Tennis racket and method for manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

Example of Racket Configuration

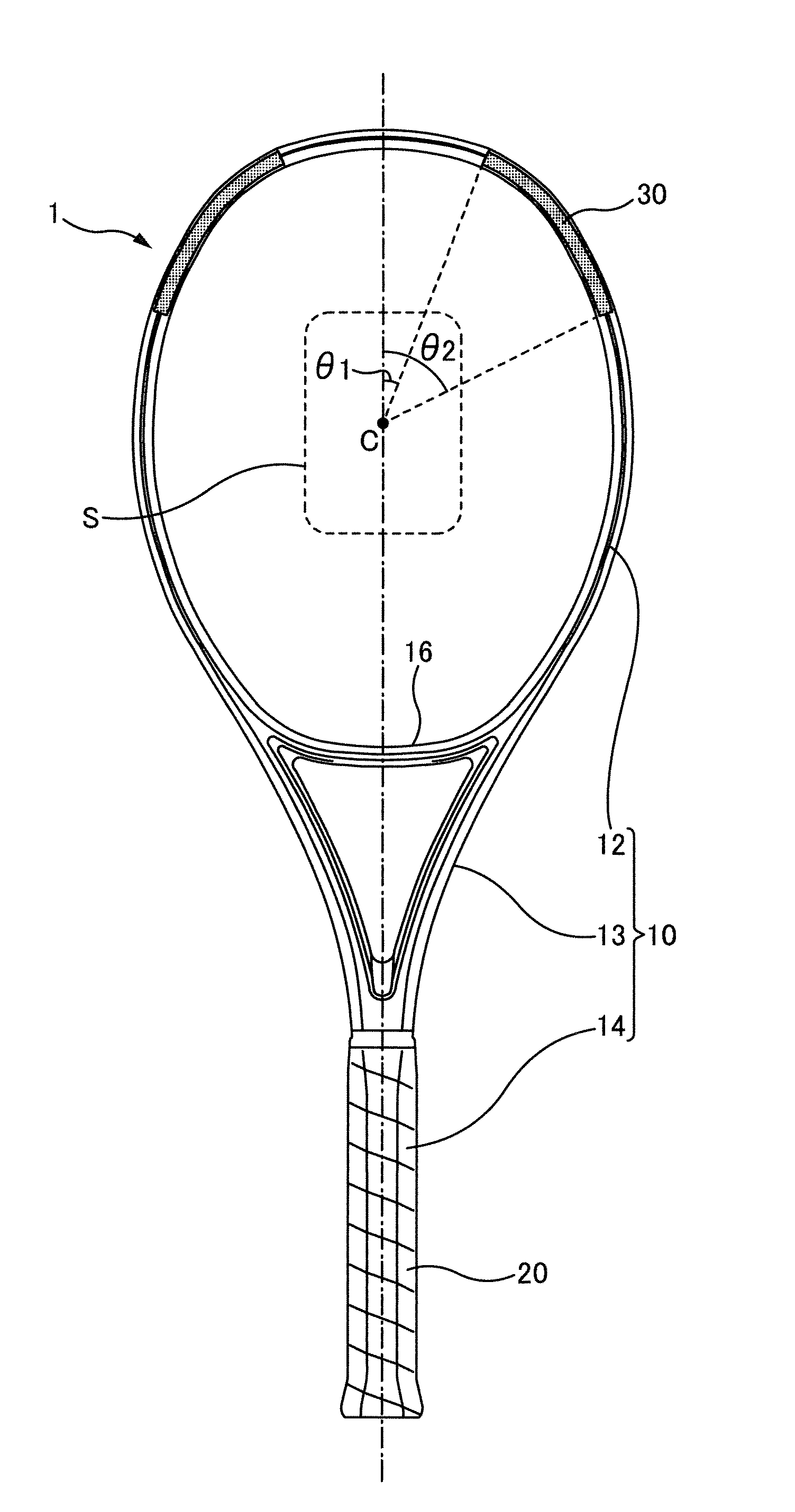

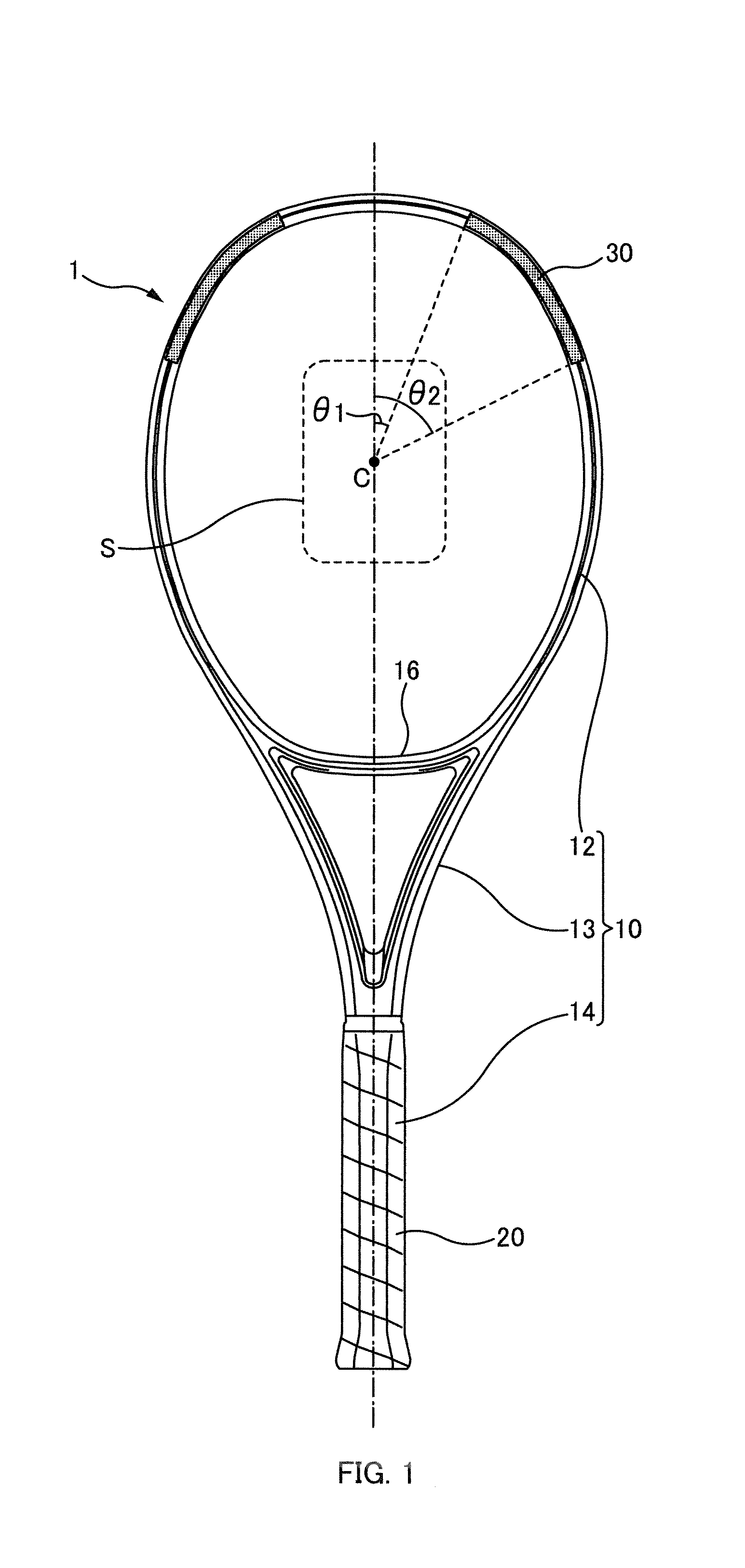

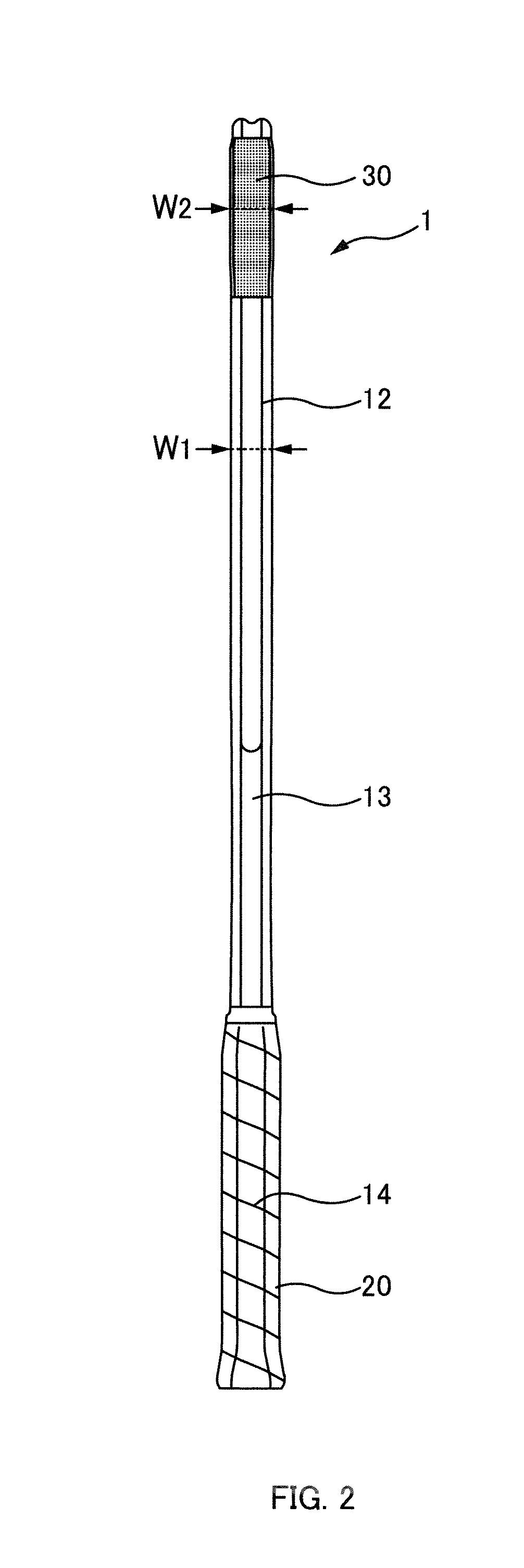

[0034]A configuration example of a tennis racket 1 according to the present invention will be described below with reference to FIGS. 1 and 2. FIG. 1 is a front view of the tennis racket 1 according to the present embodiment. FIG. 2 is a side view of the tennis racket 1 according to the present embodiment. Note that the upper side (with respect to the figure) of the tennis racket 1 shown in FIGS. 1 and 2 is called the tip side, and the lower side is called the base side.

