Architecturally finished complete building envelope system

a complete building and architectural technology, applied in the field of architecturally finished complete building envelope systems, can solve the problems that the material demand of required earth's resources to construct conventional habitats will outstrip the supply, and achieve the effects of reducing construction costs, saving time and labor, and avoiding several time-consuming and costly steps in the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

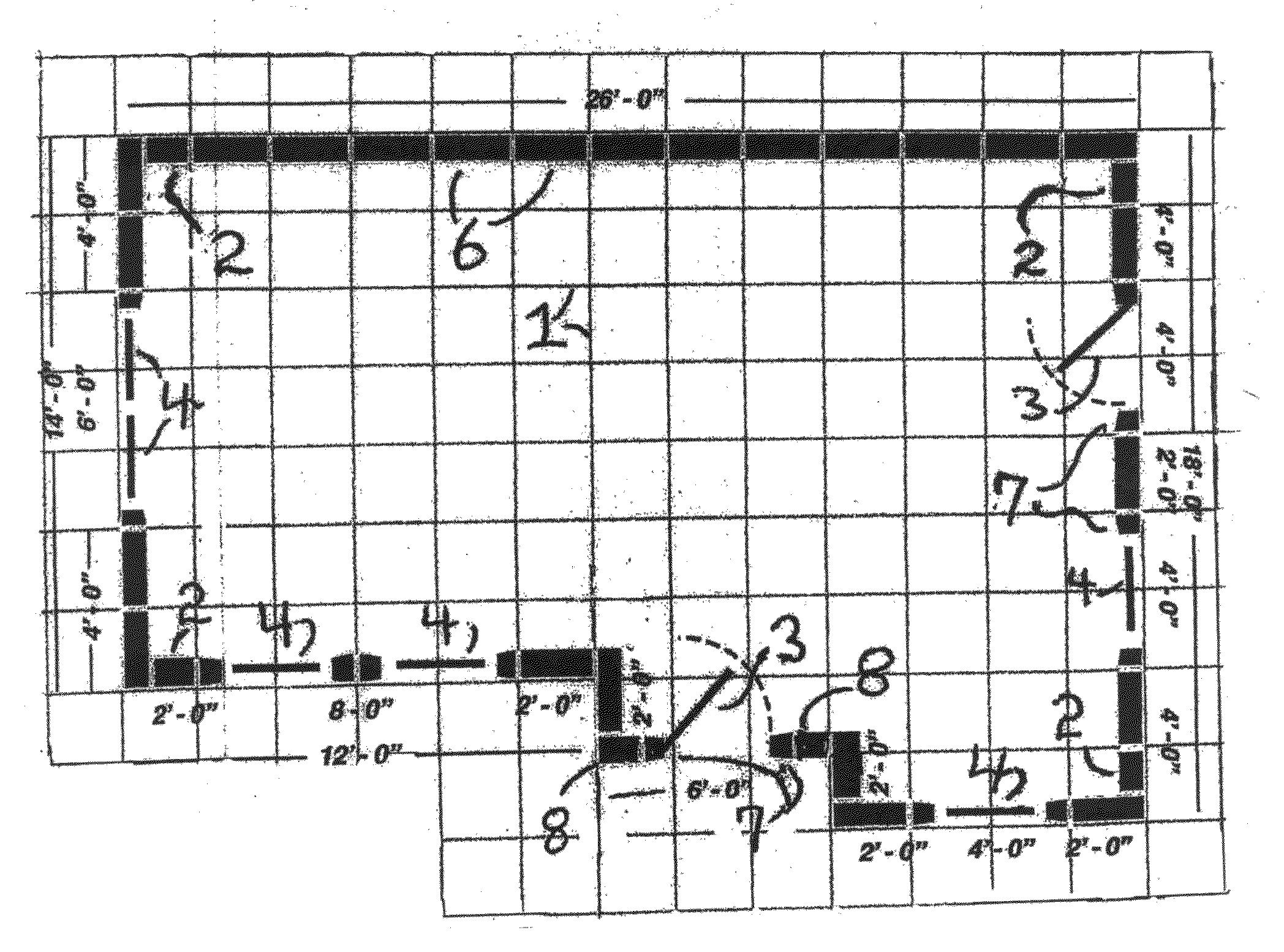

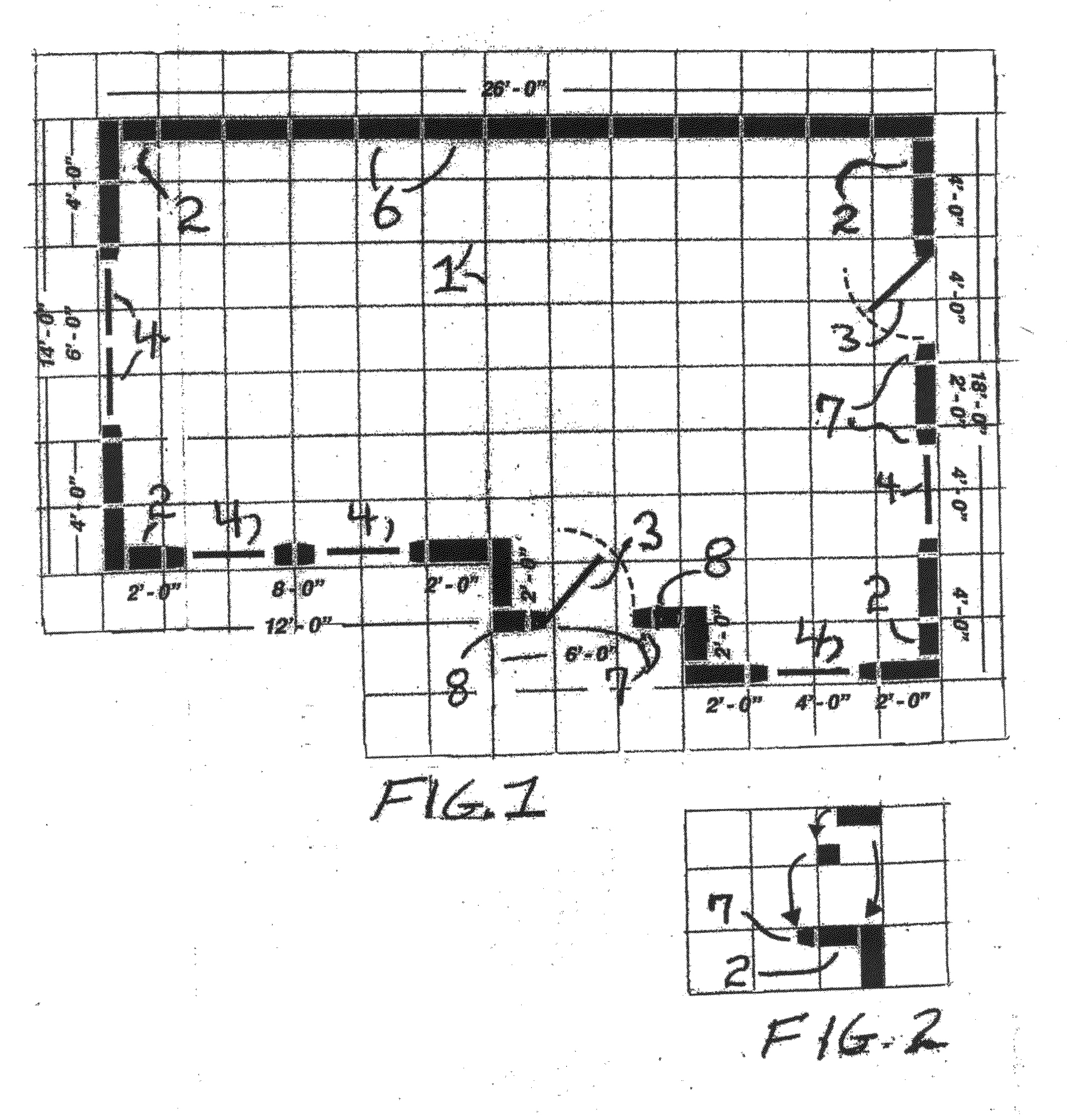

