Microlithography projection objective

a technology of microlithography and objective, applied in the direction of microlithography exposure apparatus, printers, instruments, etc., can solve the problems of object leakage, inability to correctly, and ineffective relief, and achieve the effect of improving image properties and effective suppression of stray or false ligh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

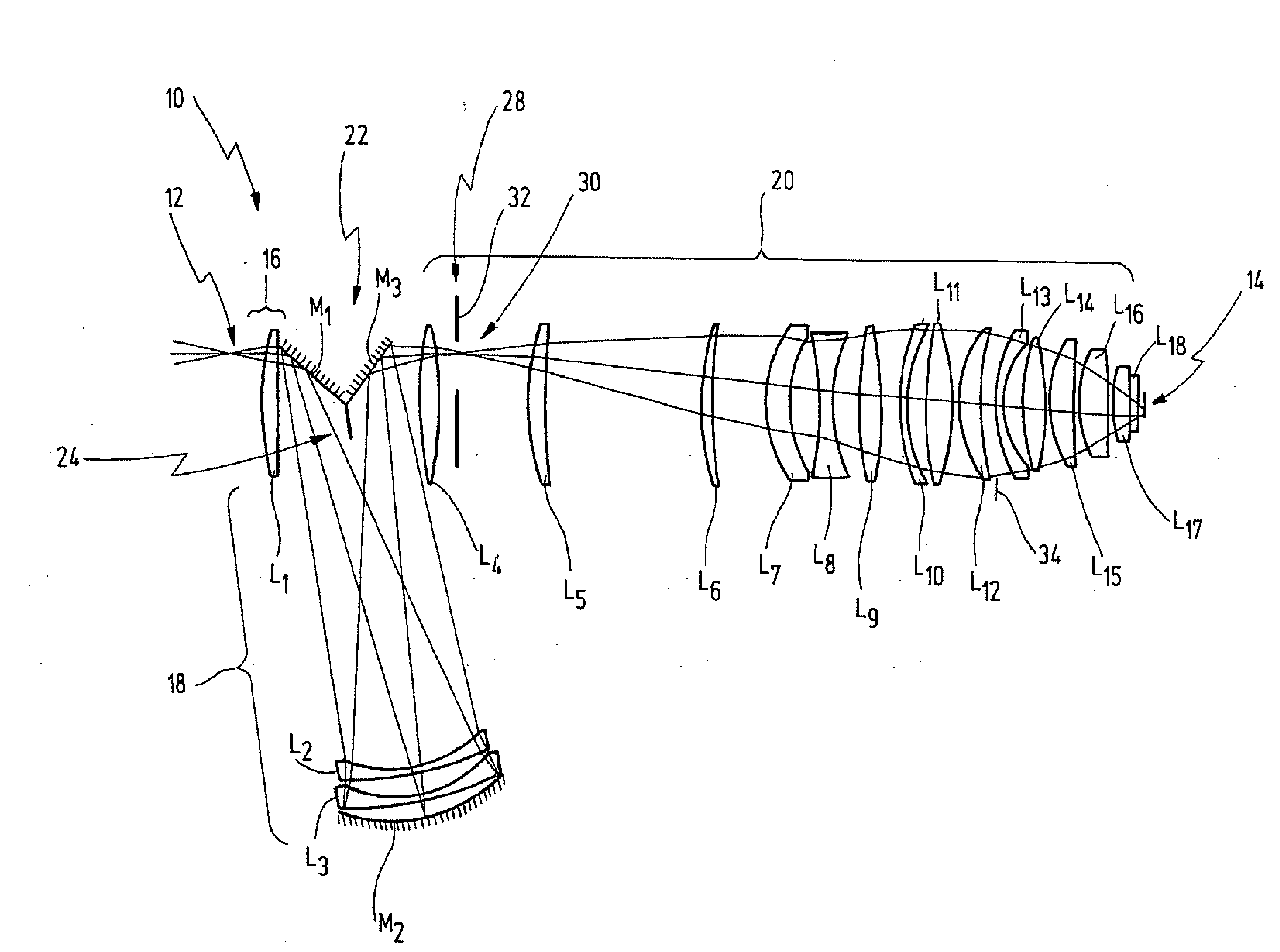

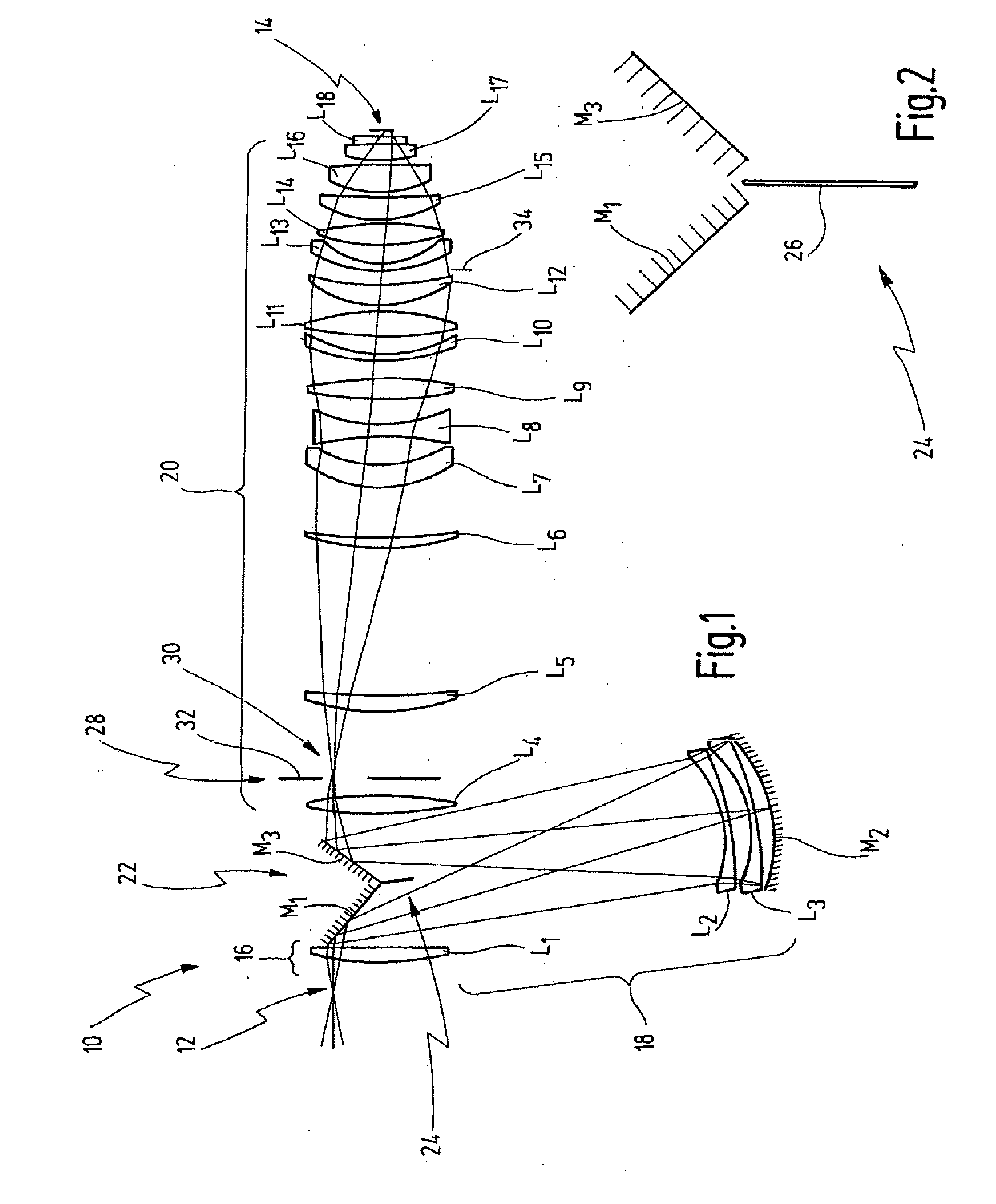

[0106]FIG. 1 shows a microlithography projection objective provided with the general reference numeral 10 intended for imaging into an image plane 14 a pattern (not shown) arranged in an object plane 12.

[0107]The projection objective 10 has a first objective part 16, a second objective part 18 and a third objective part 20.

[0108]The first objective part 16 is dioptric and is formed by a lens L1.

[0109]The second objective part 18 is catadioptric and has lenses L2, L3 and a concave mirror M2.

[0110]The third objective part 20 is dioptric and has lenses L4 to L17 and an end plate L18.

[0111]As shown in FIG. 1, the light propagation direction in the second objective part 18 differs from the light propagation direction in the first objective part 12 and in the third objective part 20. To this end, the projection objective 10 has a beam deflecting device 22, that is formed in the exemplary embodiment shown by two folding mirrors M1 and M3. The folding mirror M1 deflects the light beam comin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| optically active | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap