Bottle Carrier Made of Foldable Flat Material

a bottle carrier and foldable technology, applied in the direction of rigid containers, containers/bottles, containers with multiple articles, etc., can solve the problems of bottle carrier failure, inner handle walls that do not contribute to the interconnection of two connecting straps, etc., to improve rigidity and improve outward appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]While this invention may be embodied in many different forms, there are described in detail herein a specific preferred embodiment of the invention. This description is an exemplification of the principles of the invention and is not intended to limit the invention to the particular embodiment illustrated.

[0052]In the below explanation of different exemplary embodiments, similarly named components of different bottle carriers are provided with the same leading reference numbers, followed by a point and a subsequent, individual reference number. In summary, these components are also only labelled with the leading reference number, in particular in the list of reference numbers and in the claims.

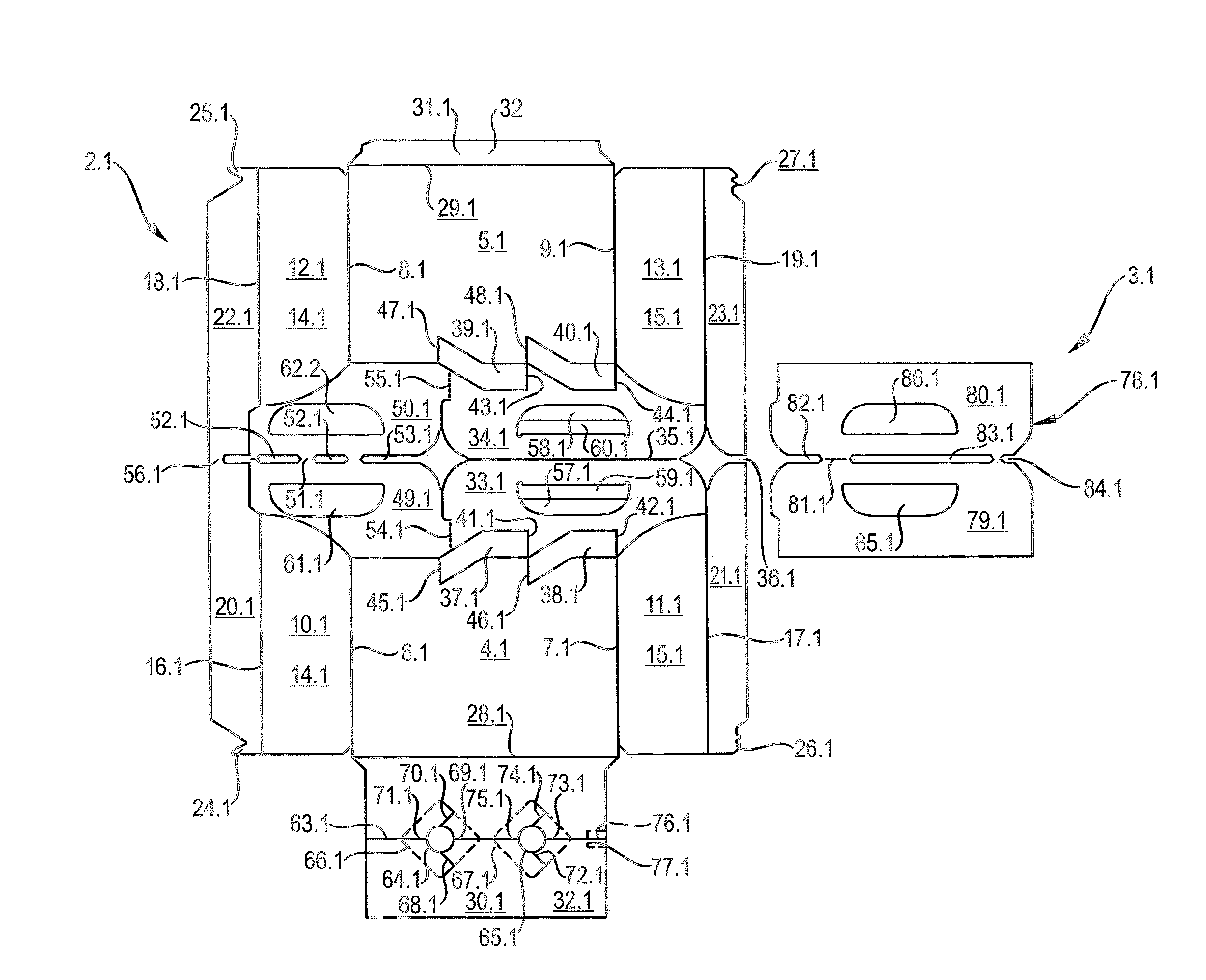

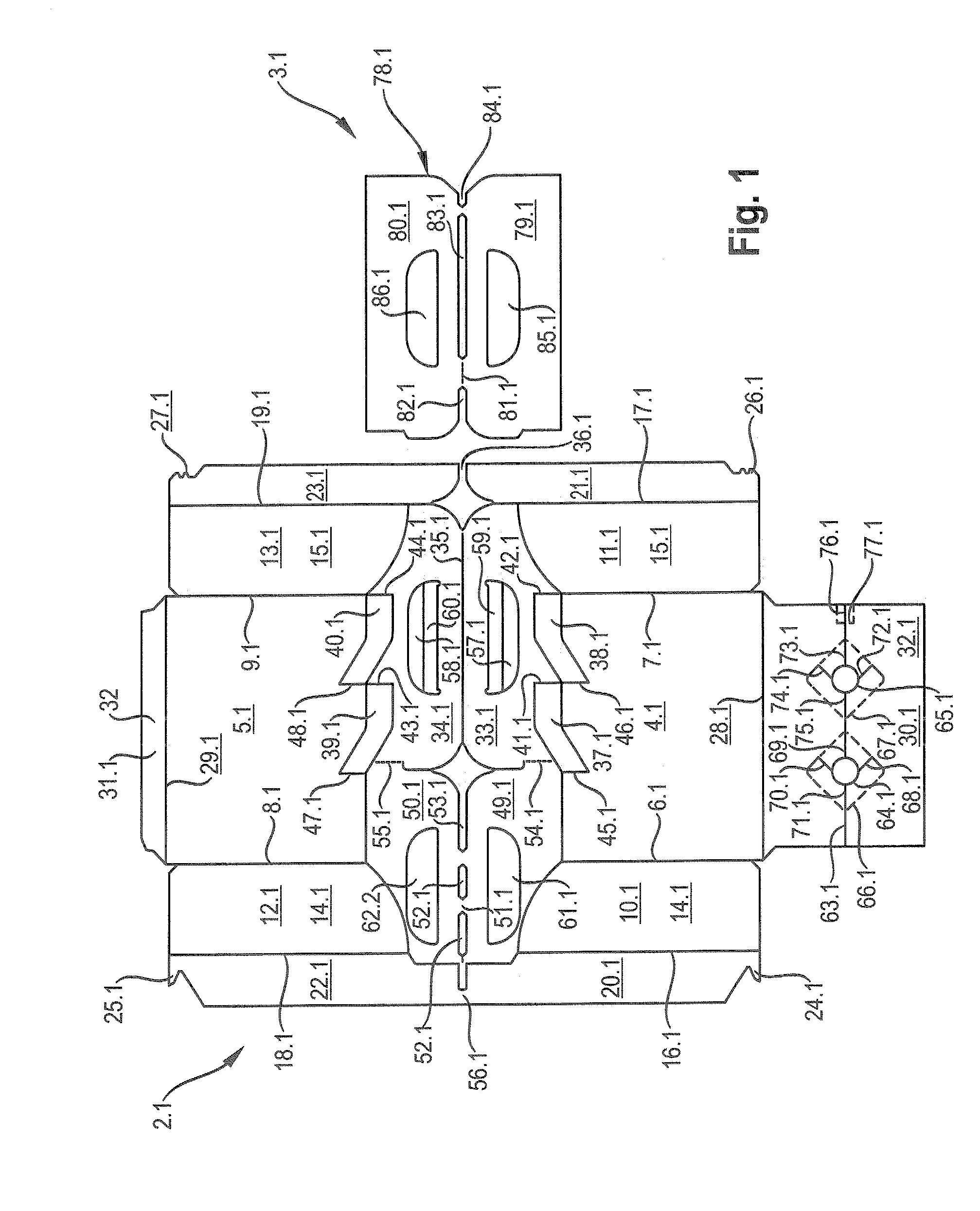

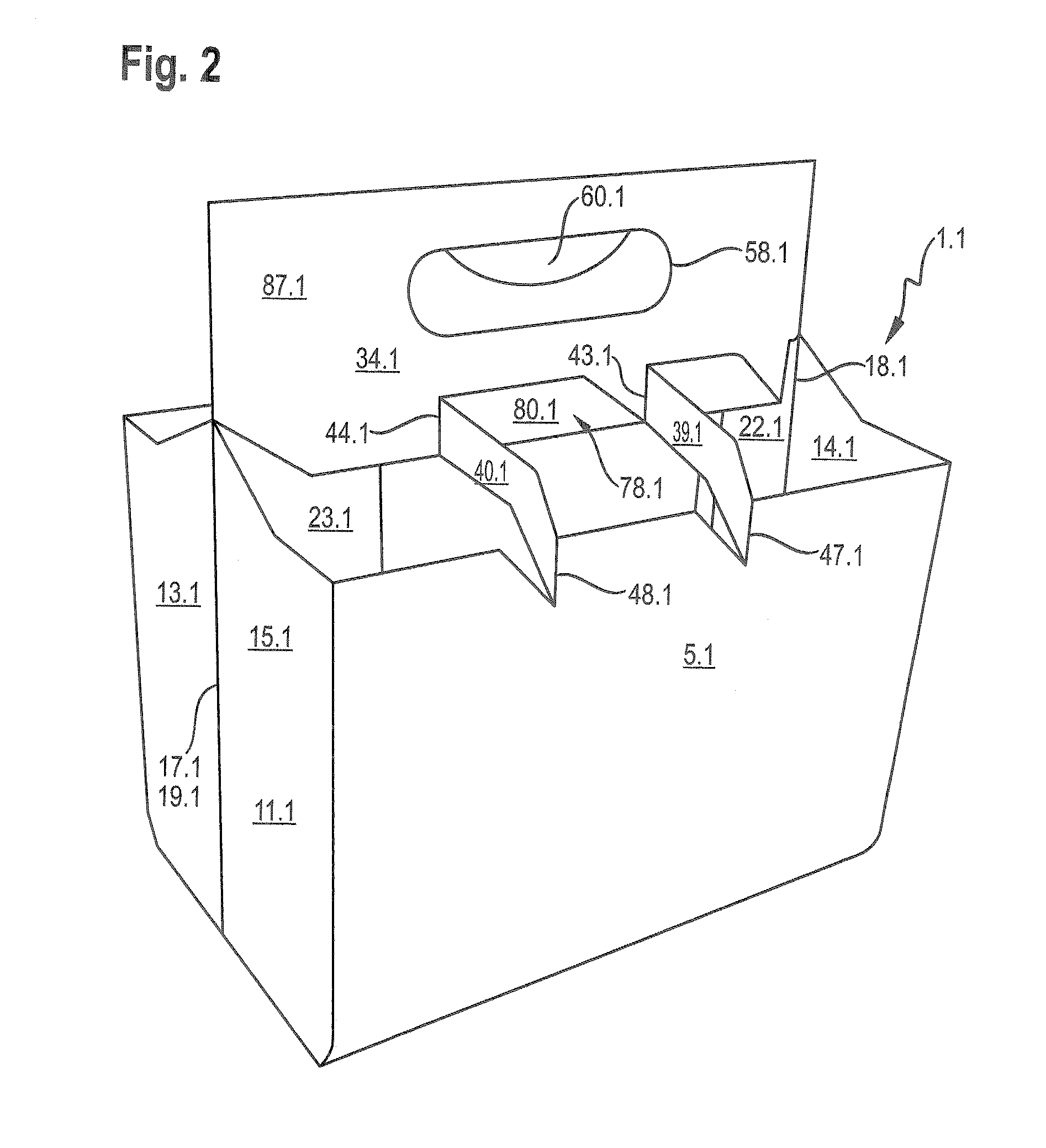

[0053]According to FIGS. 1 and 2, a bottle carrier 1.1 is formed from a blank 2.1 for the main part and a blank 3.1 for the insert.

[0054]The blank 2.1 comprises mainly rectangular longitudinal walls 4.1, 5.1, to which front wall sections 10.1 through 13.1 of two front walls 14.1, 15.1 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| filling volume | aaaaa | aaaaa |

| filling volume | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com