Connector Device for a Telescoping Tent Pole

a technology of connecting device and tent pole, which is applied in the direction of rod connection, building type, construction, etc., can solve the problems of difficult and cumbersome repair, time-consuming factory assembly, and high cost of connecting assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

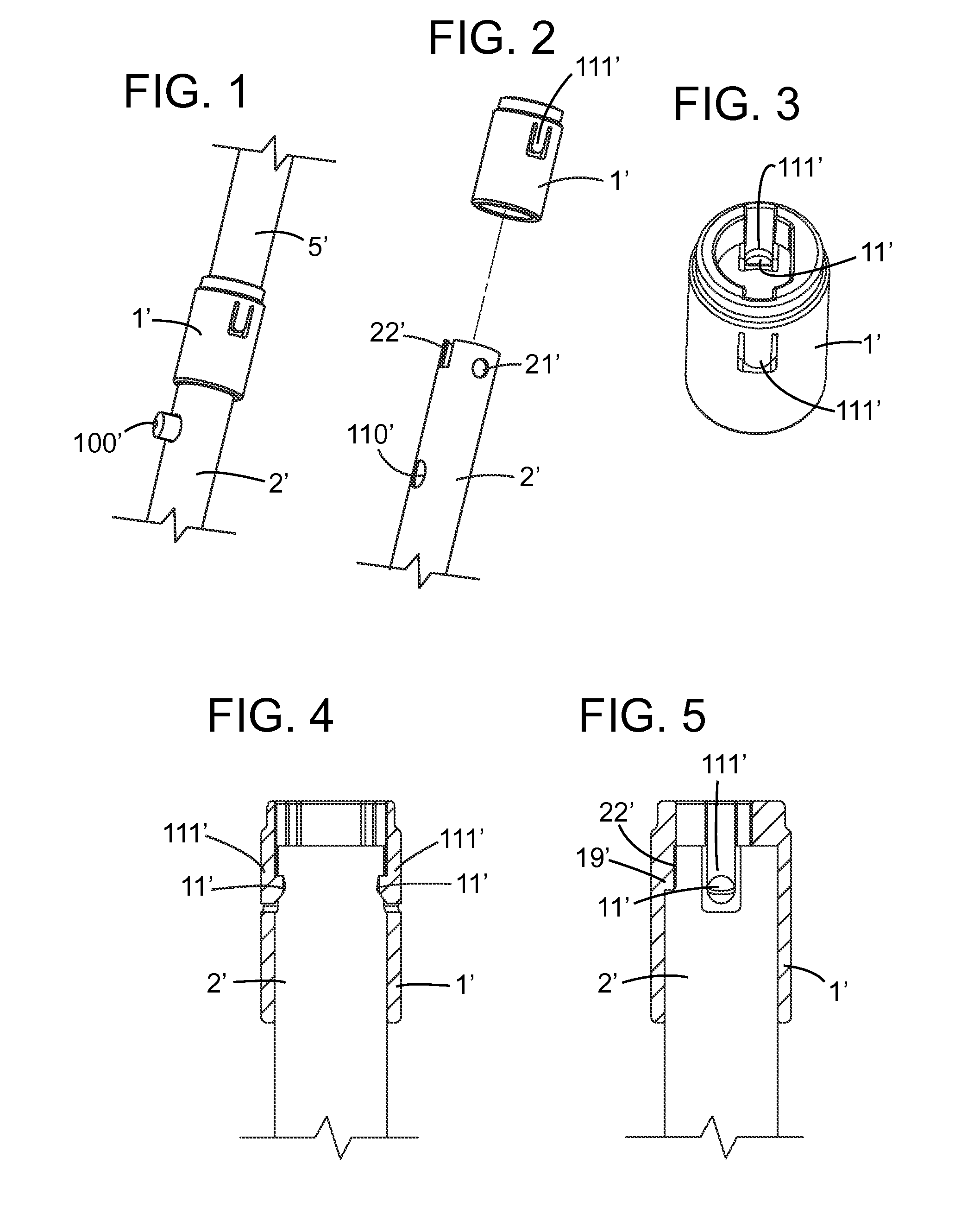

[0035]Referring to FIGS. 1-8, a connector device 1′ for a telescoping tent pole in the present invention is shown, in which the connector device 1′ includes a tubular member having an interior with an interior surface having at least one detent 11′ and a lower aperture for receiving a lower pole 2′ into the interior. A top member on the tubular member has an upper aperture for receiving an upper pole 5′ into the interior of the tubular member. The connector device 1′ is preferably manufactured by plastic injection molding and is one integral piece.

