Slideboard

a technology of sliding board and sidewall, which is applied in the field of sliding board, can solve the problems of skis being subjected to particularly heavy wear and tear, skis being delaminated or spalling etc., and achieve the effect of increasing the strength of the joint between the sidewall and the upper reinforcement plies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

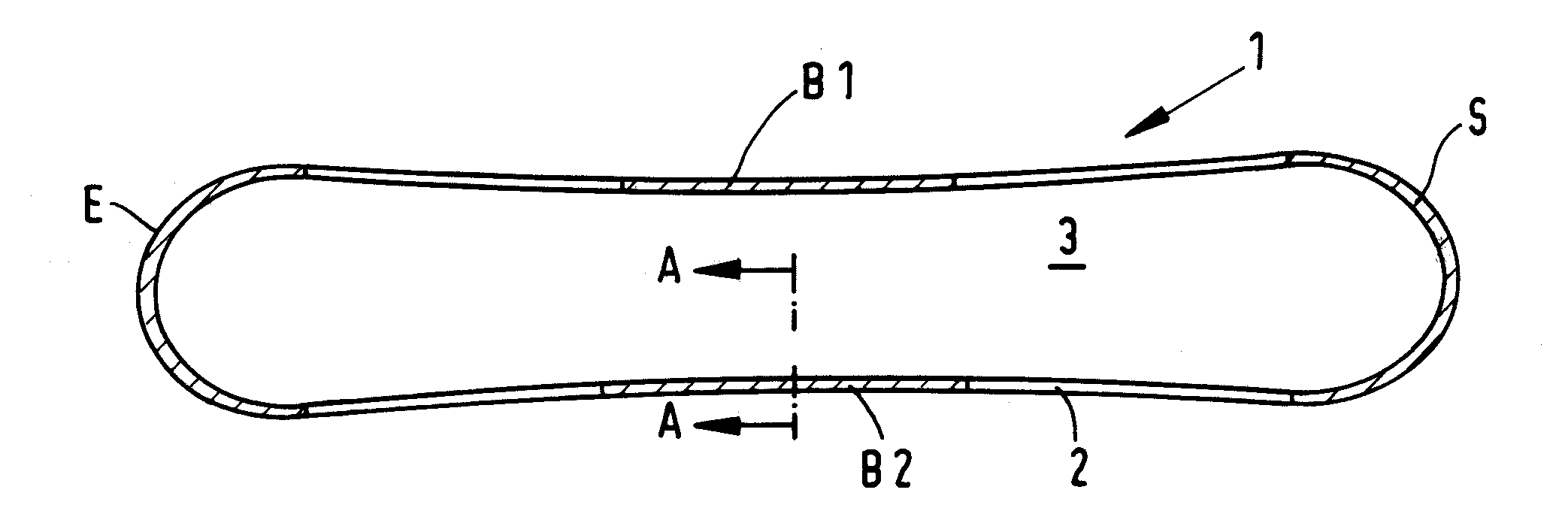

[0025]According to FIG. 1, the slideboard 1 has a sidewall 2 extending around the entire circumference of the slideboard (snowboard), with the sidewall 2 surrounding the top sheet 3 in the top view according to FIG. 1.

