Screw cutting tool

a screw and screw technology, applied in the field of screw cutting tools, can solve the problems of increasing inventory and investment costs, reducing the service life of the screw, so as to facilitate the disposal of the endpiece and ensure the screw crop. the effect of accurate and secure screw cropping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

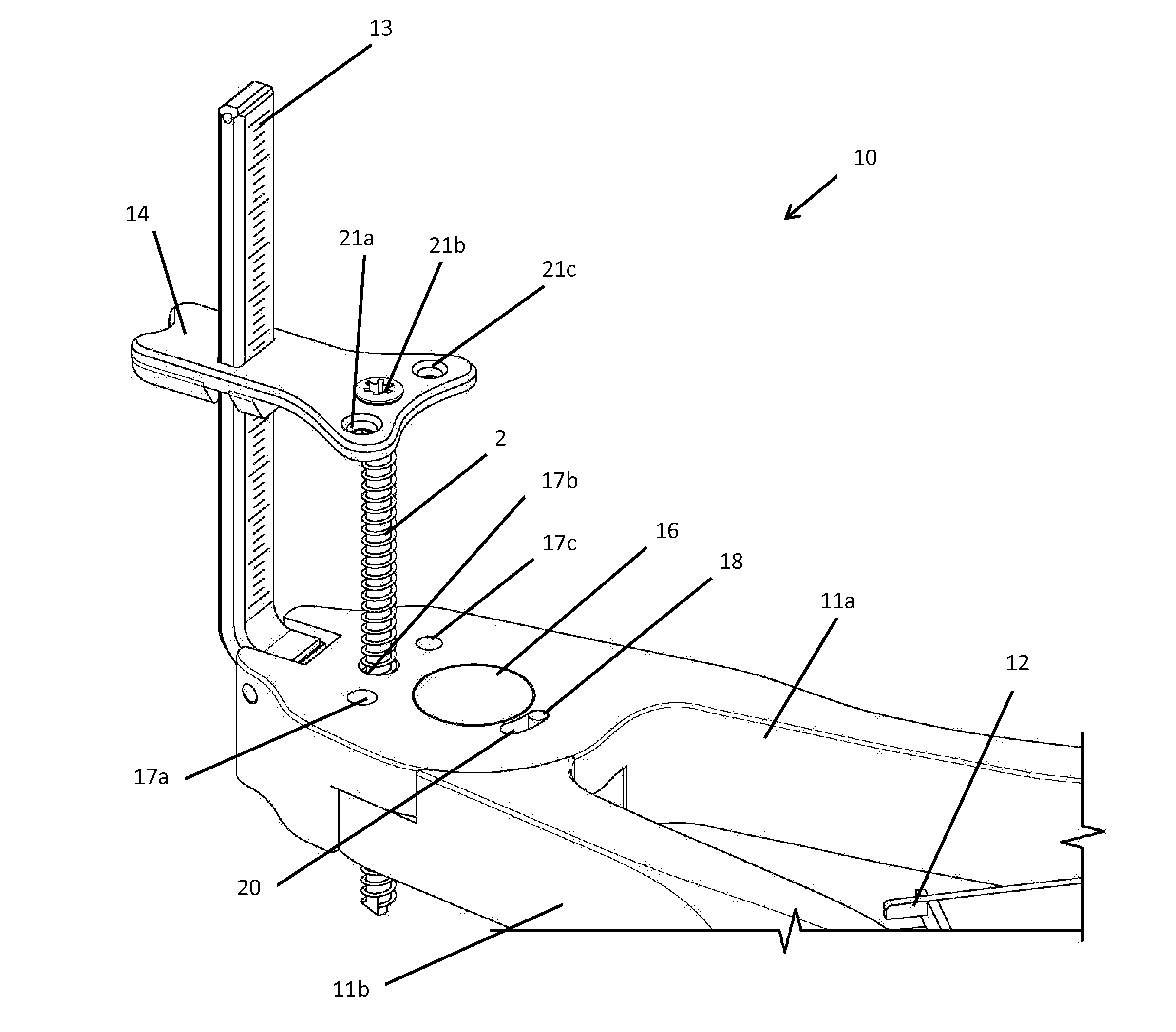

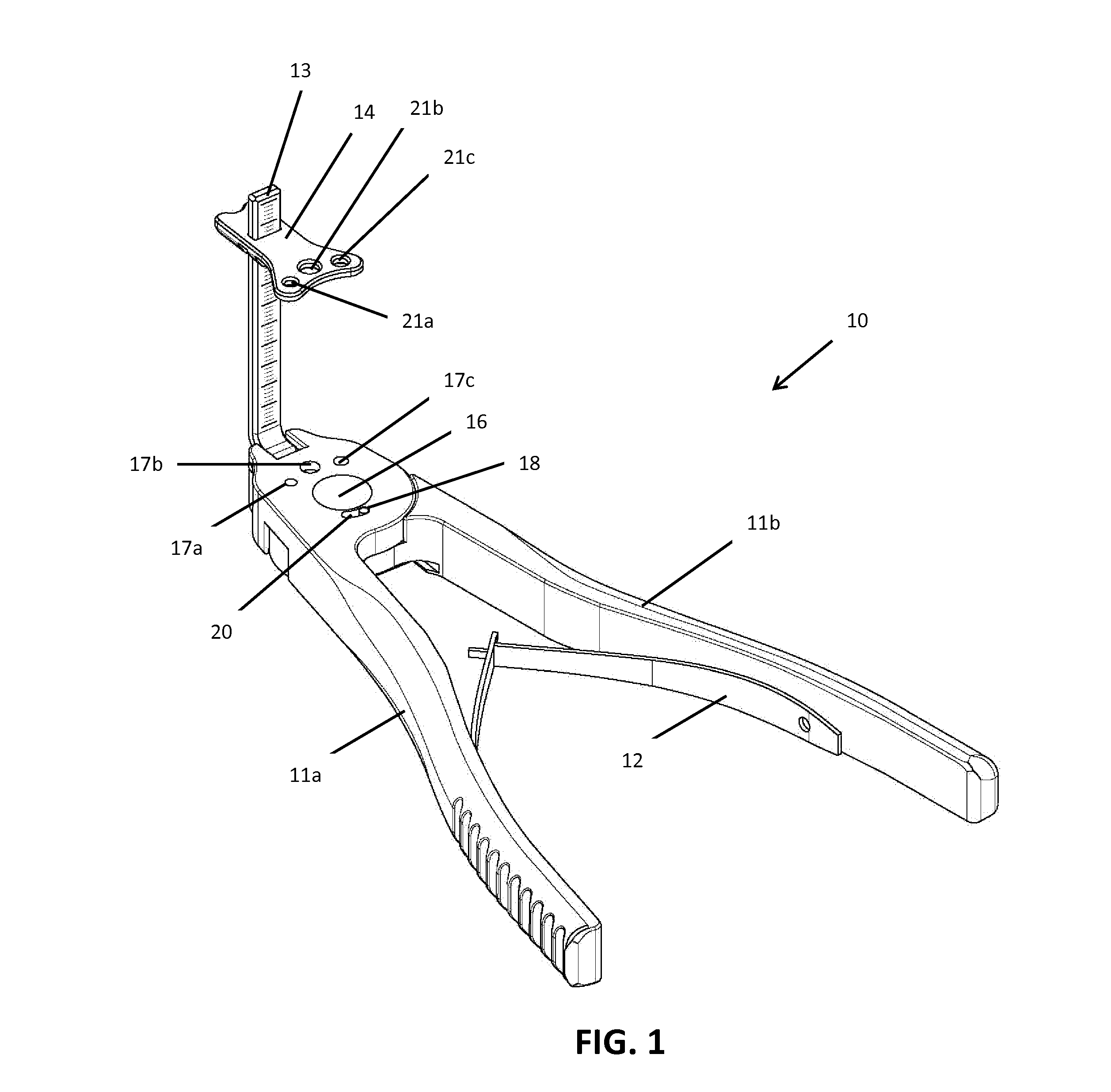

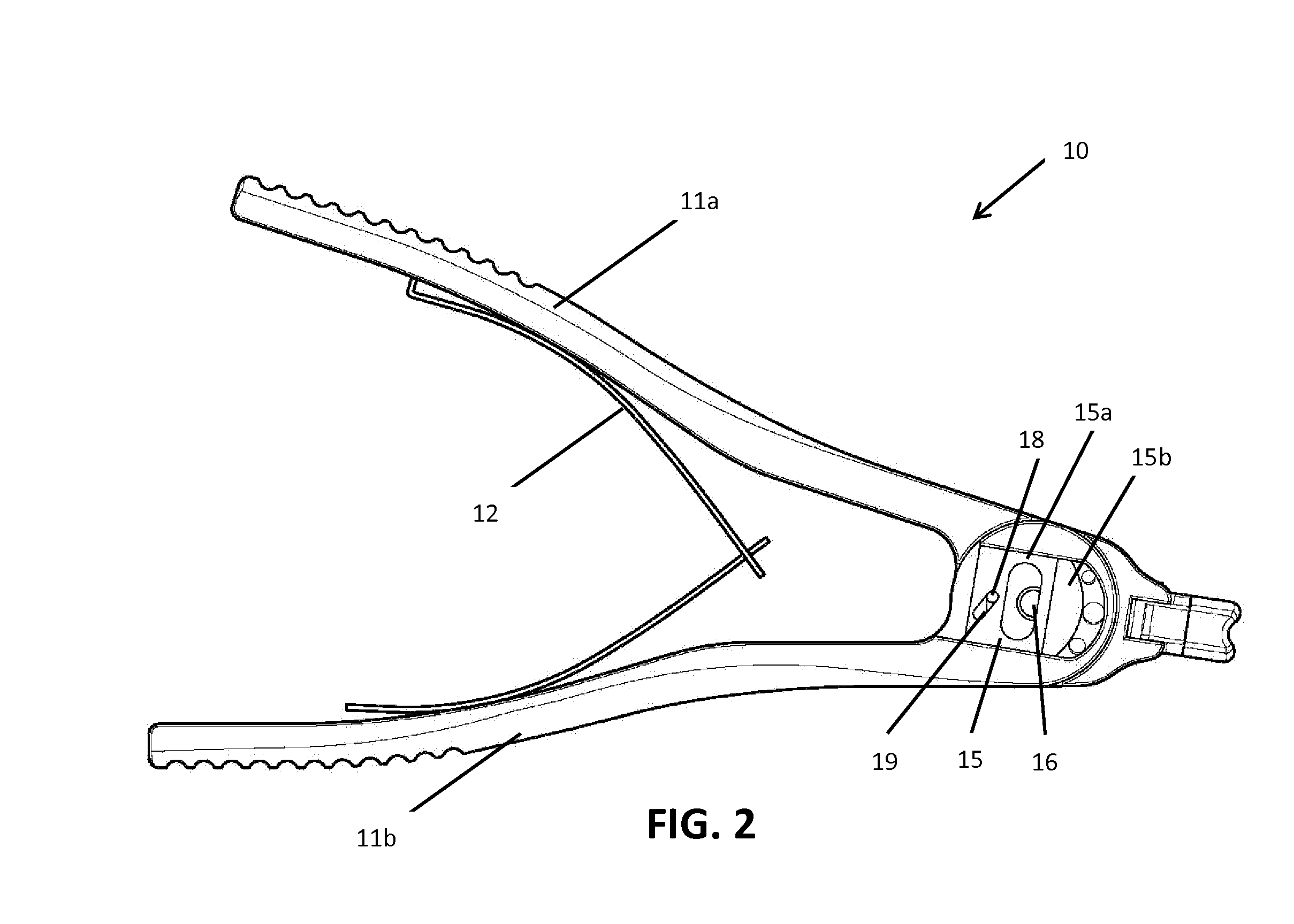

[0018]FIG. 1 shows a side view of one embodiment of screw cutting tool10. Screw cutting tool 10 includes first grip 11a and second grip 11b, which are connected at a pivot 16. Each grip 11a, 11b features a spring 12 that is positioned between the grips 11a, 11b to bias them in the open position. A measuring scale 13 features one or more scales drawn or etched thereon for precisely measuring screw length and is pivotally attached at the proximal end of the first grip 11a, with a screw holder 14 slidably attached to the measuring scale 13. The pivotal connection of measuring scale 13 to the first grip 11a allows for the scale to be rotated into a folded configuration for easier storage of the tool. Likewise, the slidable connection of screw holder 14 with measuring scale 13 allows for the easy manipulation of that element, as well as for its removal to ease storage of the tool. It is to be understood that the measuring scale 13 could alternatively be attached to the proximal end of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| lengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com