Hook and Loop Fastener Doffing System

a technology of doffing system, which is applied in the field of garments, can solve the problems of peeling apart the assembly of the hook and loop fastener, and achieve the effects of easy separation, easy connection of portions of the garment, and resistance to separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

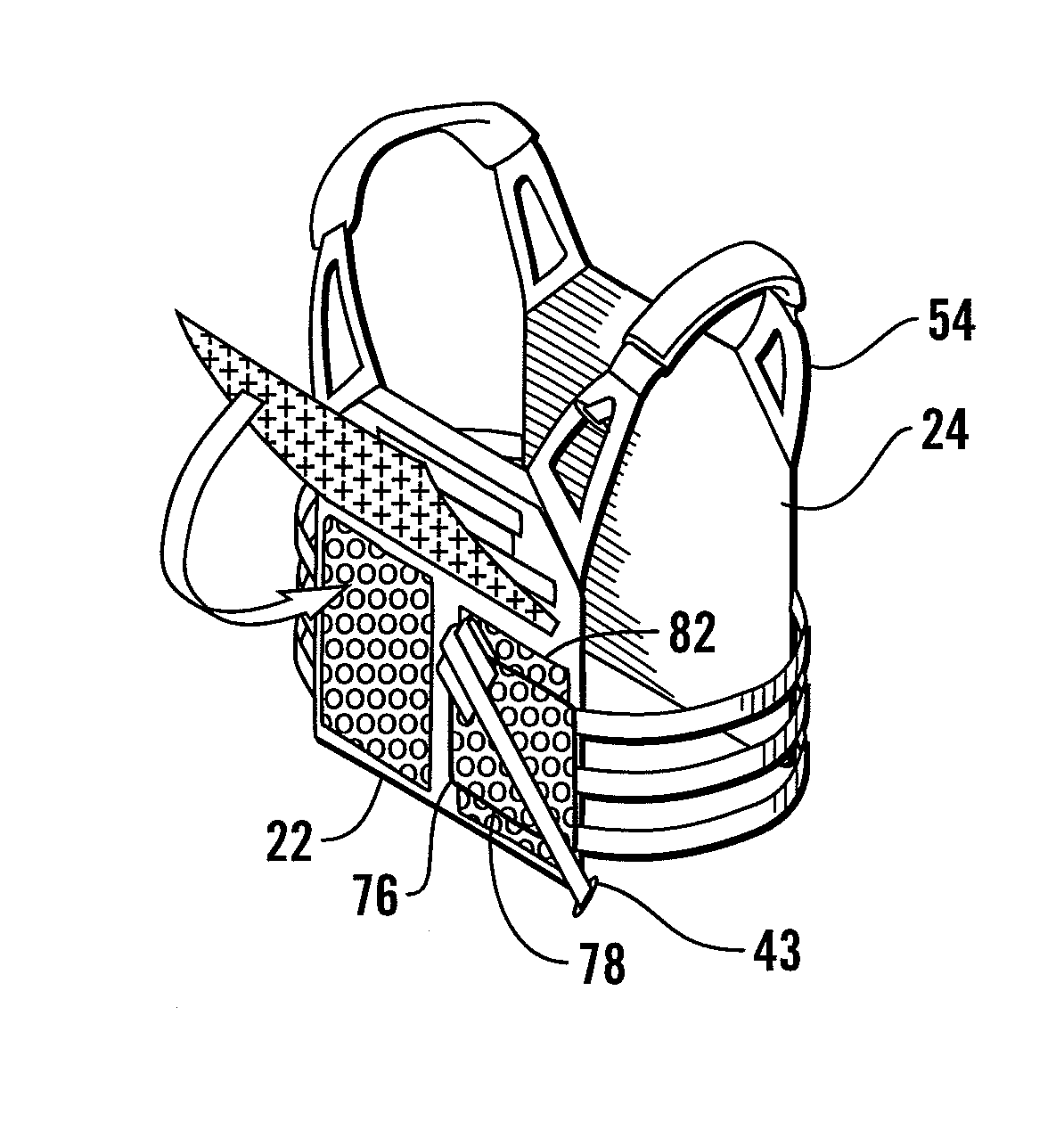

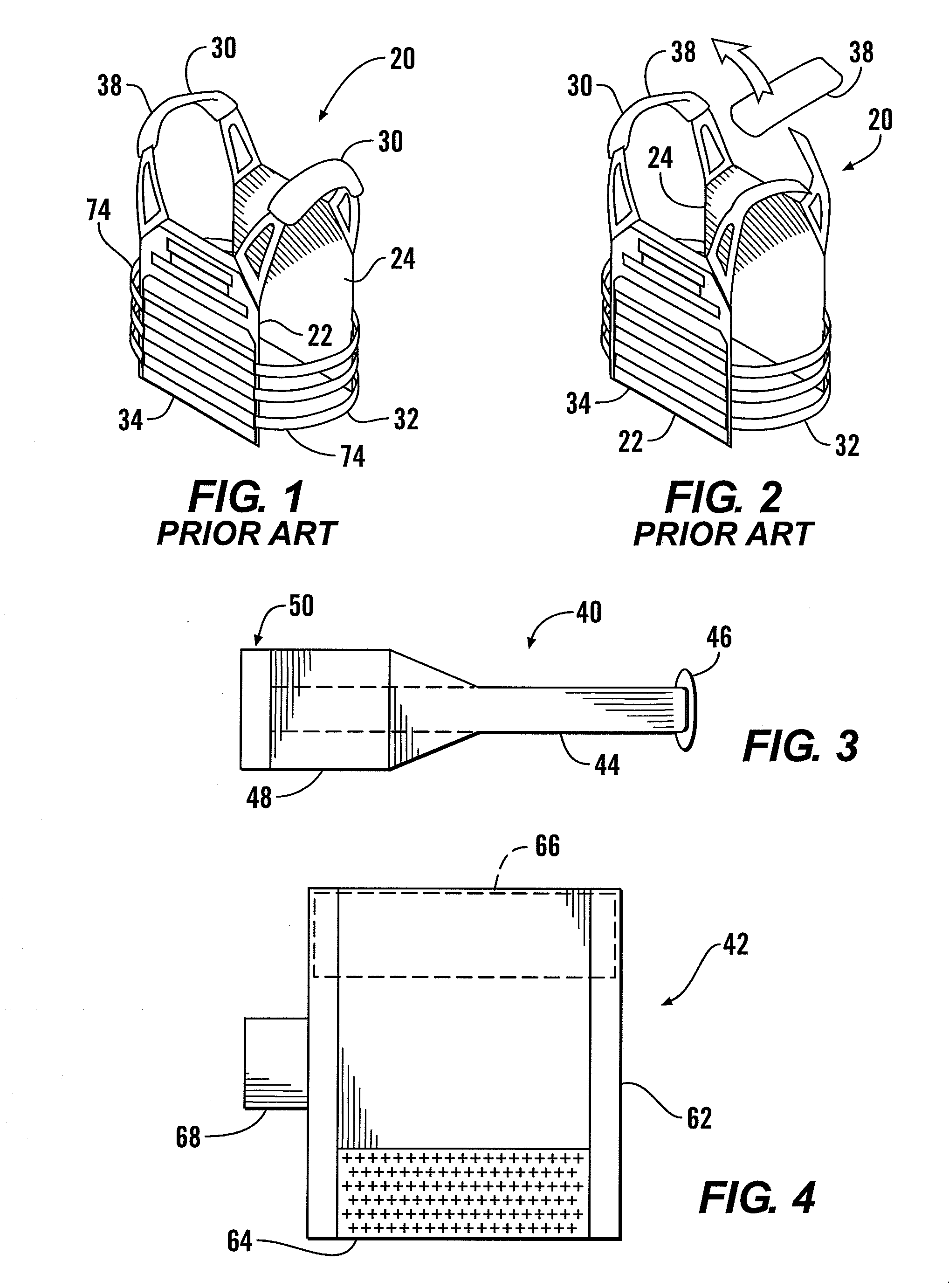

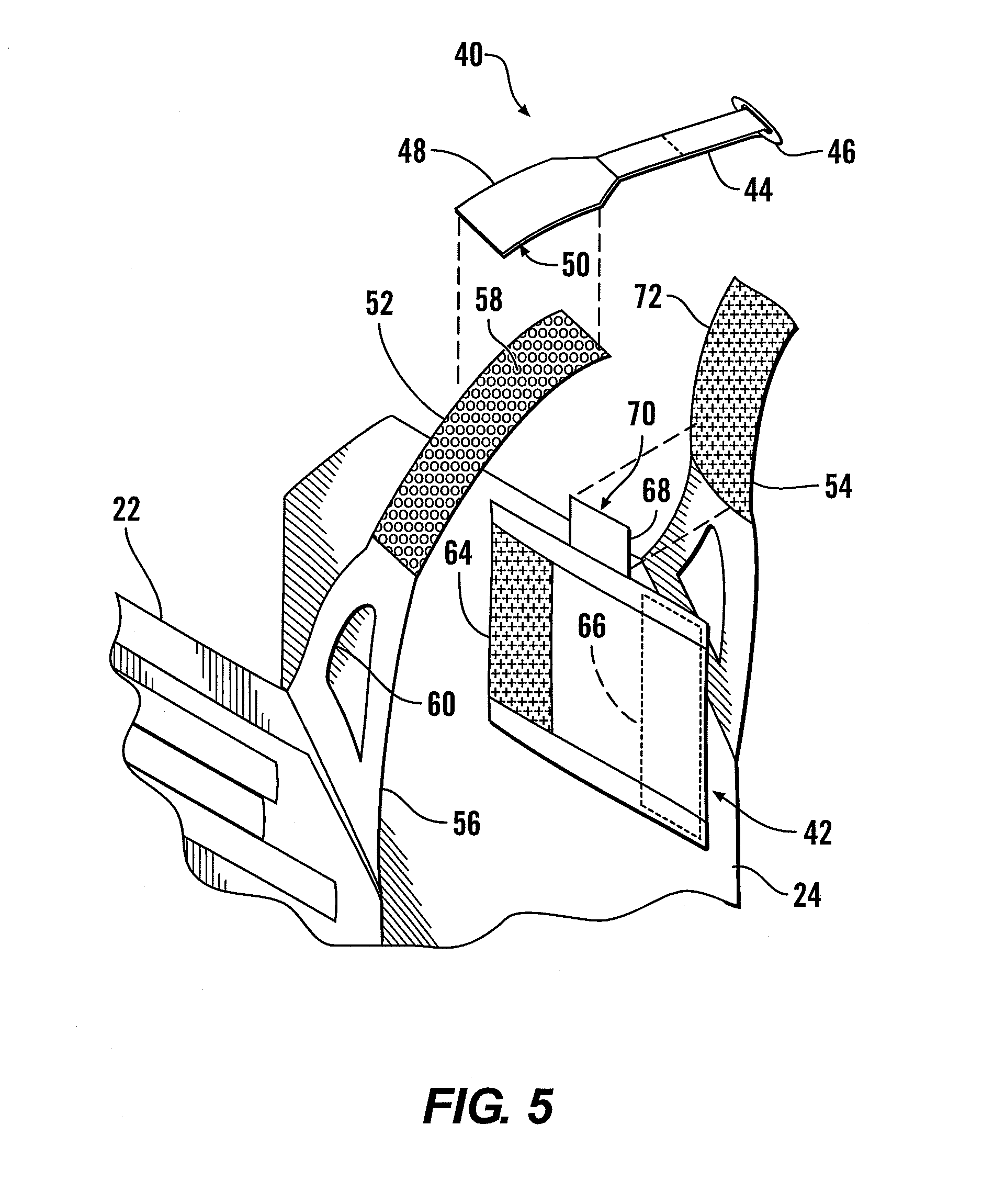

[0027]Referring more particularly to FIGS. 1-15, wherein like numbers refer to similar parts, a prior art vest 20 is shown in FIGS. 1 and 2. The vest 20 may be, for example, the JUMPABLE PLATE CARRIER™ manufactured by Crye Precision of Brooklyn, N.Y. The prior art vest 20 has a front panel 22 which is connected to a rear panel 24 by shoulder strap assemblies 30 which go over the wearer's shoulders, and a cummerbund assembly 32 which extends around the wearer's midsection. The prior art vest 20 may have downwardly opening pockets which can receive removable soft or hard armor, not shown, which serves to protect the wearer from bullets and high speed projectile fragments. The front panel 22 has a hinged front flap 34 which may be provided with horizontal rows of 1″ Mil-W-43668 Type III nylon webbing spaced 1″ apart, and reattached to the backing at 1.5″ intervals, as in the U.S. Army's PALS (Pouch Attachment Ladder System) arrangement. The cummerbund assembly 32 may be provided with P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com