Floating manhole frame assembly

a manhole frame and assembly technology, applied in the direction of artificial islands, construction, building components, etc., can solve the problems of unbalanced movement of the surrounding structure, uneven surface, and many conventional manhole frame assemblies that cannot move in harmony with the ground or the surrounding structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

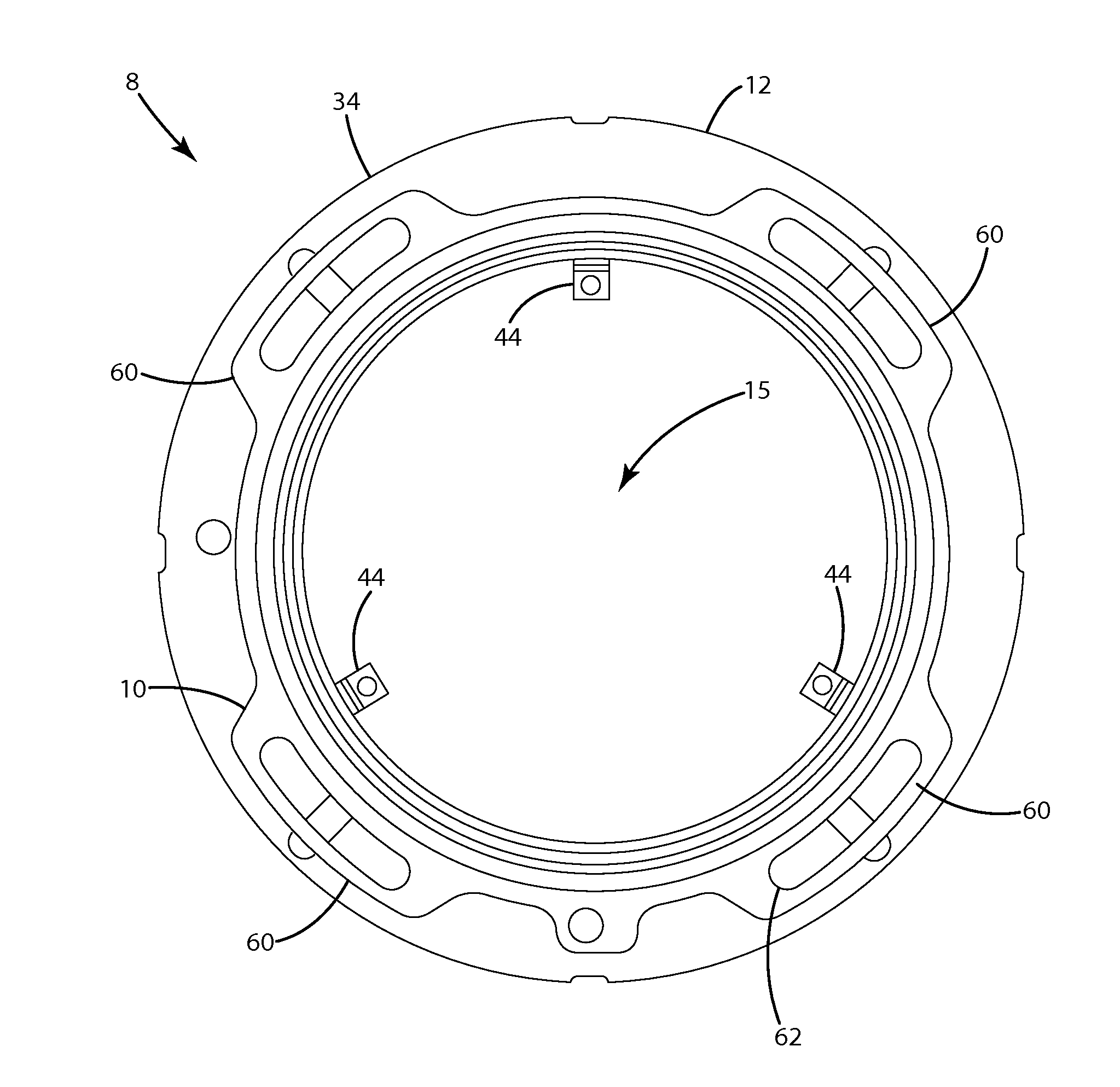

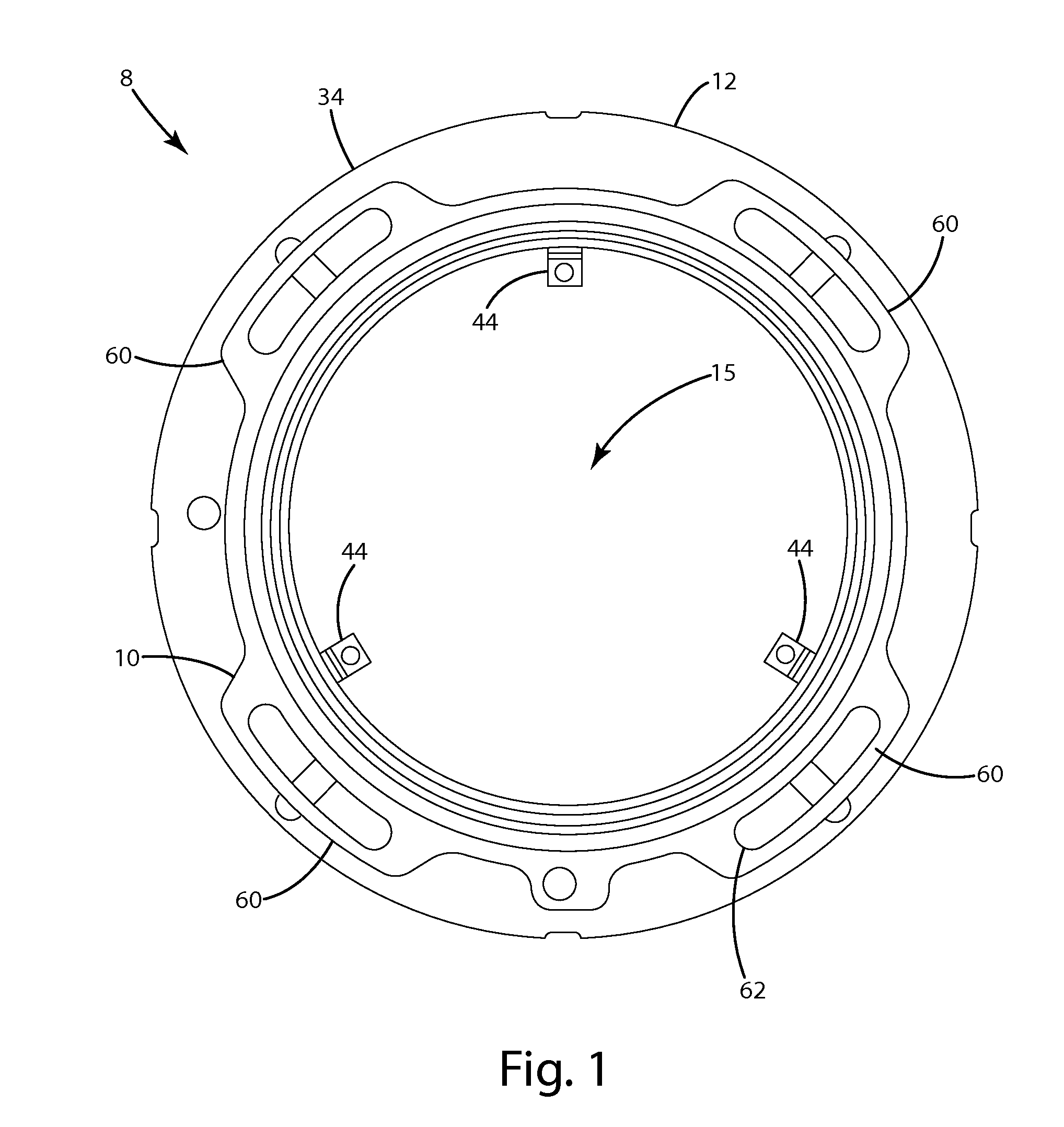

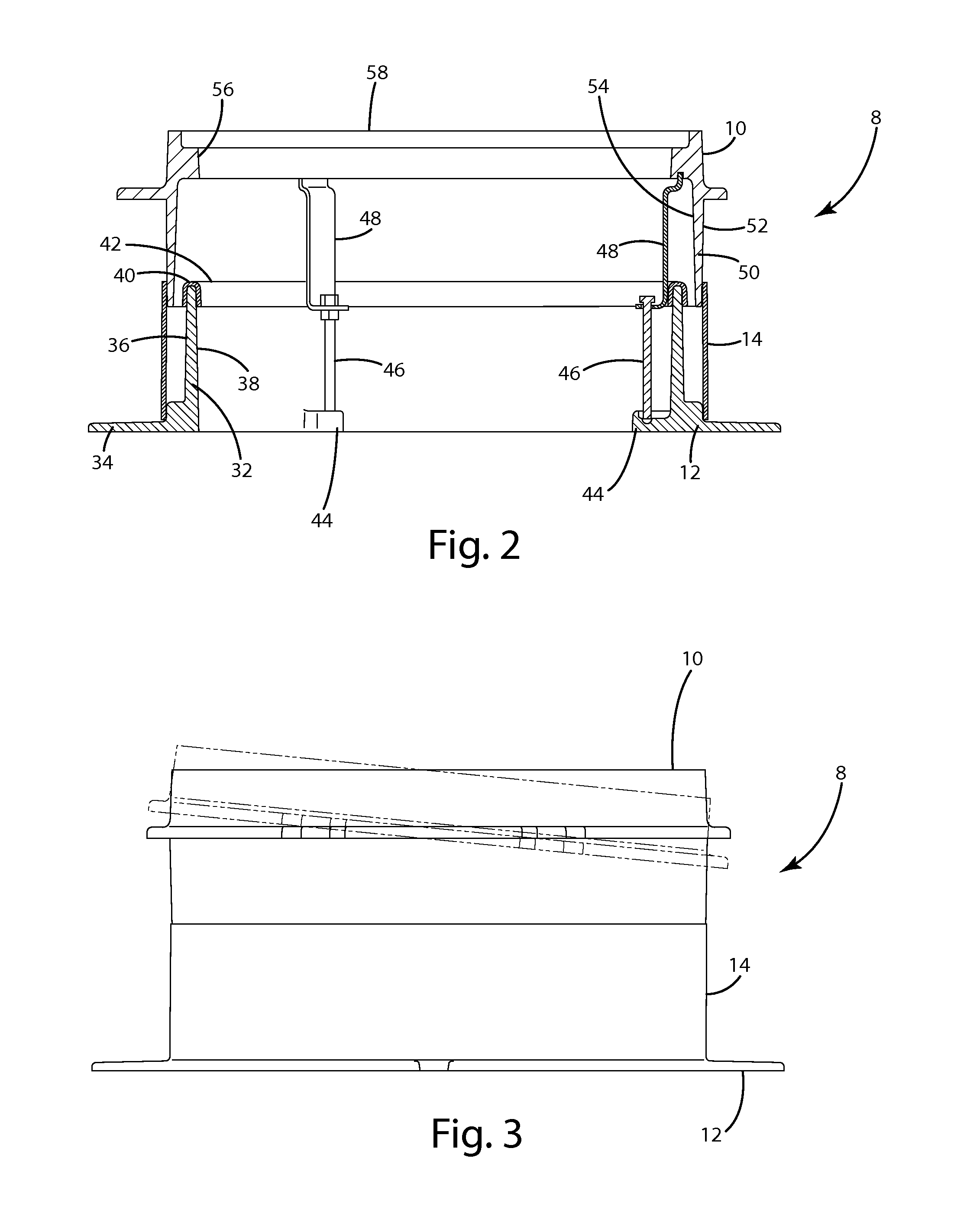

[0018]A manhole frame assembly according to one embodiment of the present invention is shown in FIGS. 1-6 and generally designated 8. The manhole frame assembly 8 generally includes an upper frame 10 and a lower frame 12, and is adapted to support a manhole cover (not shown). The upper frame 10 in the current embodiment is allowed to float with respect to the lower frame 12, enabling the upper frame 10 to move with respect to the lower frame 12 during installation or as the surrounding structure moves, and potentially preventing uneven transitions between the manhole frame assembly and the surface of the surrounding structure. The manhole frame assembly 8 also includes a sleeve 14 disposed around the perimeter of the upper frame 10 and the lower frame 12. This sleeve 14 may shield portions of the upper frame 10 and the lower frame 12 from the surrounding structure so that the surrounding structure does not significantly impede movement of the upper frame 10 with respect to the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com