Loop thermosyphon cooling device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The technical contents of the present invention will become apparent with the detailed description of preferred embodiments accompanied with the illustration of related drawings as follows. It is noteworthy that the drawings are provided for the purpose of illustrating the present invention, but not intended for limiting the scope of the invention.

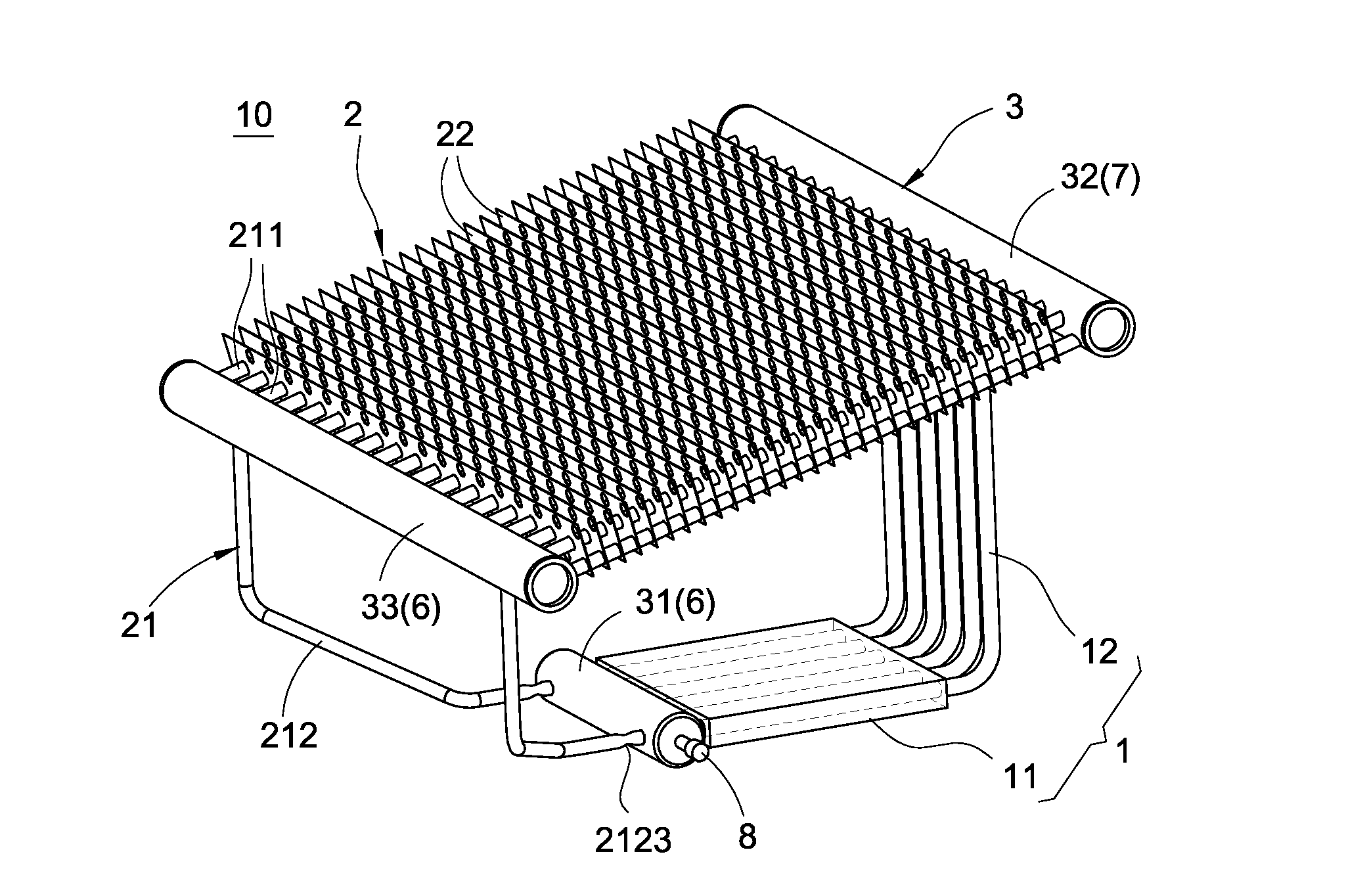

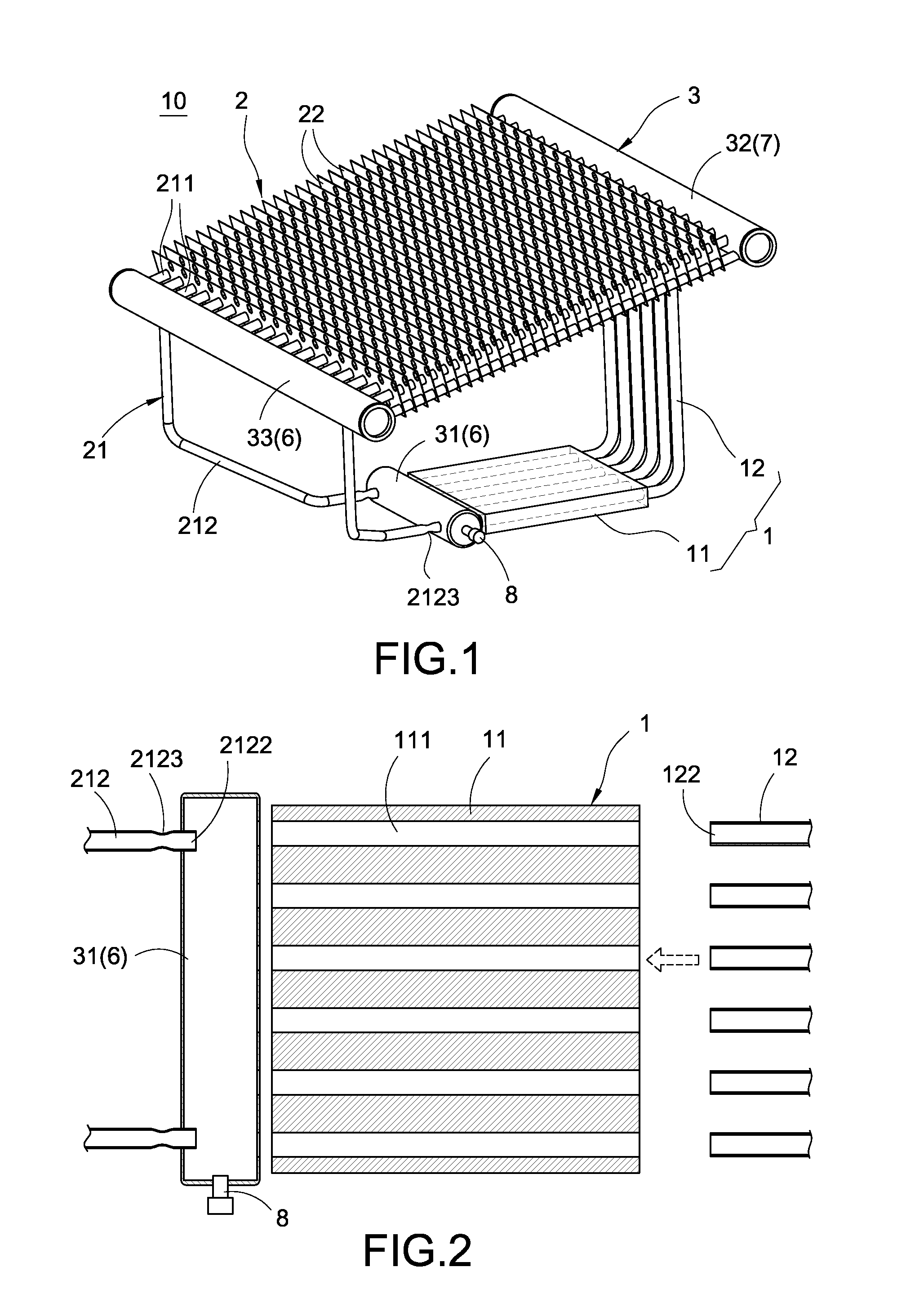

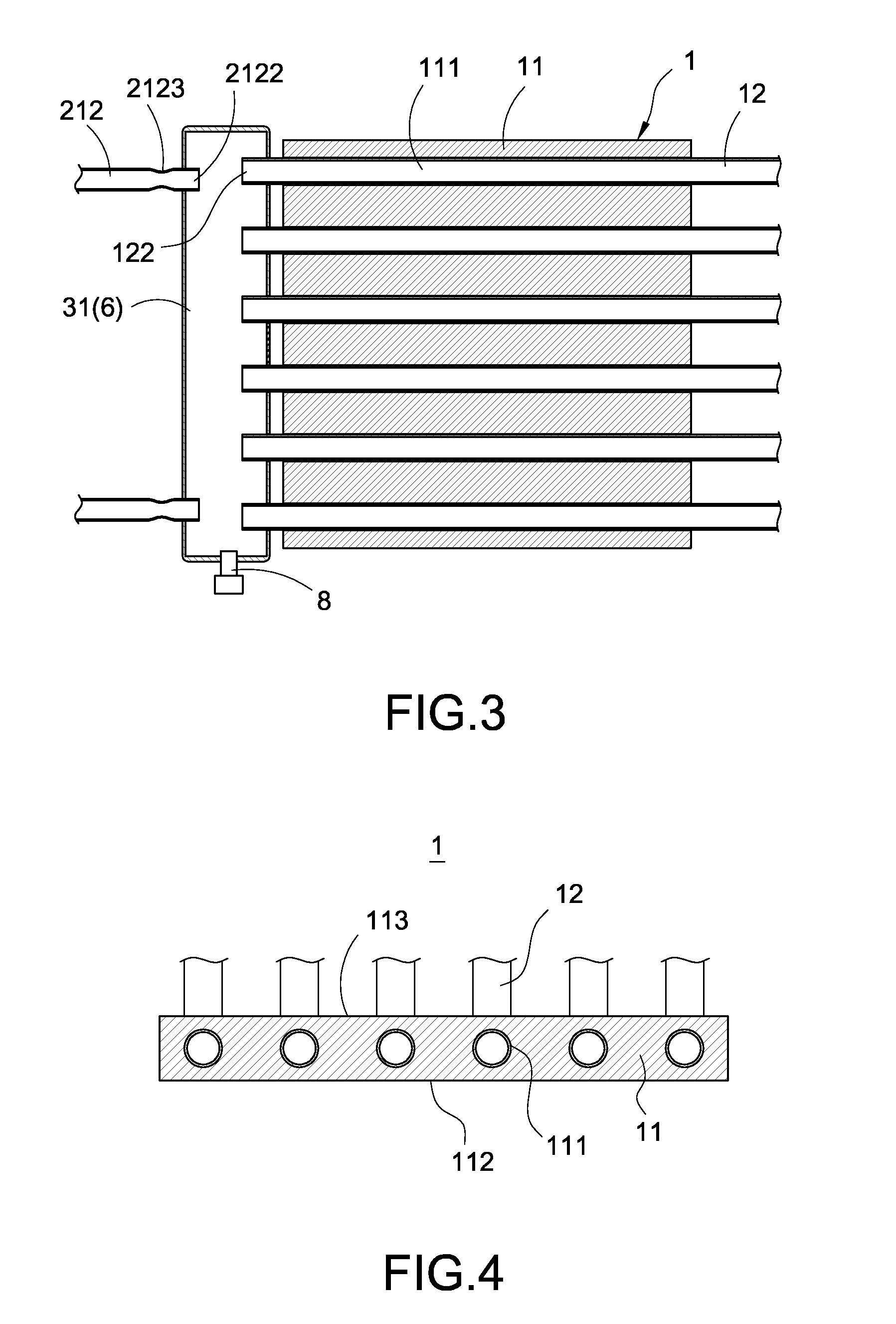

[0030]With reference to FIGS. 1 to 7 for a loop thermosyphon cooling device of the present invention, the thermosyphon cooling device 10 comprises an evaporator 1, a condenser 2 and a communication assembly 3.

[0031]The evaporator 1 includes a heat conducting element 11 and plurality of evaporation pipes 12, and both ends of each evaporation pipe 12 have a liquid inlet end 122 and a gas outlet end 123 respectively. With reference to FIGS. 1 to 4 for a heat conducting element 11 of the first preferred embodiment of the present invention, the heat conducting element 11 has a plurality of through holes 111, and each evaporation pipe 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com