All-foam mattress assemblies with foam engineered cores having thermoplastic and thermoset materials, and related assemblies and methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

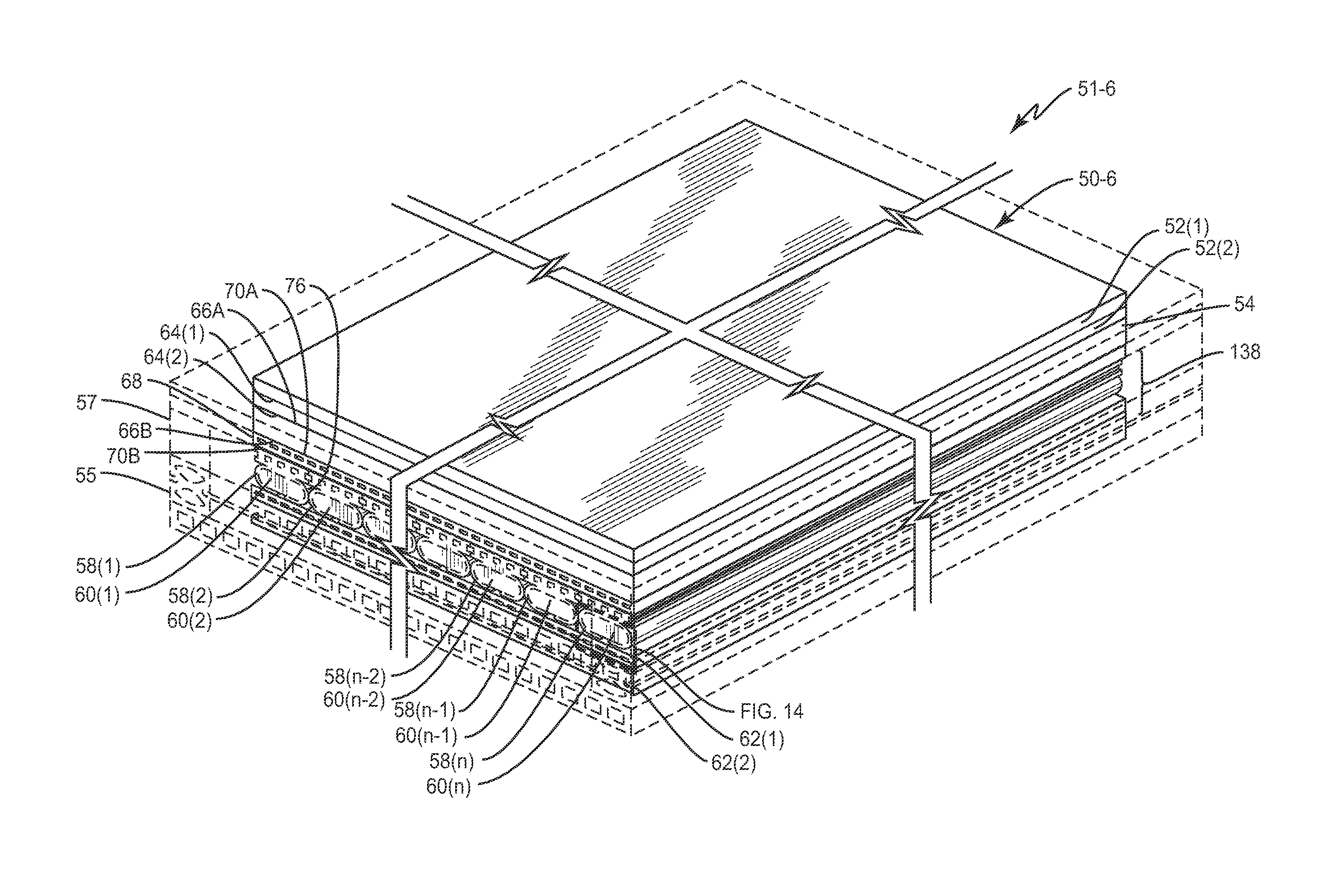

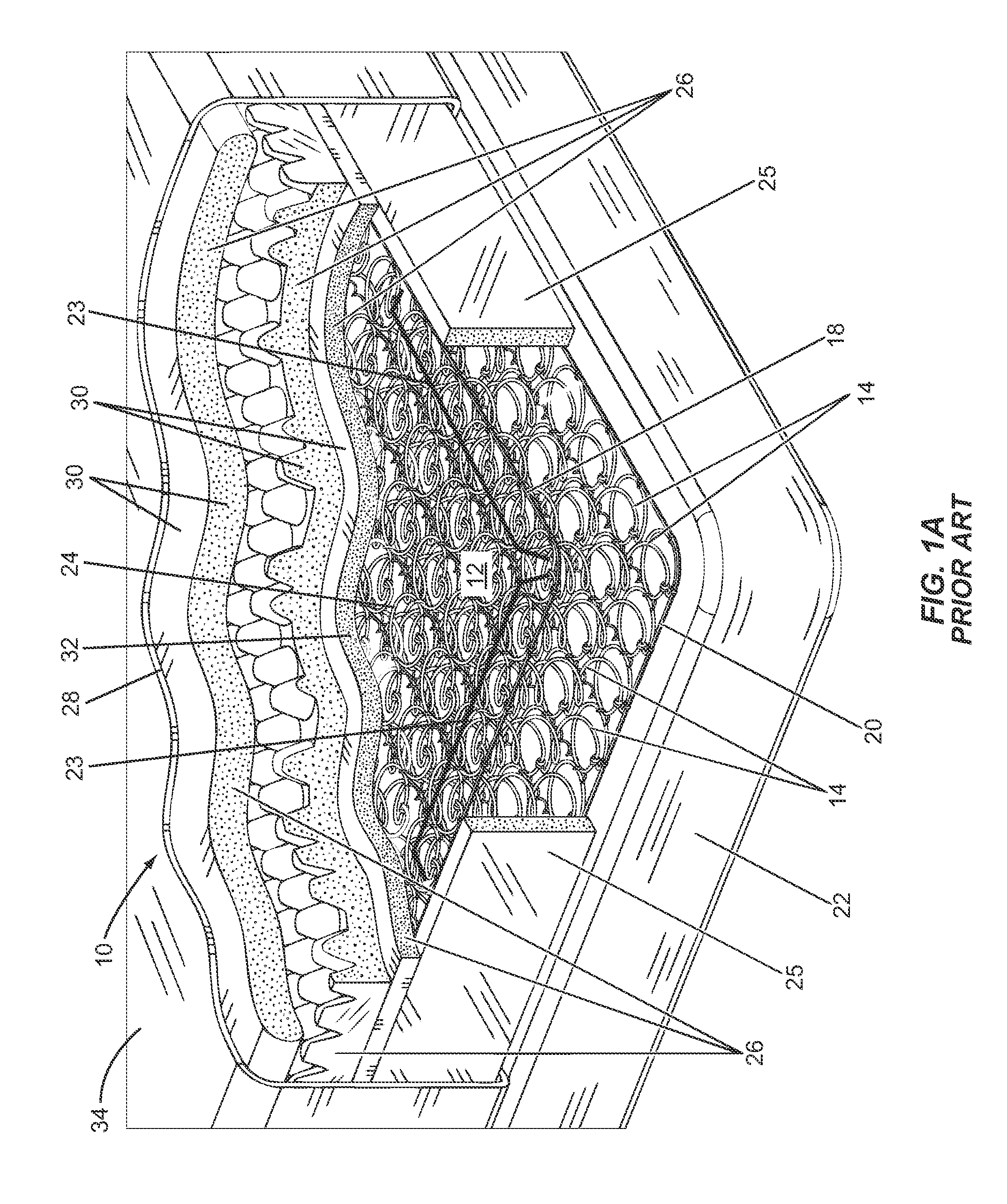

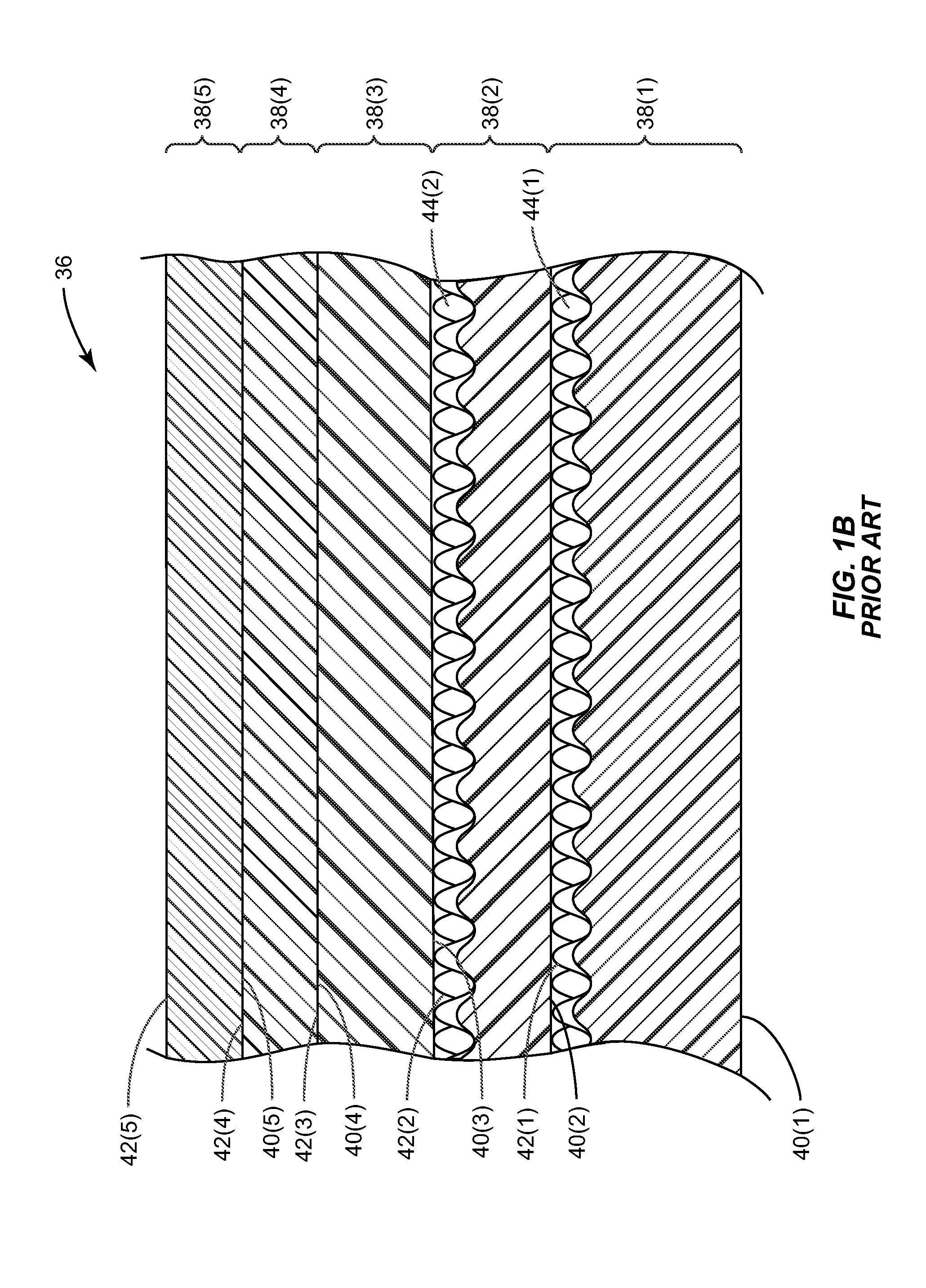

[0017]Embodiments disclosed herein include all-foam mattress assemblies with foam engineered cores having thermoplastic and thermoset materials, and related assemblies and methods. All-foam mattress assemblies use foam-based materials, such as thermoplastic and thermoset, to provide cushioning and support characteristics for a user in the sleeping area of a mattress during sleep or rest. The all-foam mattress assemblies may include foam comfort layer(s), foam transitional layer(s), and a foam engineered core. The all-foam engineered core may lessen a density of a mattress assembly by comprising thermoset member(s), and engineered geometric thermoplastic material profile(s) adjacent to the thermoset member(s). The engineered geometric thermoplastic material profile(s) may be disposed in a parallel or substantially parallel arrangement. In this manner, the all-foam engineering core may provide cushioning and support characteristics with reduced density compared to a foam mattress prov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap