System and method for heavy equipment navigation and working edge positioning using an image acquisition device that provides distance information

a technology of distance information and image acquisition device, which is applied in the direction of vehicle position/course/altitude control, process and machine control, instruments, etc., can solve the problems of affecting the alignment and/or calibration of the delicate sensor mounted on the working edge, increasing the chance of damage, and affecting the accuracy of the positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Heavy Equipment and Working Edges

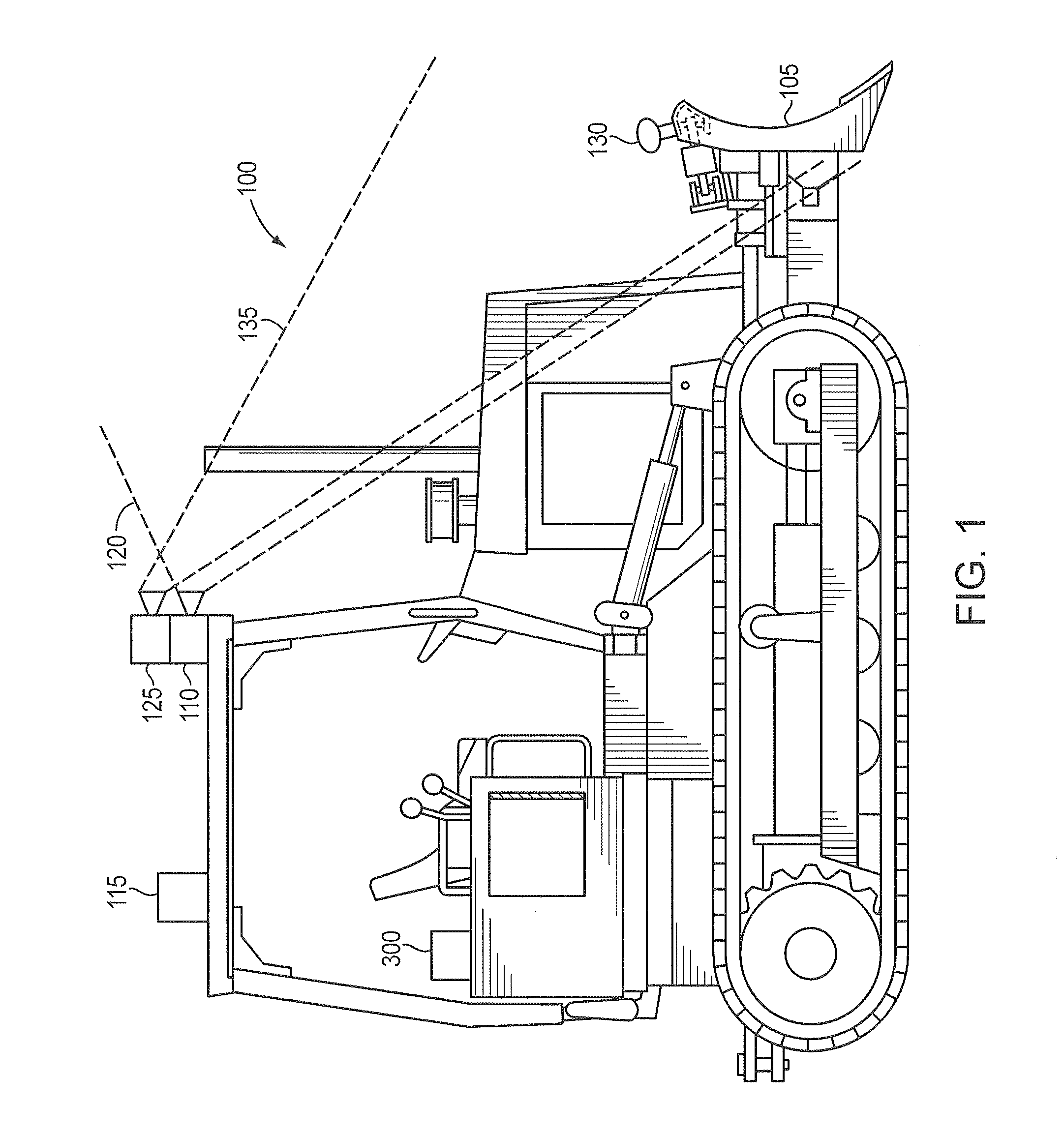

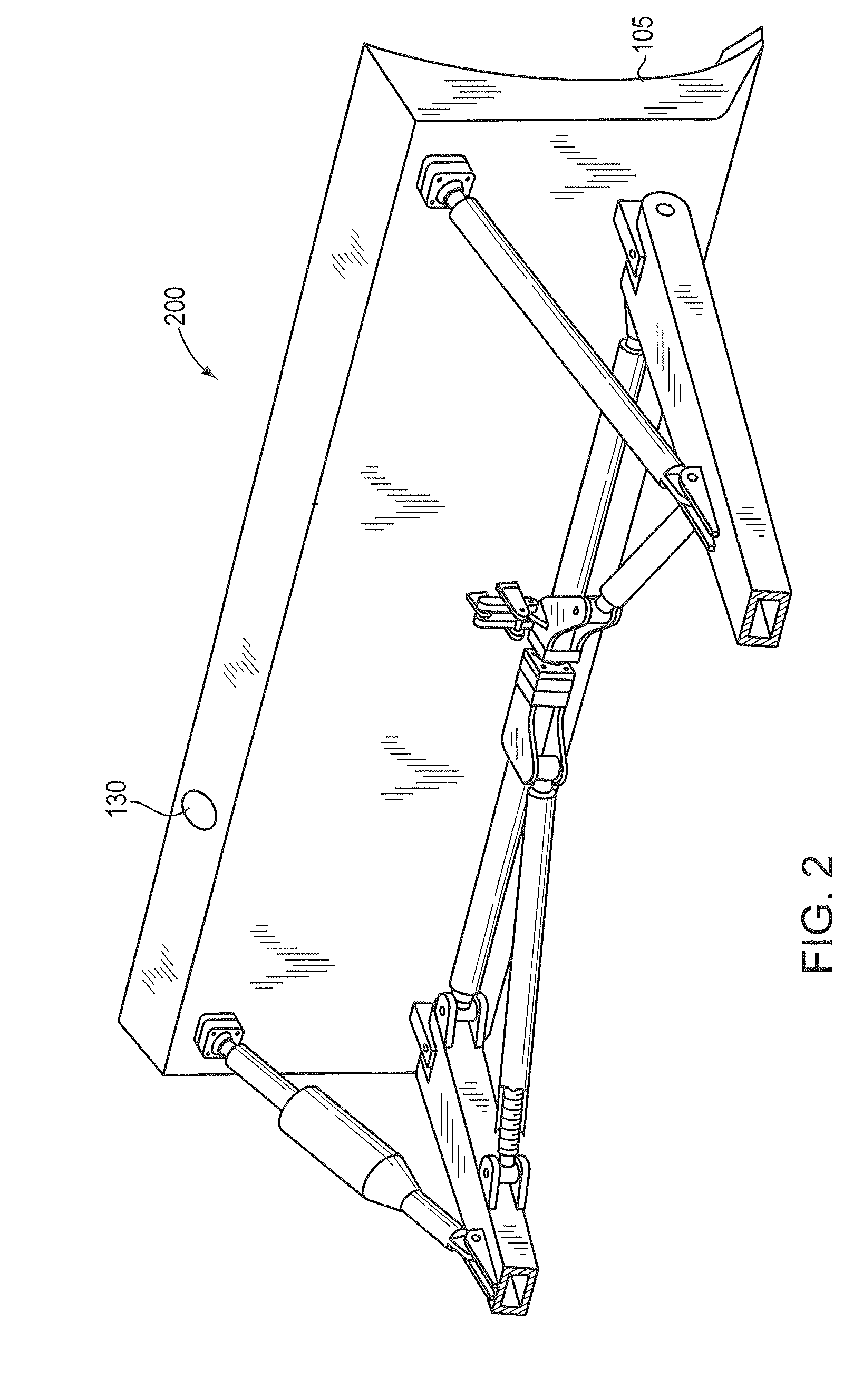

[0021]FIG. 1 is a side view of an exemplary heavy equipment vehicle 100, e.g., a bulldozer, in which the principles of the present invention may be utilized in accordance with an illustrative embodiment of the present invention. The bulldozer 100 illustratively comprises a working edge, e.g., blade 105. Further, the bulldozer 100 includes an image acquisition device 110 mounted thereon that is configured to obtain images of a target 200 that is operatively interconnected / affixed to the blade 105. The image acquisition device 110 includes a fixed field of view 120 that includes the spatial region within which the target 200 may move during operation of the working edge 105. Illustratively, the image acquisition device 110 comprises a time of flight (TOF) camera. A TOF camera illustrative provides both an intensity value and a distance from the camera for each pixel in the TOF camera's field of view. Operatively interconnected with the image acquisitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com