Apparatus for Transporting Pollution from a Body of Water

a technology of pollution transport and floatable materials, applied in the field of harvesting floatable materials, can solve the problems of mass rotting, seaweed quantity often far outweighs the benefit of ecosystem, starvation and destruction of coral reef systems, etc., and achieves the effects of lowering the temperature of wash water, lowering the temperature of seaweed, and lowering the rate of decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

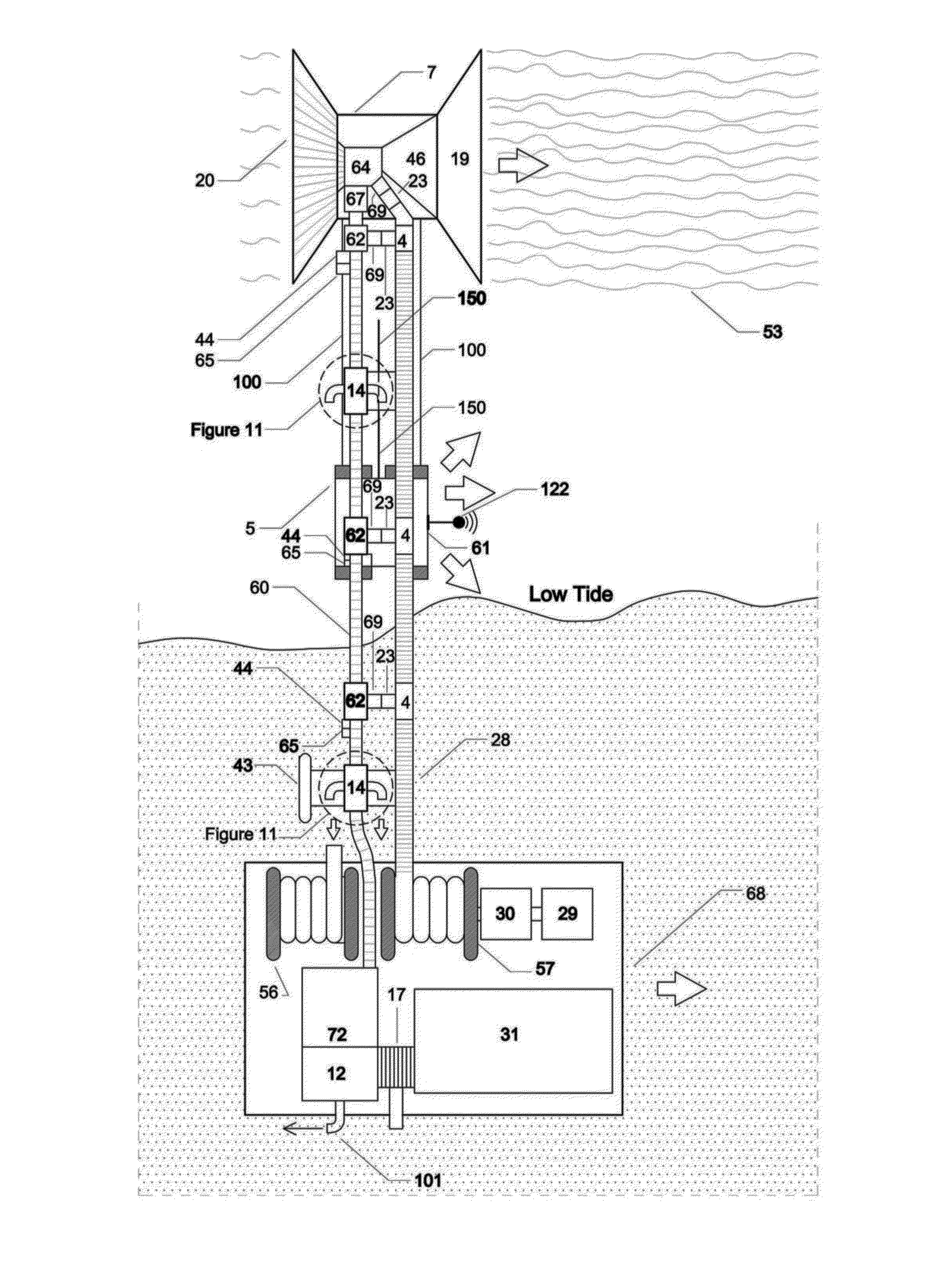