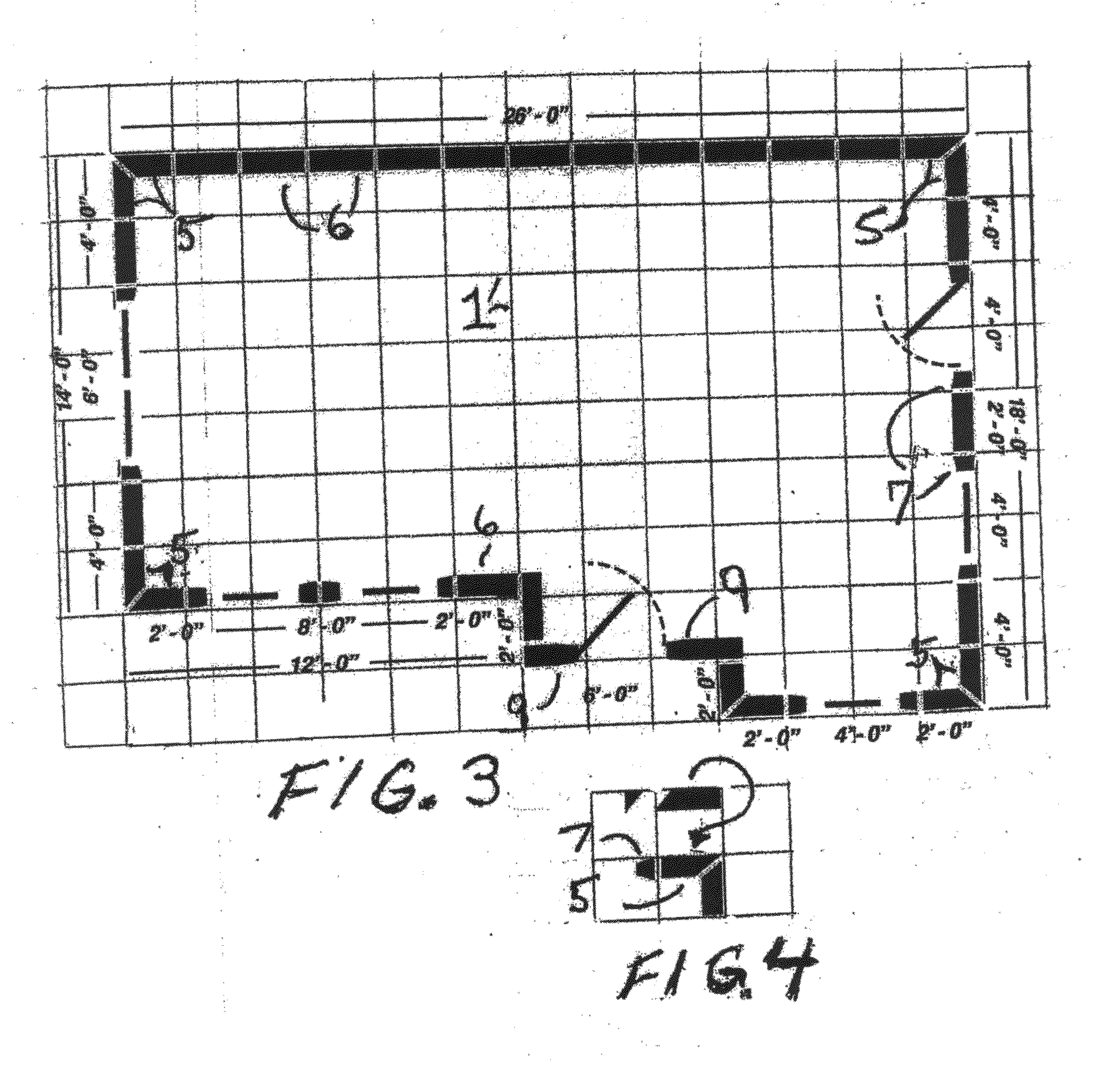

[0057]FIG. 1 teaches the floor plan layout linear grid units 1 coordinated with filler block 2 components of the Computerized Grid System software program. The number of linear grid units 1 is the basis and over all factoring by calculating the number of grid units 1, whether horizontal or vertical, then multiplying the number of grid units by various components of the known teaching of a self-leveling base panel that has utility chase and contains only enough reinforcing to transport and install, the 6′ tall wall block, the header top panel that has continuous reinforcing sufficient to act as header for openings and the air duct system then subtracting the CGS grid area units 1 of the number and type of openings (door 3, window 4, etc.). This makes it is possible to accurately estimate the total number and type of components, labor time for construction, etc. of an entire structure including roof of FIG. 5B. The roofing component of tis application's teaching of invention CGS syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical-resistant | aaaaa | aaaaa |

| vapor permeability | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com