[0035]As shown in FIG. 1, the tennis racket 1 of the present embodiment includes a frame 10 that is configured by a face portion 12 (corresponding to the frame portion), a shaft portion 13, and a grip portion 14.

[0036]The face portion 12 is provided in the top portion of the tennis racket 1 and is formed in a substantially elliptical shape. Insertion holes (not shown) for inserting a string are provided, in an inner circumferential portion and an outer circumferential portion of the fac...

embodiment

Present Embodiment

[0044]A method for manufacturing the tennis racket 1 of the present embodiment will be described below with reference to FIGS. 3A to 3D. FIGS. 3A to 3D are schematic diagrams showing the method for manufacturing the tennis racket 1.

[0045]The method for manufacturing the tennis racket 1 of the present embodiment has a foam material arranging step, a sheet tube forming step, a bending step, and a die molding step.

[0046]First, as shown in FIG. 3A, a carbon sheet 44 (which corresponds to a resin sheet) of prepreg fiber-reinforced resin (FRP) mainly made of carbon fiber is prepared, and the foam material 30 is arranged in areas that correspond to the hatched portions in FIG. 1. The foam material 30 is obtained by mixing a resin-based adhesive and a thermally expandable foam material, and forming the mixture into a sheet shape.

[0047]Note that in FIG. 3A, the midpoint of the carbon sheet 44 in the lengthwise direction (left-right direction in the figure) will become the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com