[0036]In the present embodiment, the lower pole 2′ is tubular steel having a circular cross-section and the upper pole 5′ is tubular steel having a generally semi-circular cross-section. The upper pole 5′ is sized such that it telescopes within the lower pole 2′, and the upper and lower apertures of the connector device 1′ are respectively sized and shaped for the same. One of ordinary skill in the art will recognize that the upper and low...

second embodiment

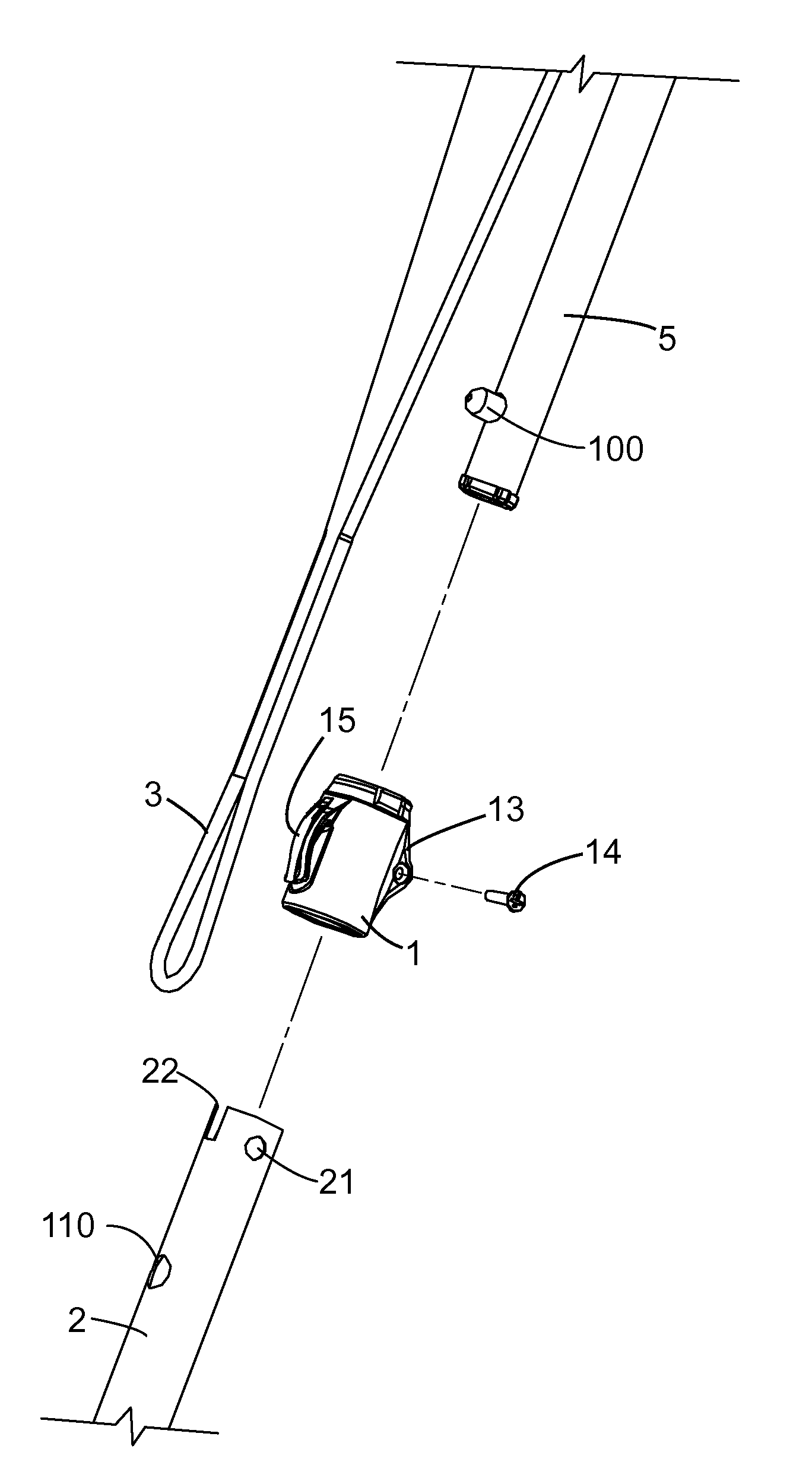

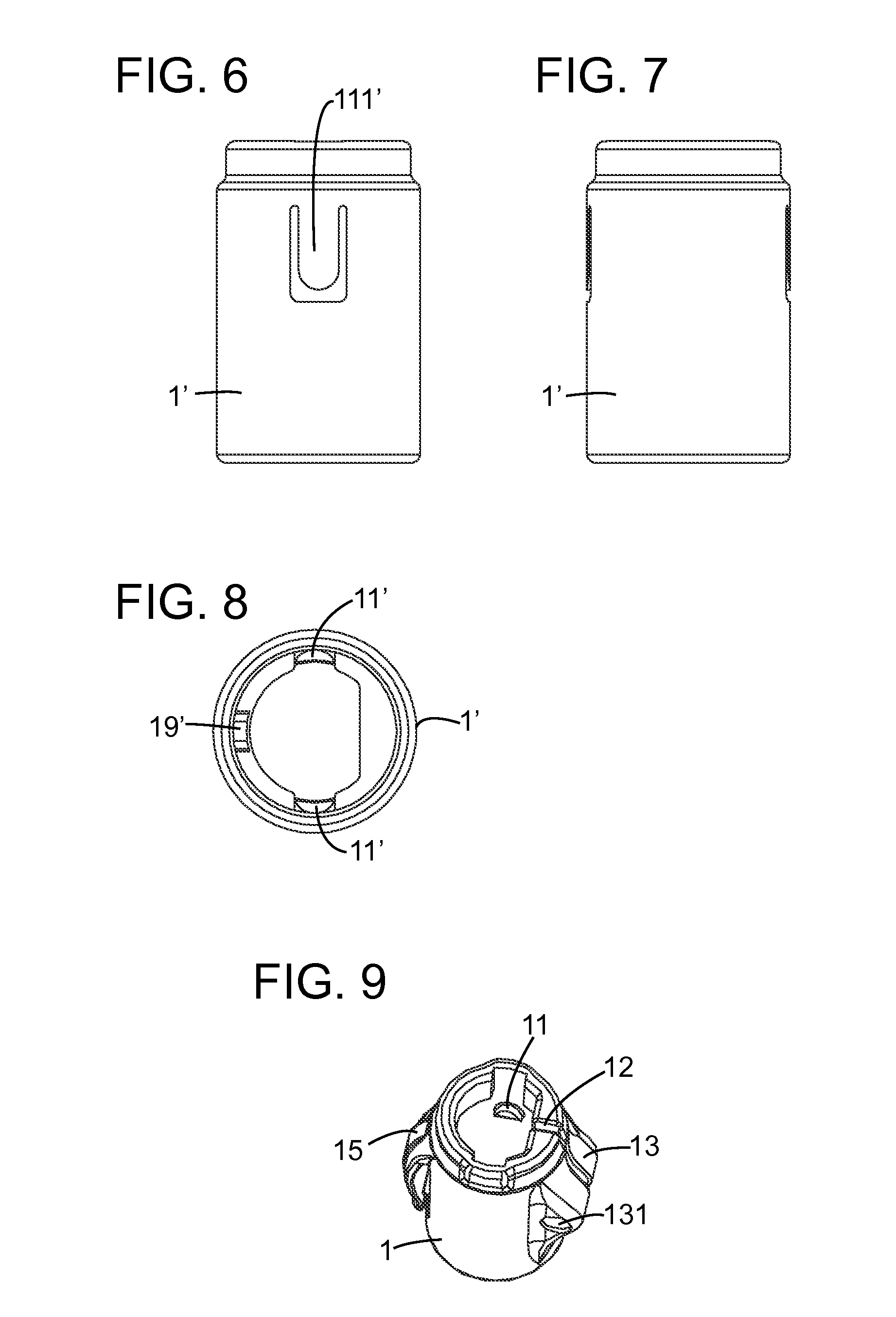

[0041]Referring to FIGS. 9-14, in the present invention, a connector device 1 for connecting a telescoping tent pole as well as for securing a tent fly 3 is shown. The connector device 1 is preferably constructed by injection molding plastic into one integral component. The interior of the connector device 1 has an interior surface having a pair of detents 11 extending laterally therefrom; a lower aperture for receiving a lower pole 2 into the interior; and a top member on the tubular member has an upper aperture for receiving an upper pole 5 into the interior of the tubular member. A longitudinal axis extends through the upper and lower apertures of the tubular member substantially parallel to the interior of the connector device 1. Also, the configuration of the upper and lower poles 5, 2 are substantially identical to the upper and lower poles 5′, 2′ described above.

[0042]Still referring to FIGS. 9-14, an outer surface of the connector device 1 includes a tent fly fastener 15 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com