Closure Arrangement for Cans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

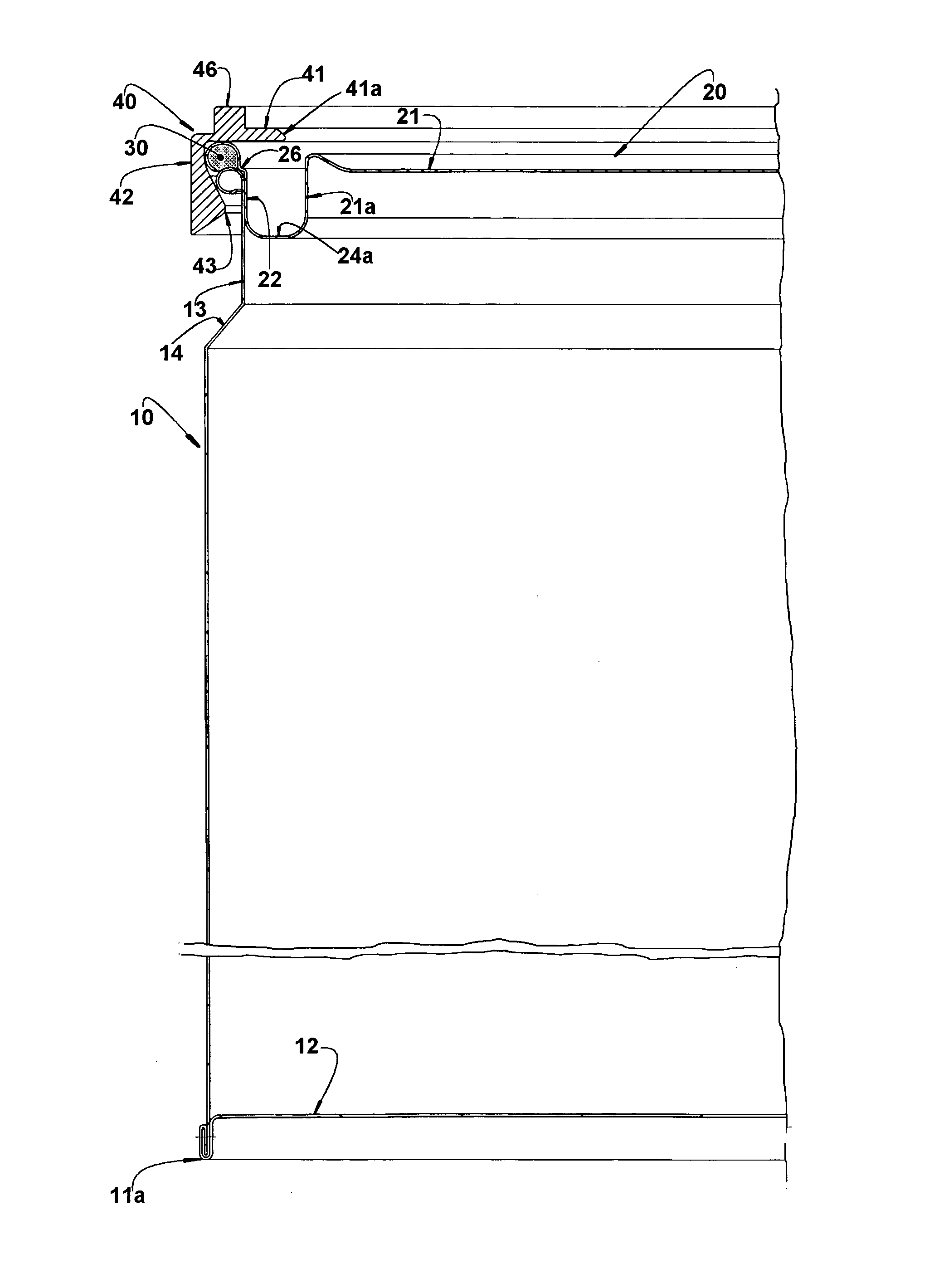

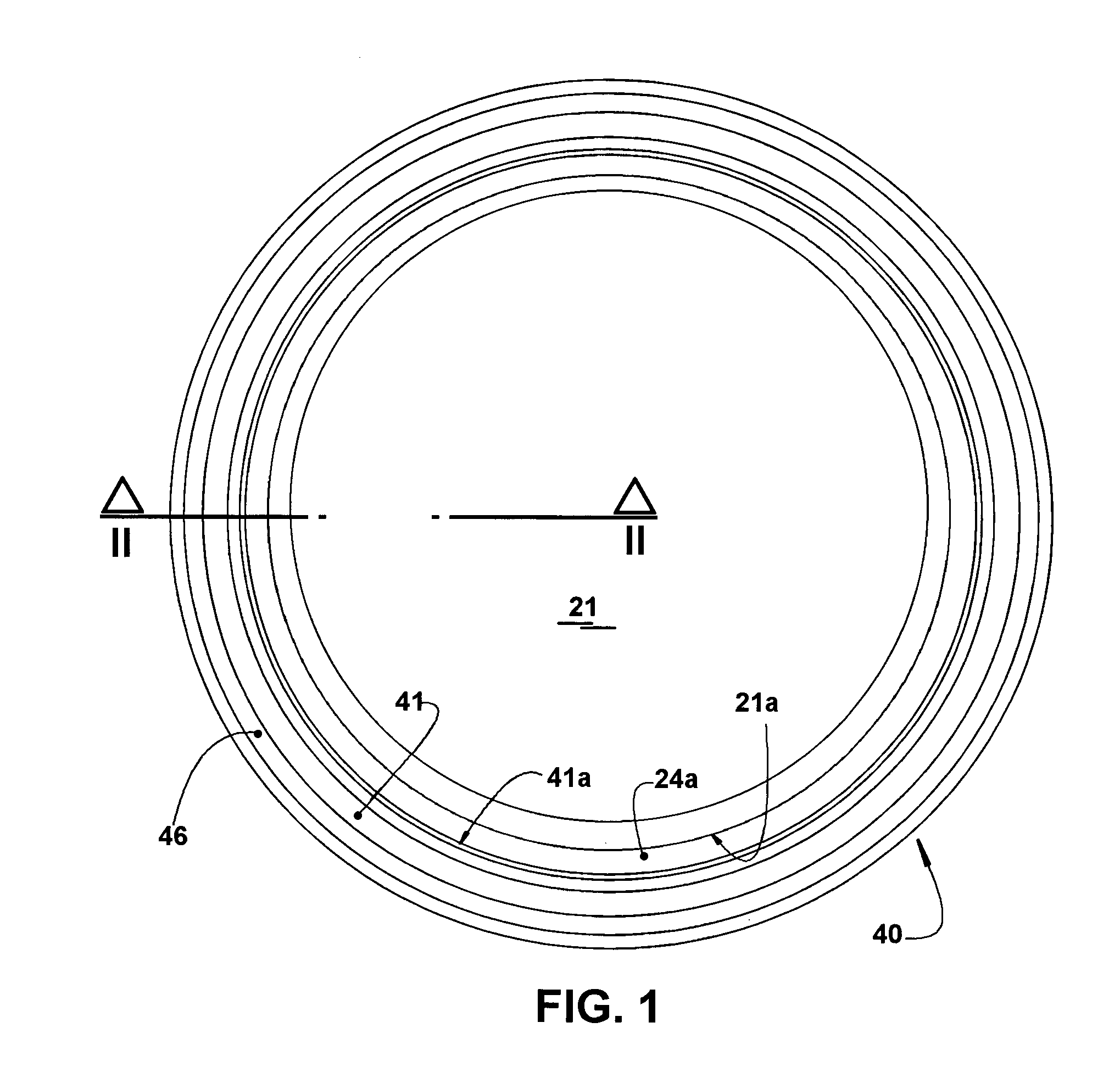

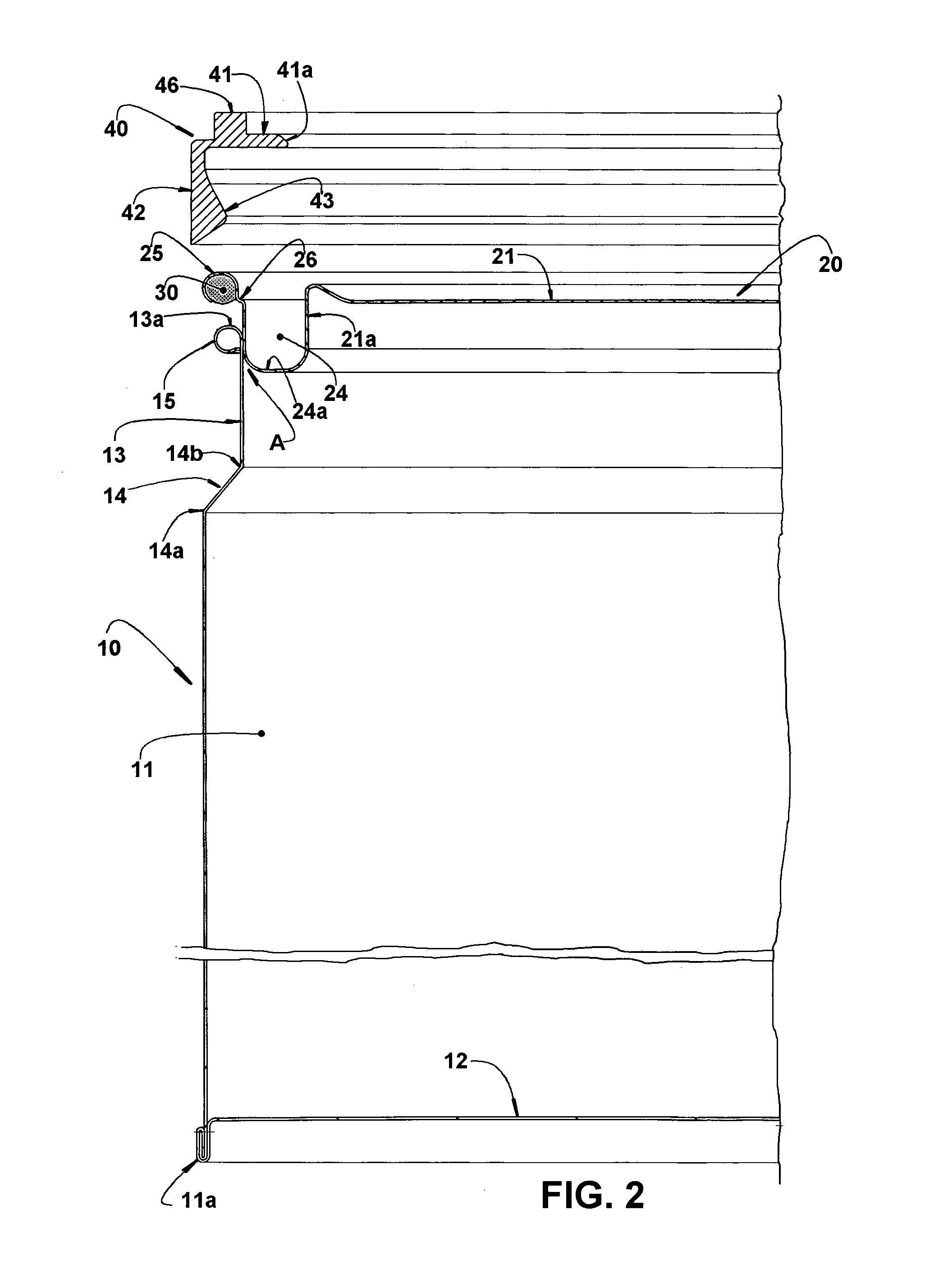

[0024]As already previously described and illustrated in the enclosed drawings, the closure arrangement proposed by the invention is applied to a can 10 formed in metallic sheet, generally tinplate, presenting a generally circular cross-section, but which can be polygonal, although not being illustrated in the drawings.

[0025]The tubular shaped can 10 comprises: a body portion 11, in whose lower end edge 11a is affixed, generally by double-seaming, the peripheral edge of a bottom wall 12; a neck portion 13 having a concentric contour, which is similar and reduced in relation to that of the body portion 11, and an upper end edge 13a defining the contour of an upper opening A for the can 10; and a transition portion 14 with a profile inclined in relation to the axis of the can 10 and joining the body portion 11 and the neck portion 13.

[0026]The upper end edge 13a of the neck portion 13 incorporates an outer peripheral projection 15. In the illustrated condition, the outer peripheral pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com