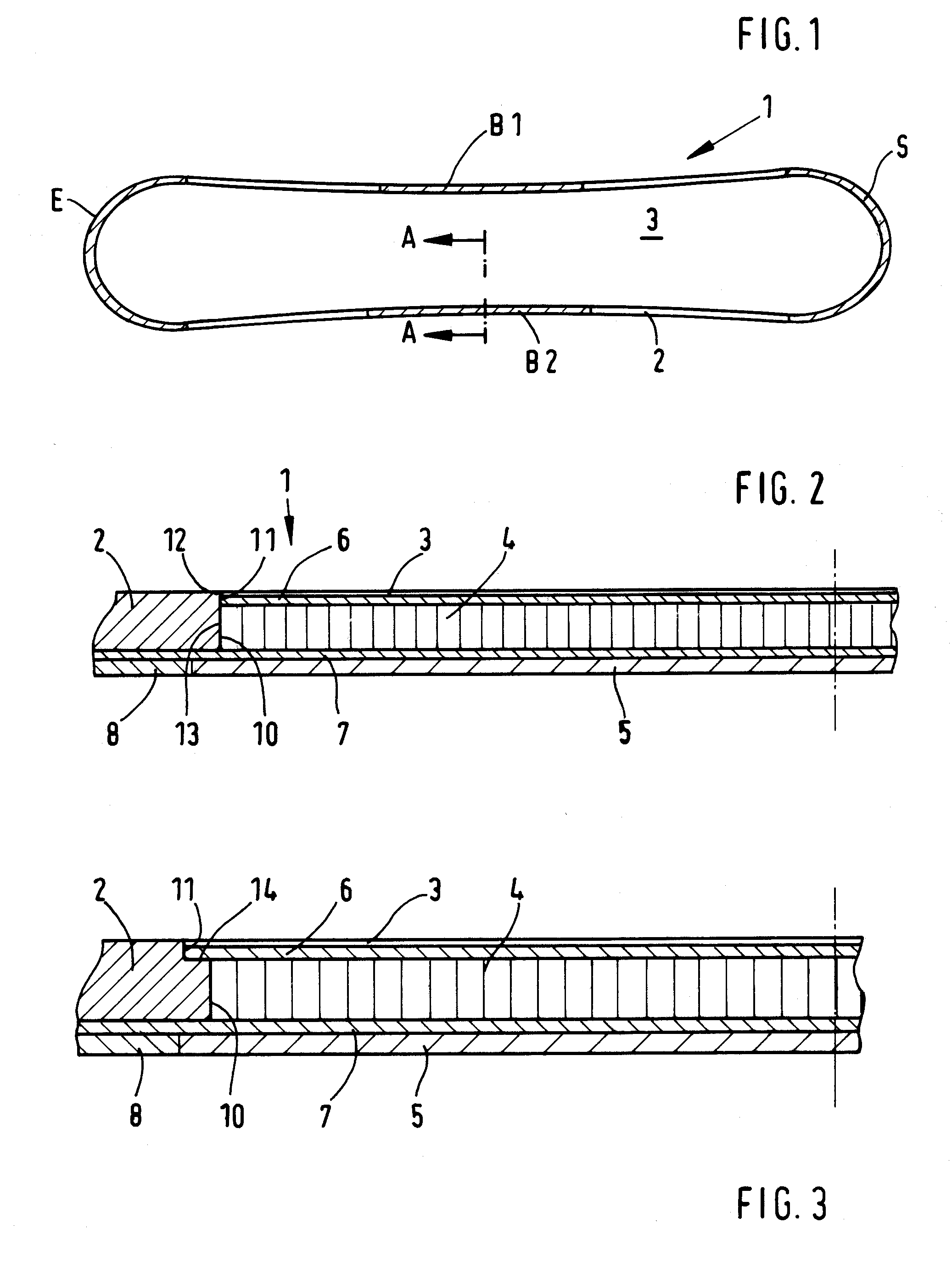

[0026]According to FIG. 2, the snowboard has, in addition to the sidewall 2 and the top sheet 3, a core 4 which is made, for example, of laminated wood, a base 5 as well as upper reinforcement plies 6 on the upper side of the core 4 and lower reinforcement plies 7 between the core 4 and the sidewall 2 as well as the base 5, with the base 5 being surrounded by a steel edge 8.

[0027]Whereas, according to FIGS. 2 and 3, the lower reinforcement plies 7 extend below the sidewall 2 to the outer side of the slideboard 1, the sidewall 2 laterally covers with its inner side 13 both the core 4 and the upper reinforcement plies 6, including the top sheet 3.

[0028]According to FIG. 2, the lateral surface 10 of the core 4, the lateral surface 11 of the upper reinforcement plies 6 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com