Sole assembly for article of footwear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

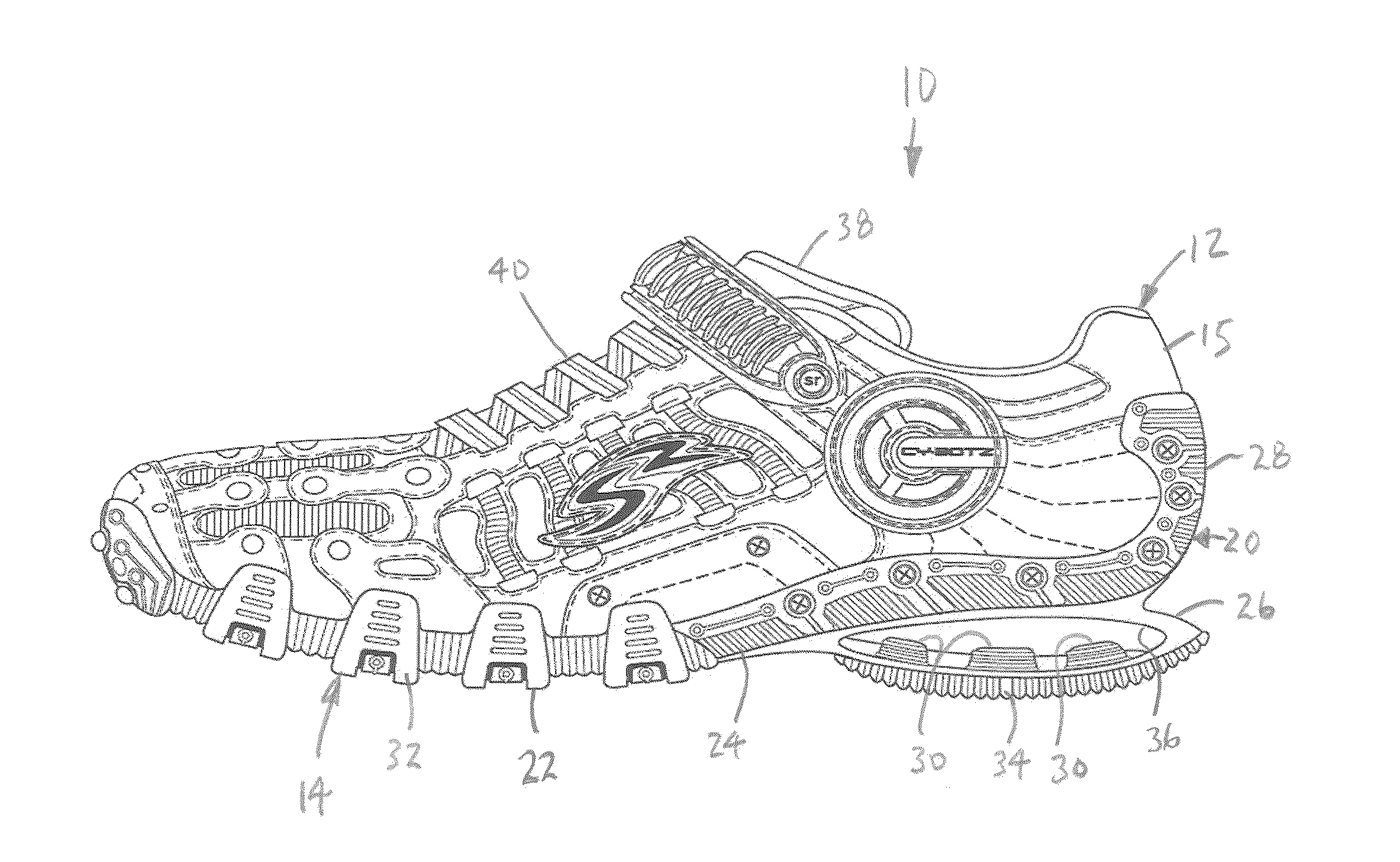

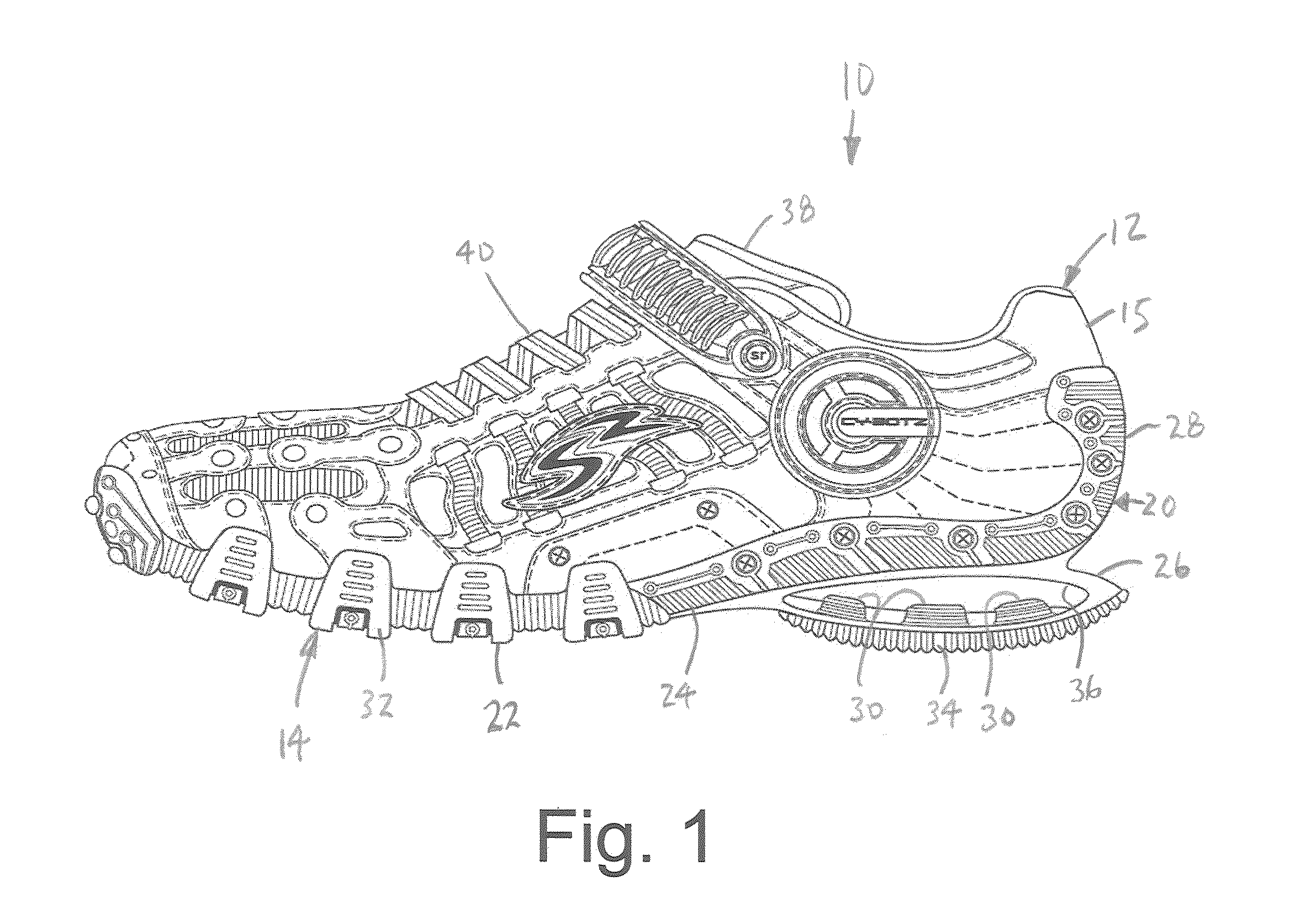

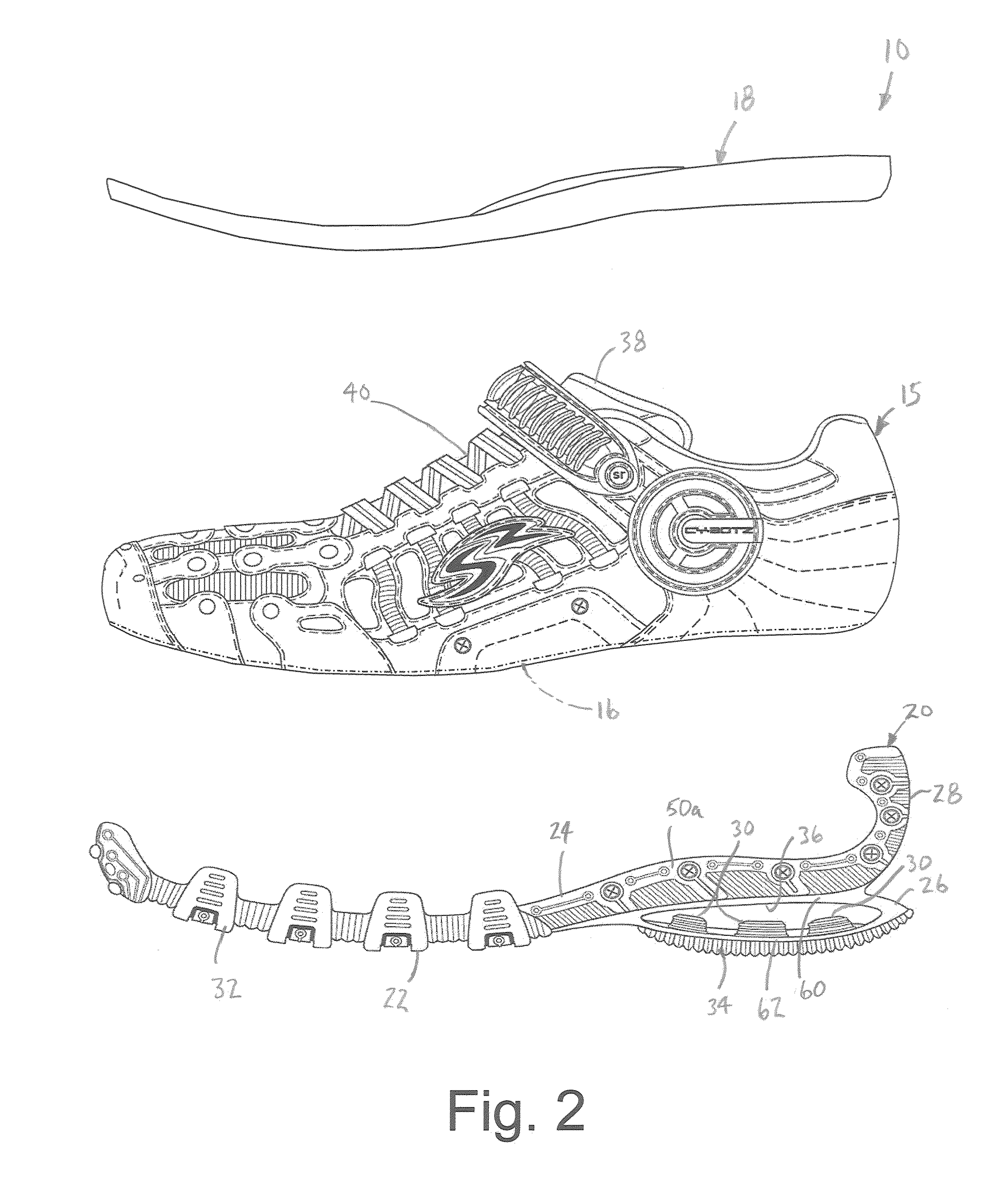

[0025]An article of footwear in accordance with an embodiment of the present invention is shown in FIGS. 1 and 2 and generally designated 10. The article of footwear 10 generally includes an upper assembly 12 and a sole assembly 14. In this embodiment, the upper assembly 12 is a generally conventional upper assembly utilizing a strobel construction in which a foot-receiving upper 15 is closed on the bottom by an insole board 16 or other similar component (See FIG. 2). In the illustrated embodiment, the sole assembly 14 generally includes a footbed 18, a sole component 20 and an outsole 22. The footbed 18 is fitted into the upper assembly 12 atop the insole board 16 to provide support and cushioning from inside the upper assembly 12. In this embodiment, the sole component 20 is of a single unitary construction and it generally includes a flex plate 24, a heel spring 26 and a heel cup 28. The heel spring 26 may be an elliptical spring that is disposed in the heel of the shoe 10 genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com