Liquid ejecting apparatus

a liquid ejecting apparatus and liquid technology, applied in printing and other directions, can solve the problems of inability to effectively squeeze the ink from the absorbent member, the contact member is difficult to drive and rotate, and the ink absorbency of the ink declines, etc., to achieve the effect of suppressing the liquid absorbency declin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

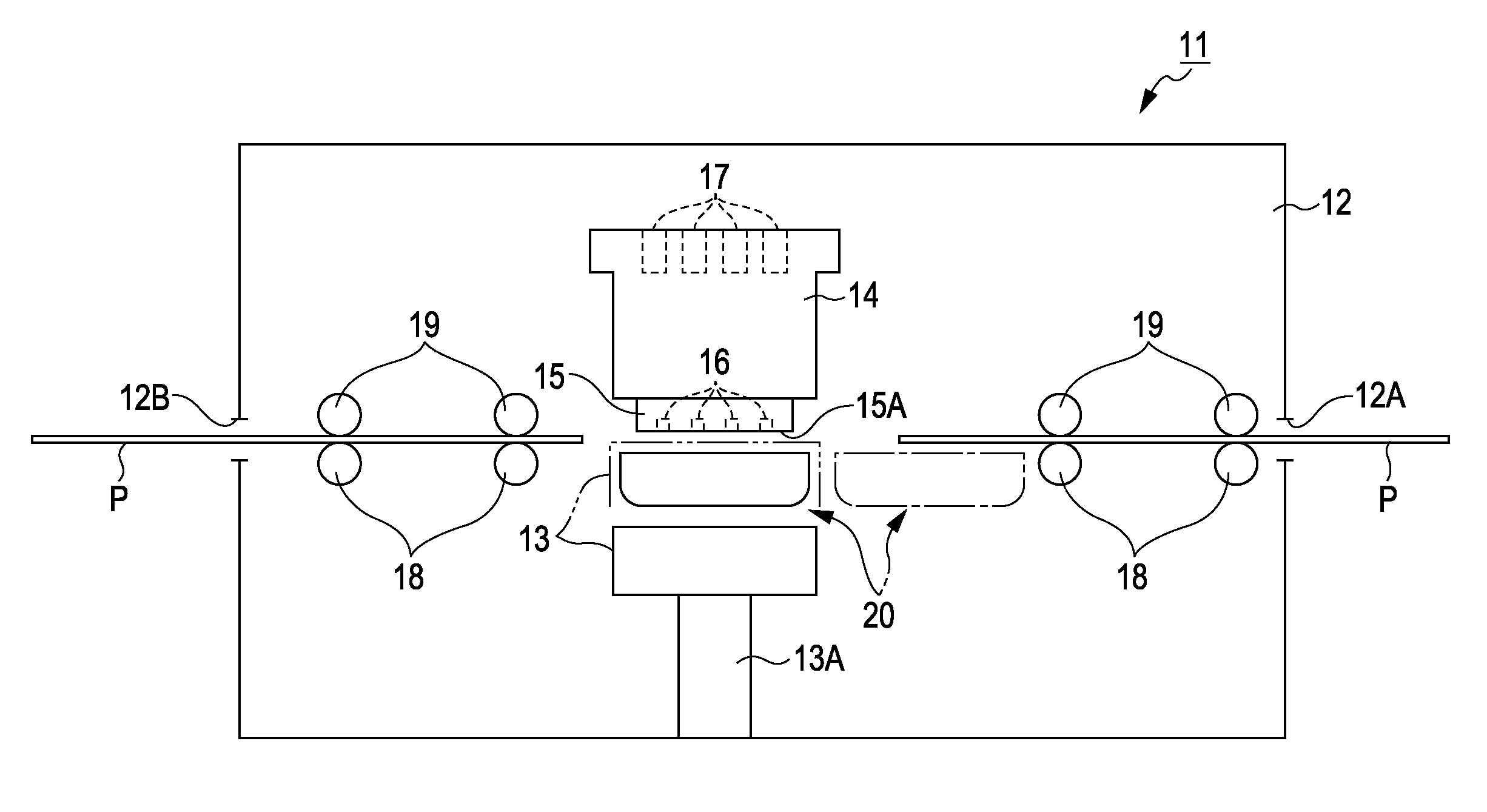

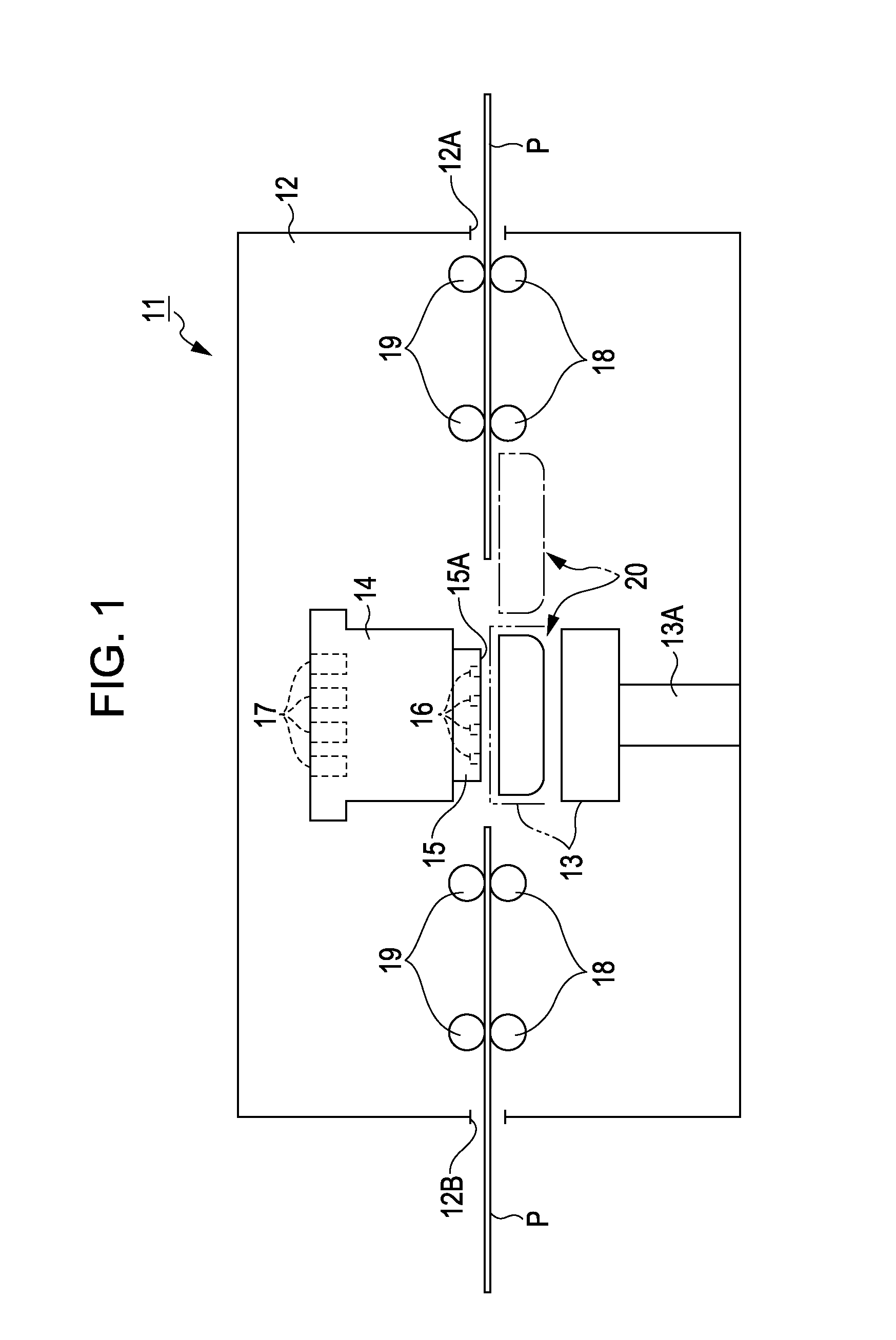

[0029]Hereinafter, Embodiment 1, which embodies the invention to an ink jet type printer as a kind of a liquid ejecting apparatus, will be described according to FIGS. 1 to 7.

[0030]As shown in FIG. 1, a printer 11 has a box-shaped frame 12 serving as an exterior, and a support member 13 forming a rectangular shape when viewed from a plane is provided in a lower portion in the frame 12 from above. A longitudinal direction of the support member 13 corresponds to a horizontal direction in FIG. 1, and the support member 13 is vertically movable between a lower position shown by a solid line in FIG. 1 and an upper position shown by a two-dot chain line by a lifting device 13A.

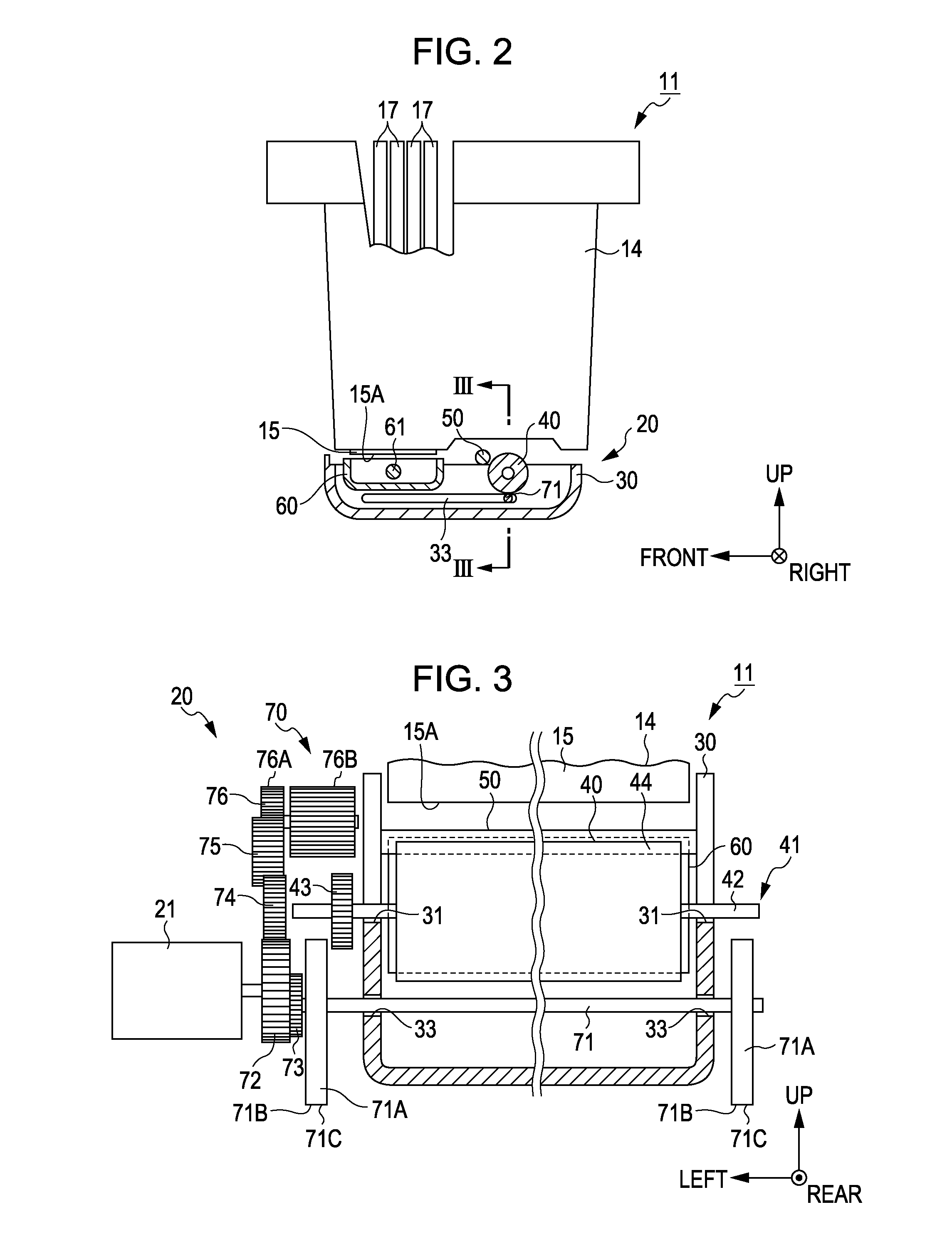

[0031]In the frame 12, at the position vertically facing an upper surface of the support member 13, a head cartridge 14 forming a rectangular box shape corresponding to the support member 13 is fixed, and a recording head 15 as an ejecting head is supported on the lower surface side of the head cartridge 14. On a no...

embodiment 2

[0070]The printer 11 of the embodiment differs from the head maintenance device 20 of Embodiment 1 in the following points. That is, the printer 11 of the embodiment has a transmission portion 170 instead of the transmission portion 70. Furthermore, the arrangement of the contact member 50 is changed. In addition, the details different from the printer 11 of Embodiment 1 will be described below, and the configurations common to Embodiment 1 are denoted by the same reference numerals, and a part or all of the descriptions thereof will be omitted.

[0071]As shown in FIG. 8, the contact member 50 is placed on the lower side and the rear side of the wiper 40. When being located at the upper position, the wiper 40 is farthest from the contact member 50 and comes into contact with the nozzle forming surface 15A. When being located at the lower position, the wiper 40 is nearest to the contact member 50 and does not come into contact with the nozzle forming surface 15A.

[0072]The transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com