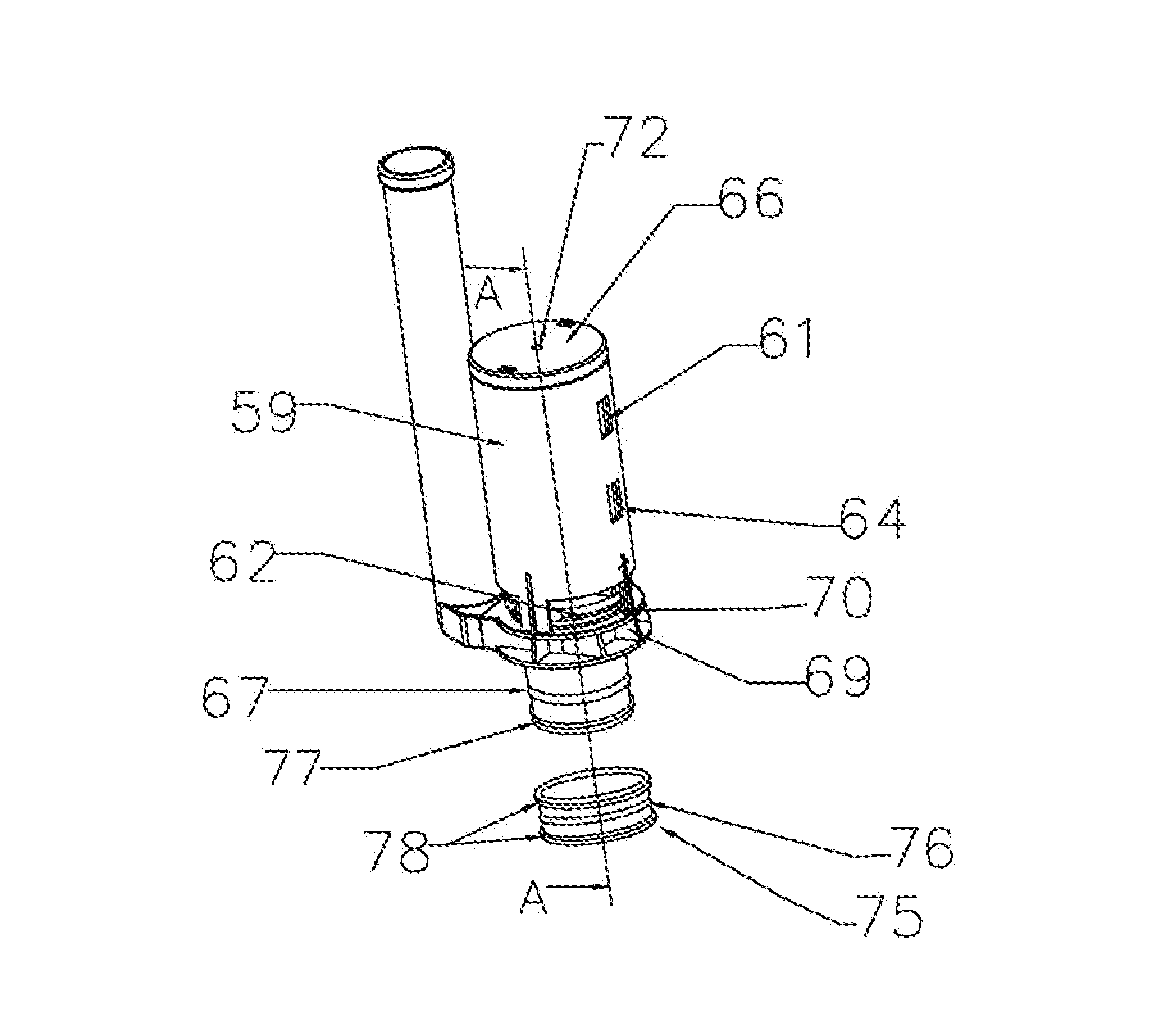

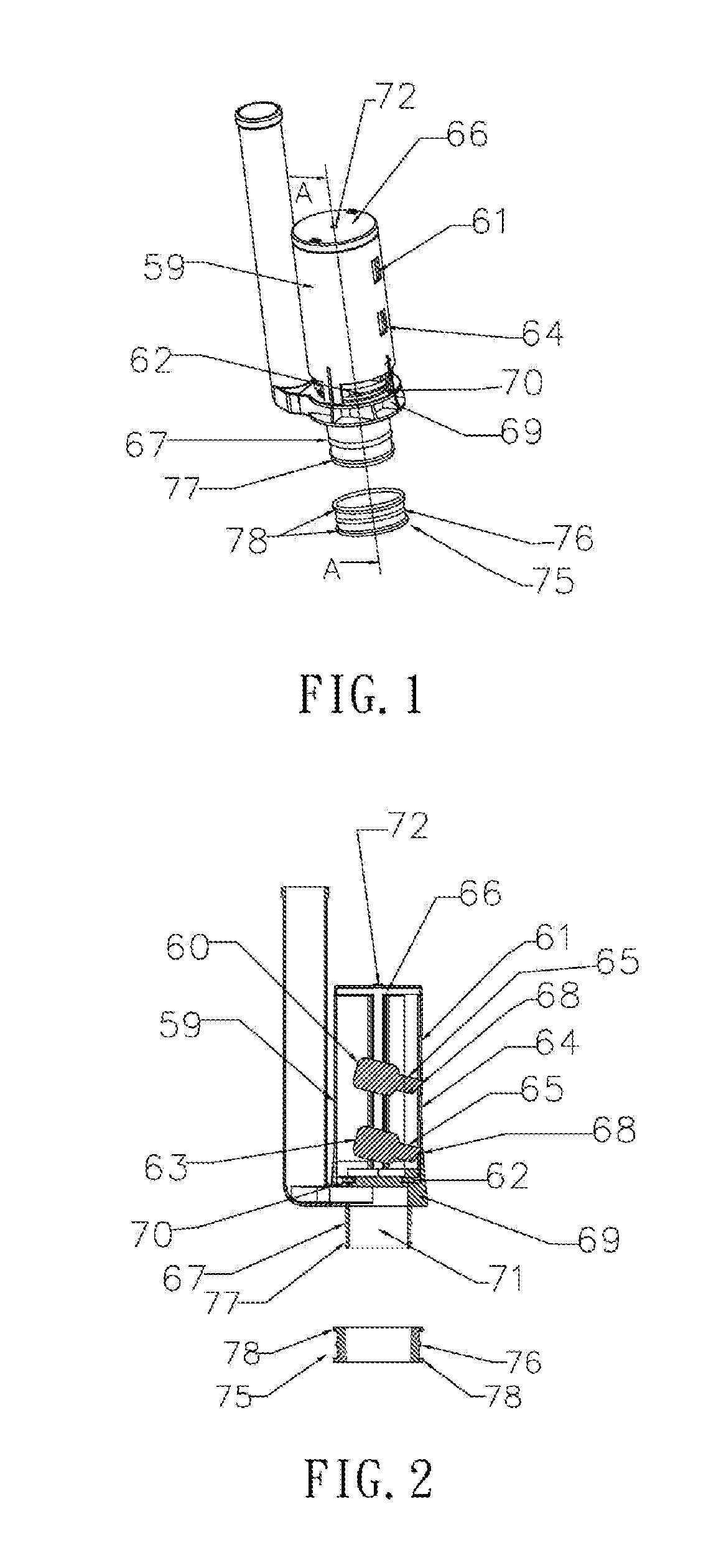

[0011]Please referring now to FIG. 1 to FIG. 2, there is illustrating a structural improvement of a water drainer of a cistern according to the present invention.

[0012]The water drainer comprises:

a moving module(66) which has a central hole(72), and has a flash valve(62) at bottom, and has upper float-ball(60) and lower float-ball(63) inside; at one end of the upper float-ball(60) and the lower float-ball(63) has a plate(65) separately; each plate has an engaging surface(68) on it;

a draining part (59) has an upper slot (61) and a lower slot (64); at the lower portion has a cylinder which is outside tapered; the cylinder has at least one or more than one of outer convex ring(67) and latch(77) on the surface; a base(69)is set up on the cylinder; the base(69) and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com