Railway car hatch cover

a hatch cover and railway technology, applied in railway components, transportation and packaging, etc., can solve the problems of difficulty or very time-consuming removal of the gasket from the hatch cover, purchasers cannot use a single hatch cover in a vented capacity in one instance, and non-functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

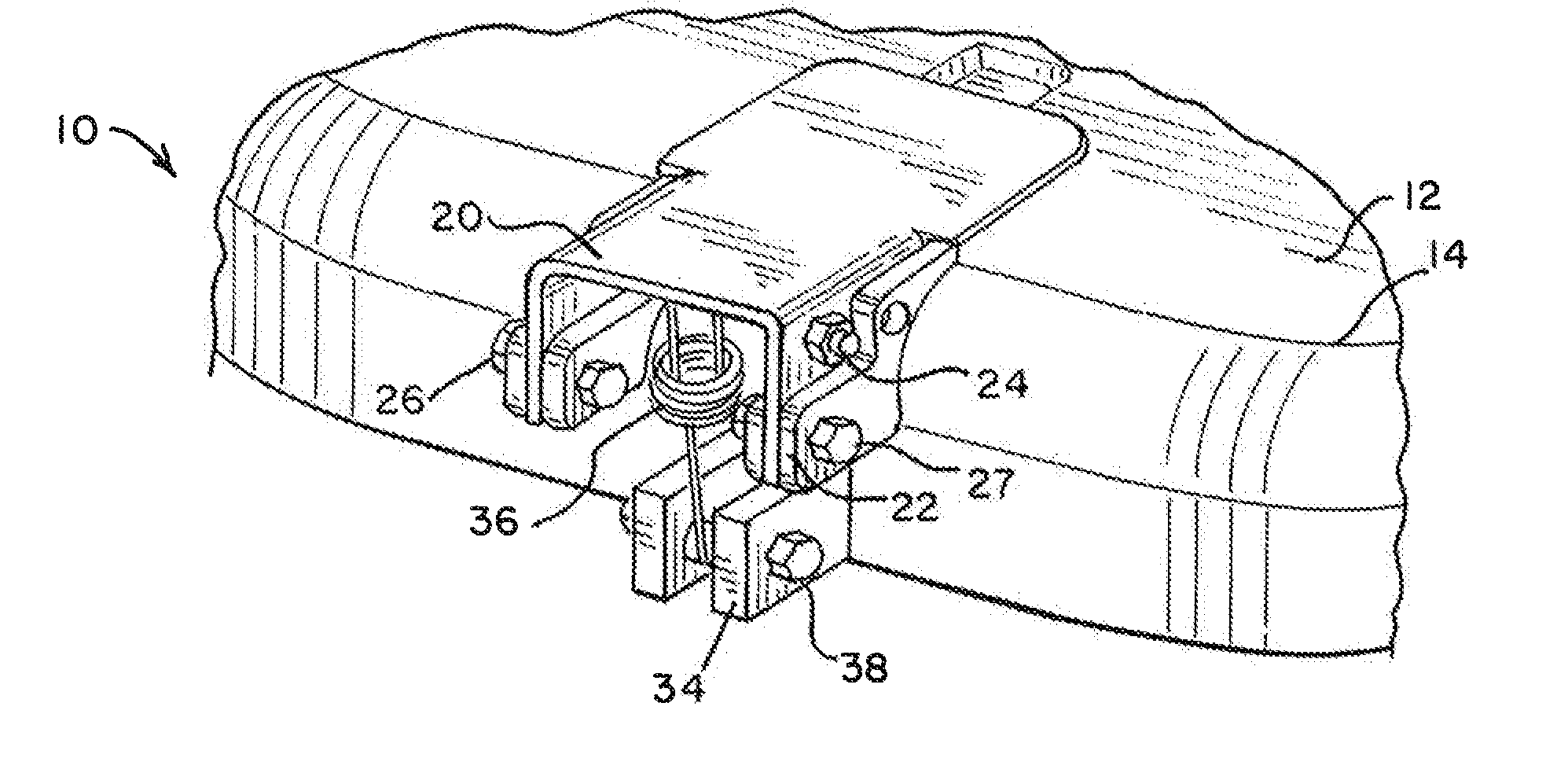

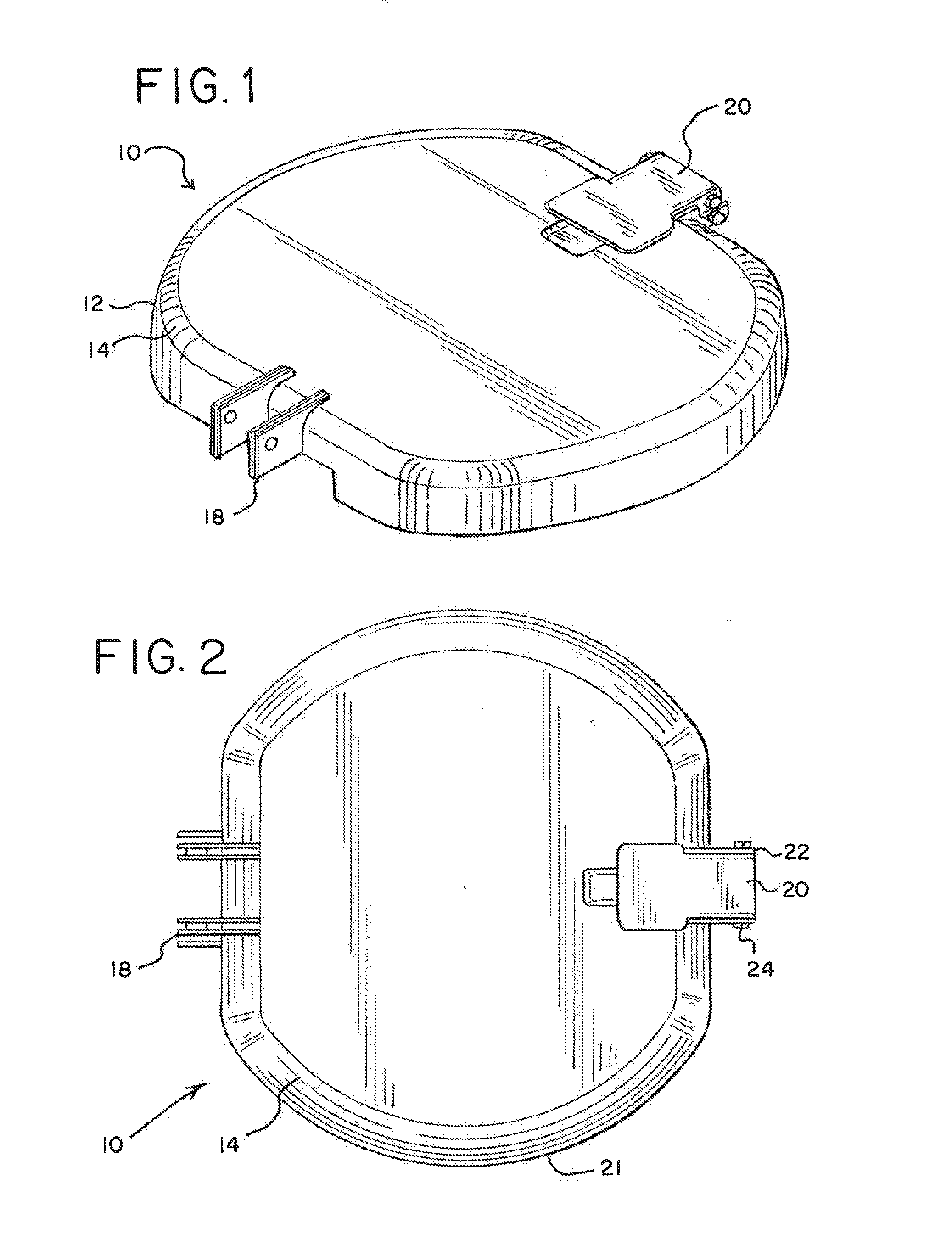

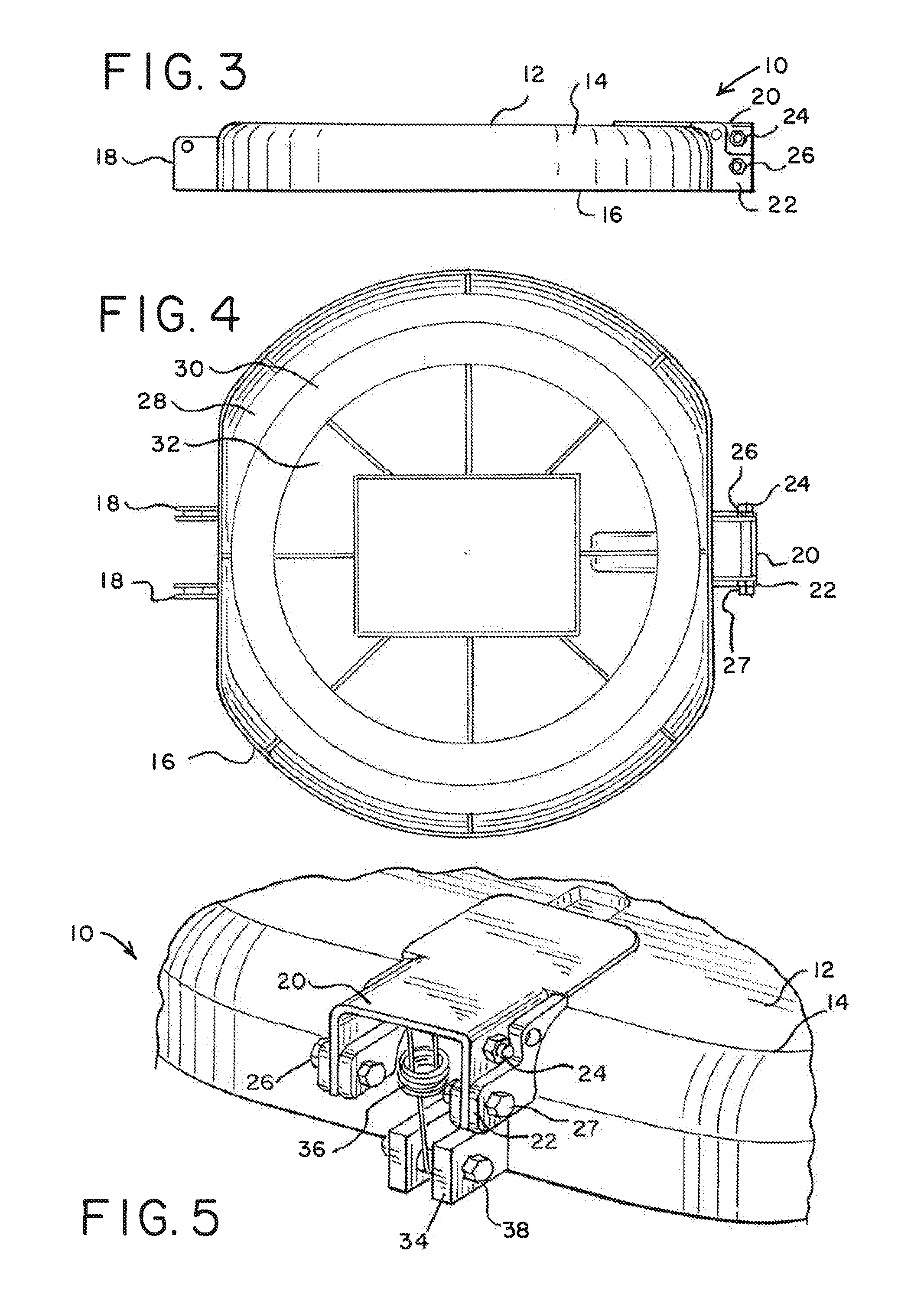

[0022]Referring now to FIGS. 1-5, a convertible railway car hatch cover is generally designated 10 and comprises an exterior shell cover 12, a mounting ring 28, and a gasket 30. The exterior shell cover 12 is generally round in the horizontal direction and dome-shaped in the vertical direction with respect to the railcar, but the exterior shell cover 12 can be any other shape as well. The exterior shell cover 12 has an outer-side 14 and an under-side 16. The exterior shell cover 12 is preferably molded from a polymeric material, but it can also be made from a metallic material. Hinges 18 connected to the outer-side 14 of the exterior shell cover 12 pivotally connect the convertible railway car hatch cover 10 to a set of hatch hinges 34 on top of a railway car (not shown). The hinge allows the exterior shell cover 12 to rotate up to 180 degrees with respect to the closed position.

[0023]A gasket 30 is mounted to a mounting ring 28 by pressing the gasket 30 into the mounting ring 28, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com