Control of Multi-Hulled Water Craft

a multi-hulled water craft and control technology, applied in the field of watercraft, can solve the problem of water craft body experiencing corresponding roll or pitch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

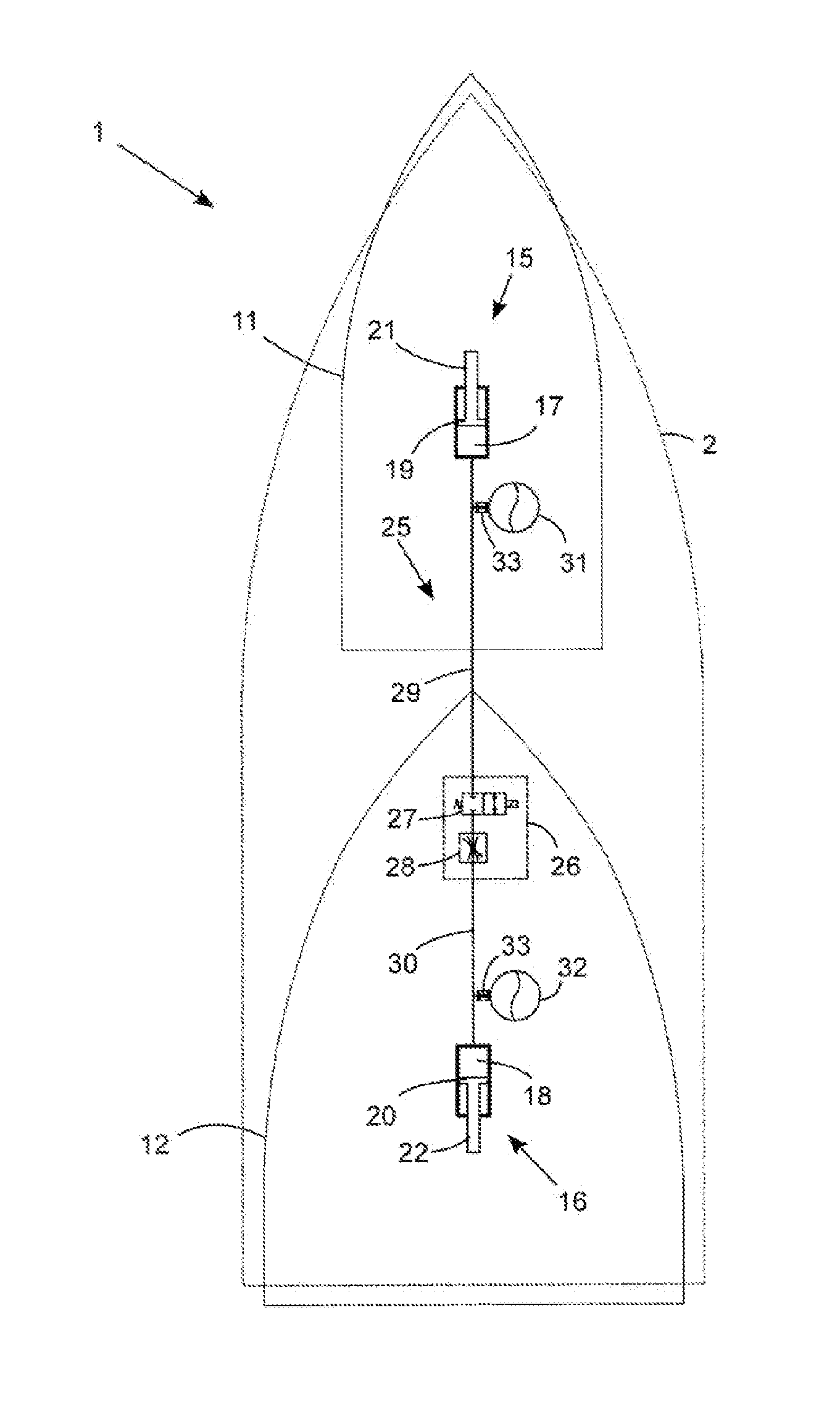

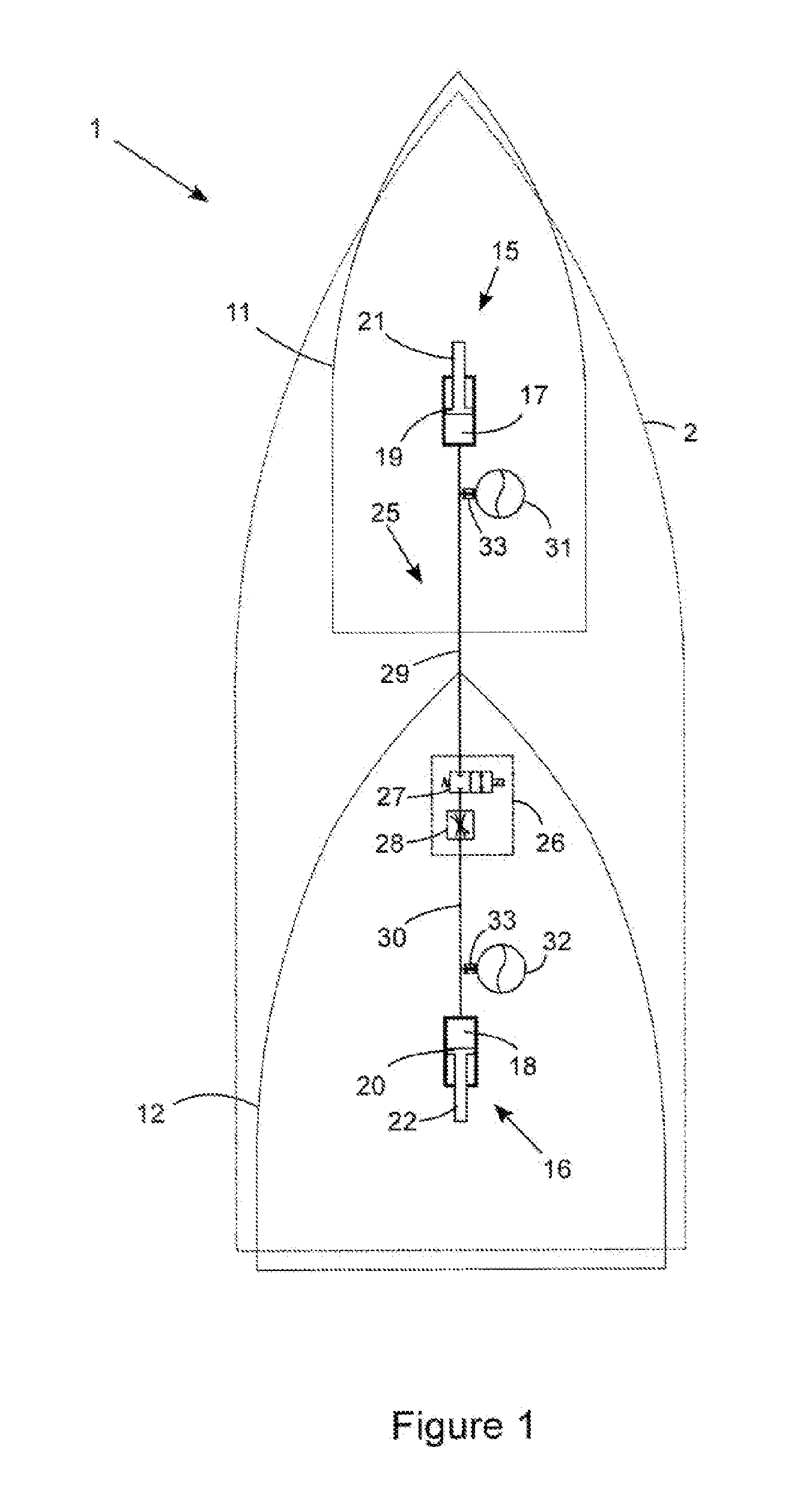

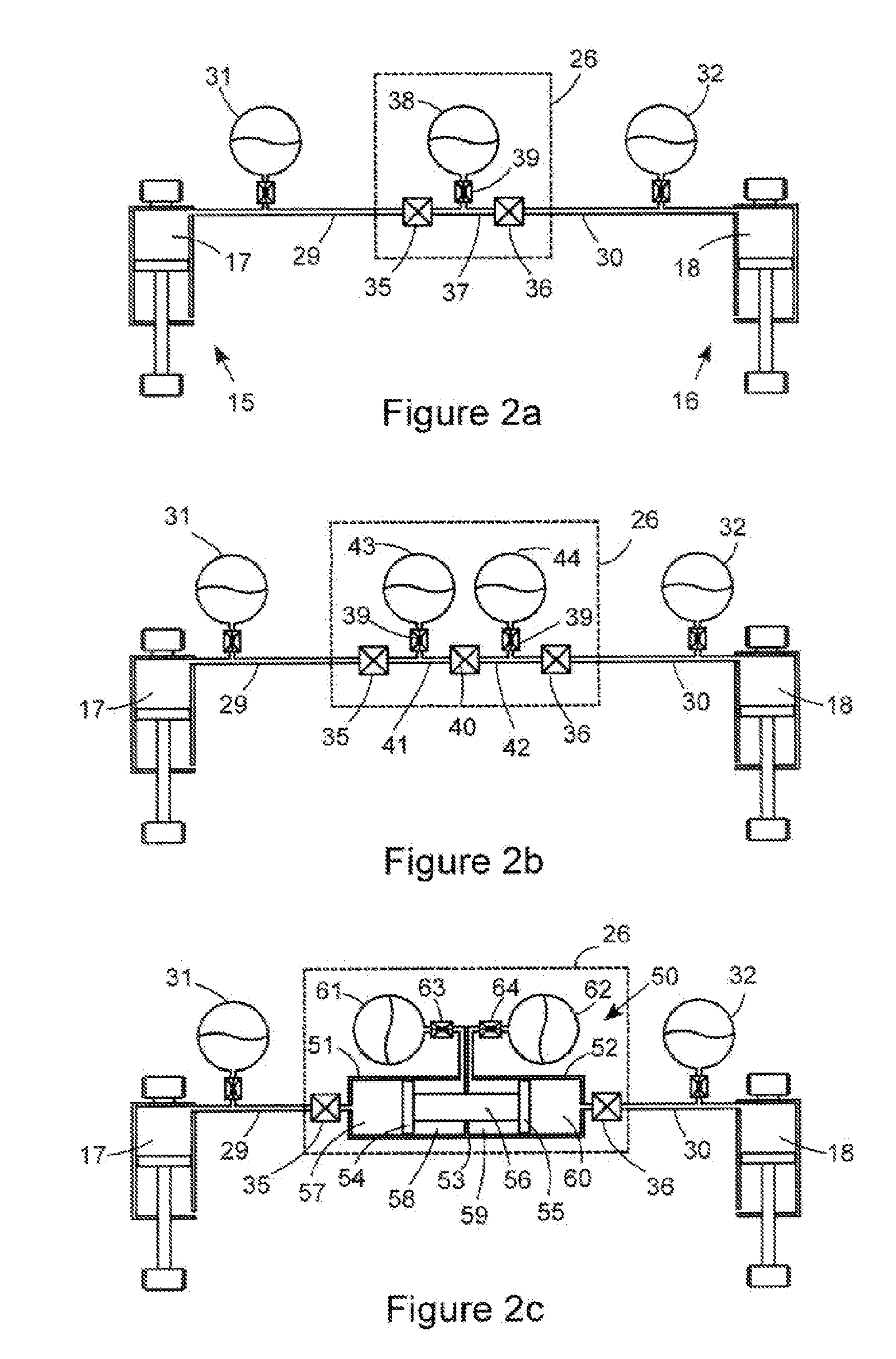

[0053]Referring initially to FIG. 1, there is shown a water craft 1 in accordance with an embodiment of the present invention. The water craft 1 includes a body portion or body 2, a front water engaging means 11, and a back water engaging means 12. Each water engaging means is located relative to the body by locating geometry (not shown) which permits generally vertical motion of the water engaging means with respect to the body. The locating geometry (i.e. locating means) for each water engaging means generally comprises one or more arms extending between and being pivotally connected to the body and the water engaging means. Each arm can have a number of shapes and types, for example if only one or two arms are used, they can be V-shaped (like a wishbone) or rectangular or any shape and form including box section portions to provide strength and fit in the space available for all desired positions of the water engaging means. The locating means can include any linkages commonly us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com