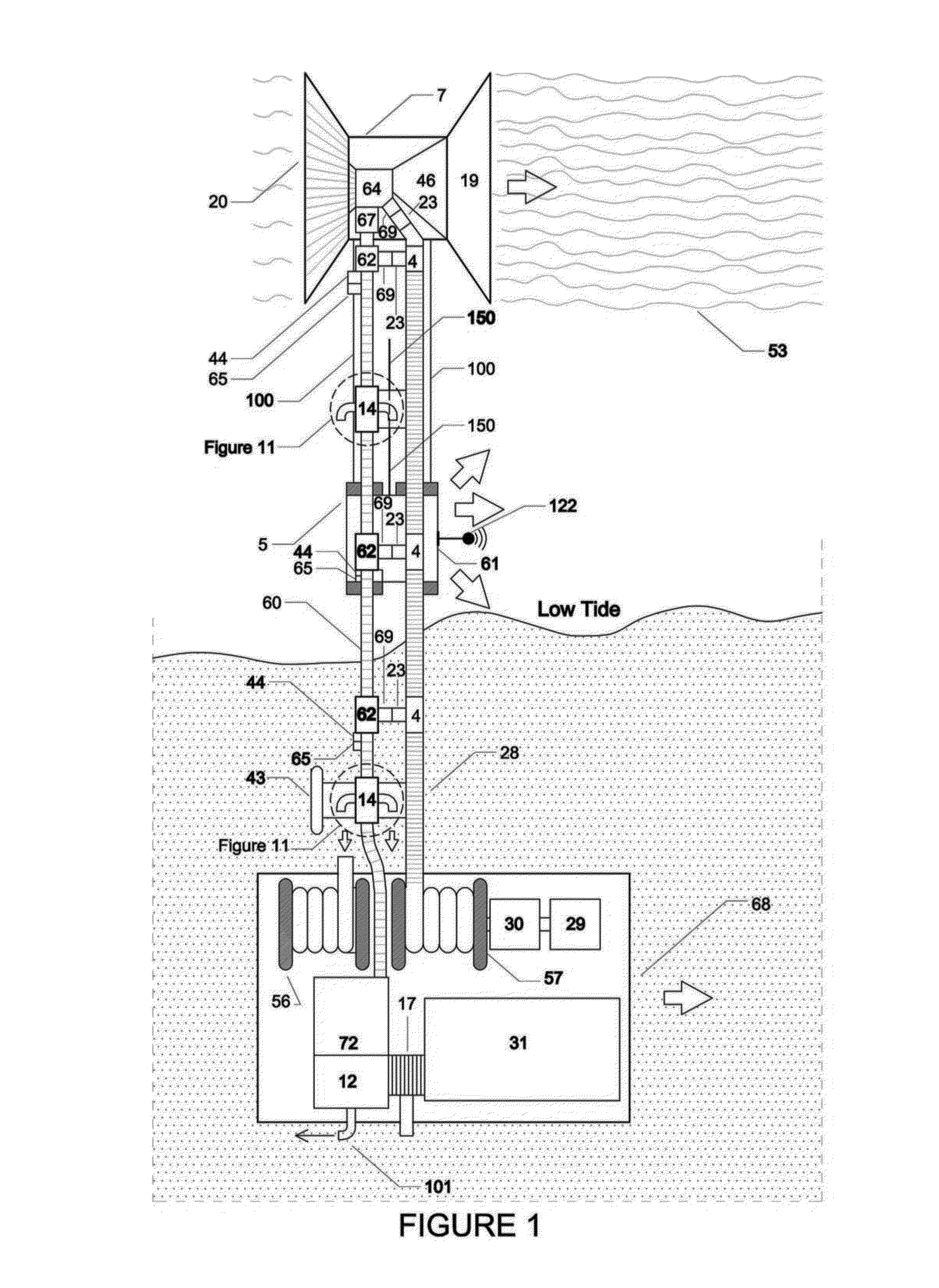

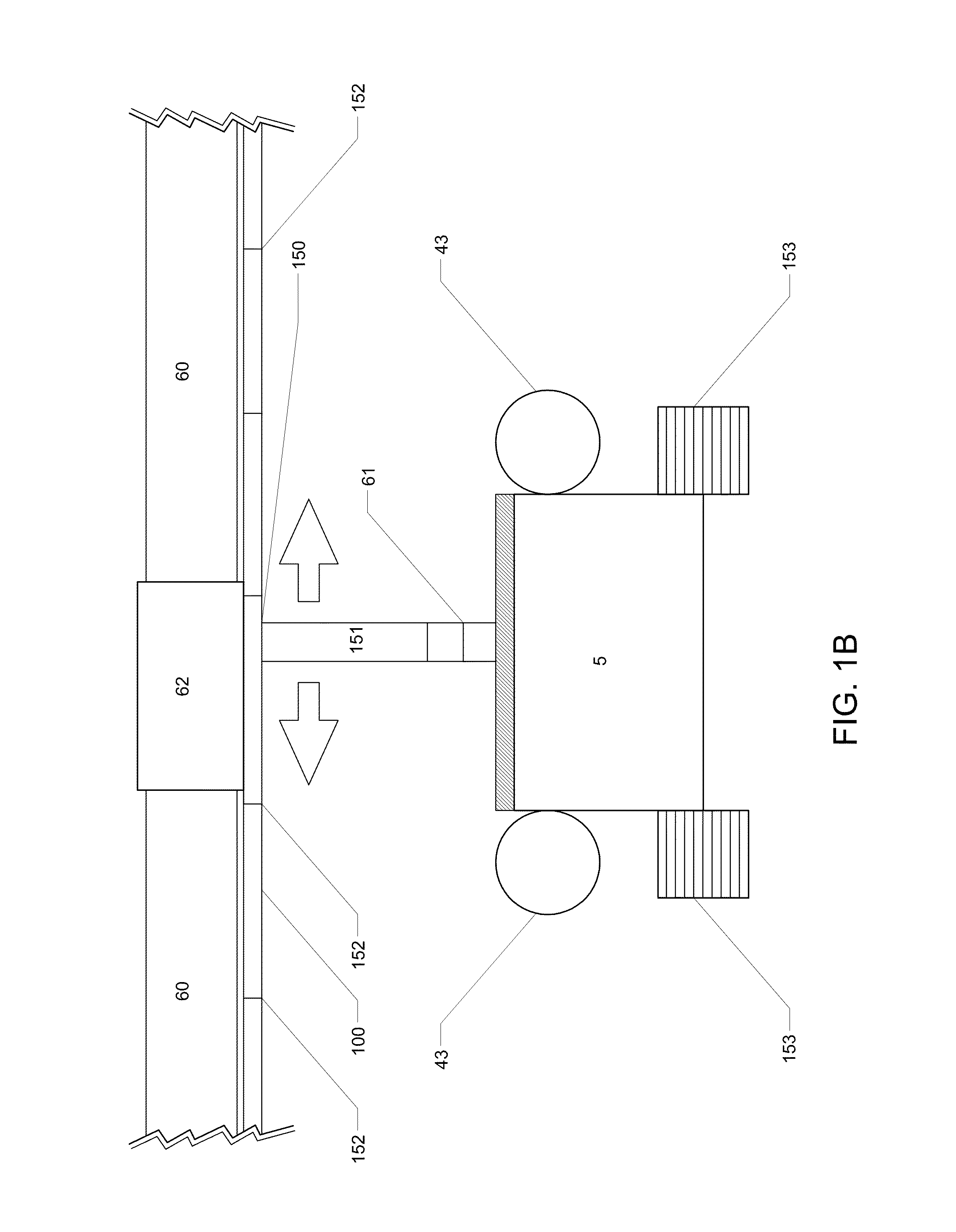

[0020]In brief, a floatable material (e.g., seaweed; fibrous material used in oil-spill clean up or a nuclear disaster) harvester is disclosed, including a vacuum source, a transport hose, and a floatable-material receiver. In one embodiment, the transport hose has at least one air inductor / intake along its length, which allows air to enter the transport hose to accelerate its contents, by negative pressure air induction. The air inductor may have a valve controlled by an air meter. In another embodiment, a plurality of air inductors is shown. In some embodiments, a plurality of valves is shown. In another embodiment, a transport hose has at least one floatable-material thruster along its length, comprised of at least one nozzle, which provides pressurized fluid (e.g., air or water) in the direction of the flow of the harvested floatable material by positive pressure induction. In some embodiments, a plurality of floatable-material thrusters is shown. In some embodiments, the direct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com