Cover unit with adapter, cover, and sealing film for a container

a technology for containers and covers, applied in the direction of transit packaging, packaging, clamping mechanisms, etc., can solve the problems of system requirements for relatively high investment in facilities and machines, waste of a large proportion of materials, and inefficiency, and achieve the effect of simple, rapid and inexpensive manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

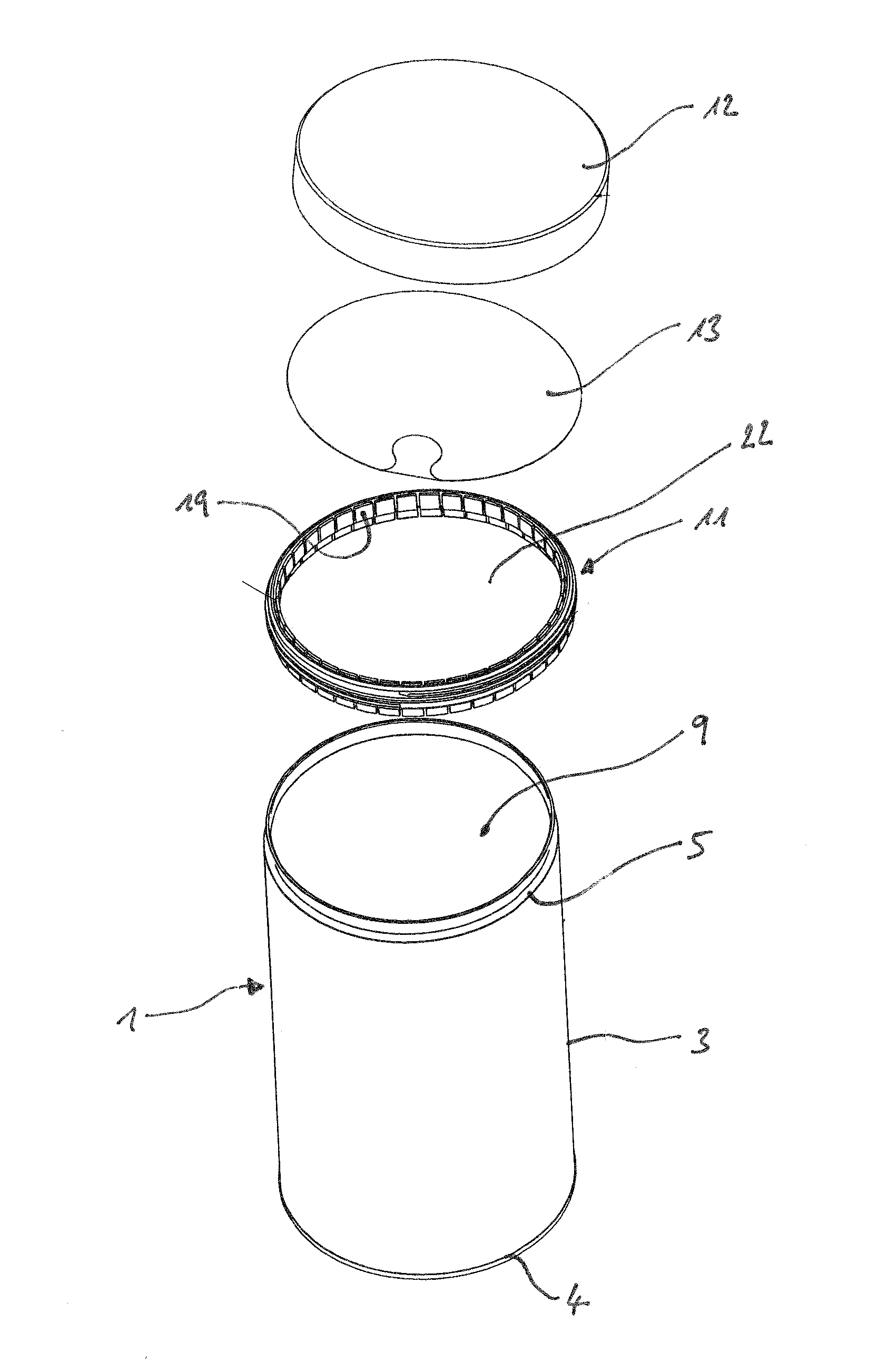

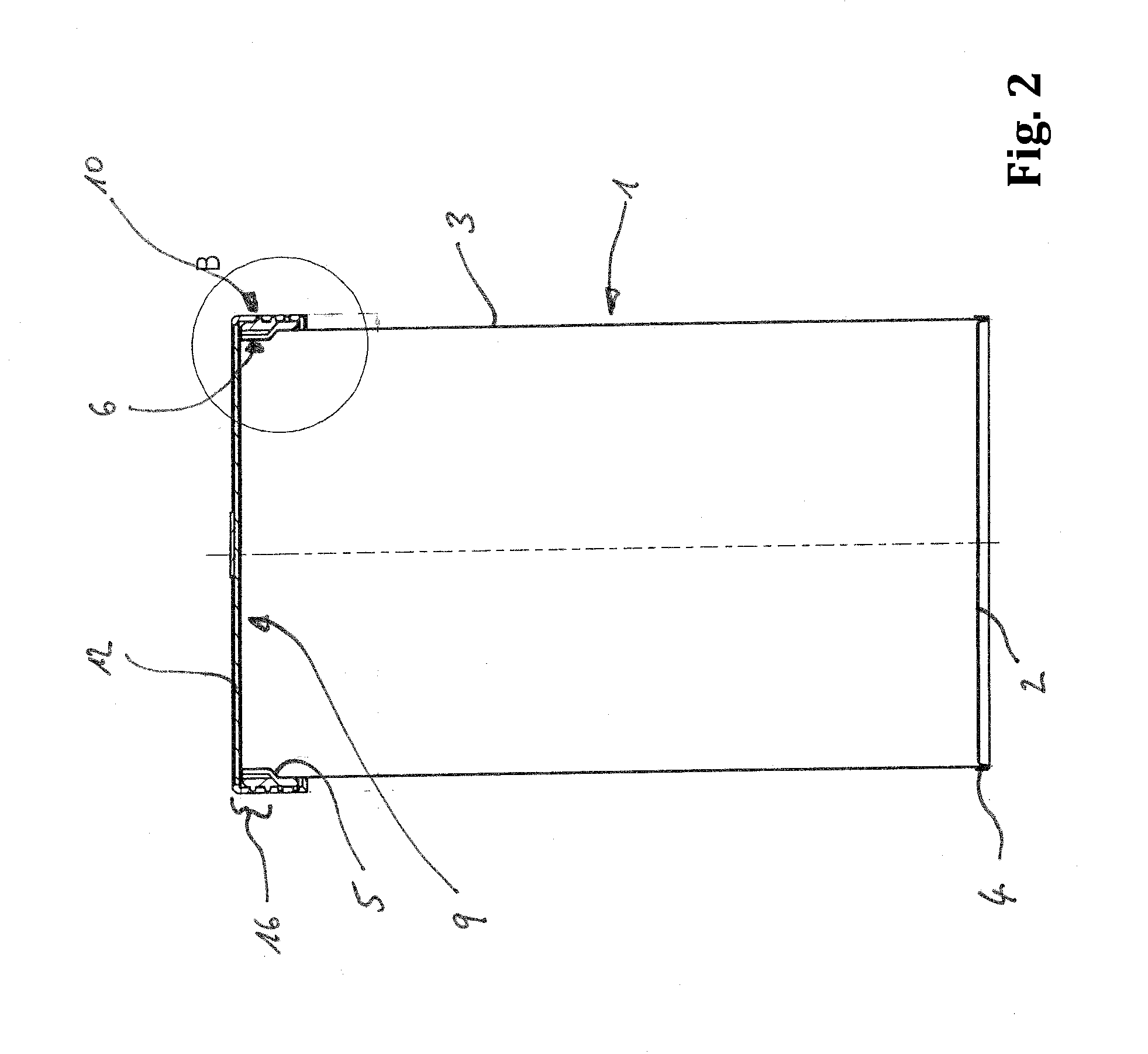

[0032]FIG. 1 is a plan view of a metal container 1. It is of a substantially cylindrical shape and has a container base 2 and a container wall 3. The container base 2 and container wall 3 are tightly interconnected by a fold 4. As can be seen in particular in FIG. 3, the container wall 3 is formed into a neck portion 16 in the upper region thereof. The container wall 3 here is deformed in the direction of the container interior and forms an oblique shoulder 5 and a peripheral depression 6. At the upper end, the container wall 3 is flanged to form a flanged edge 7, which forms a sealing edge 8 on the face thereof remote from the container base 2. Said edge surrounds a filling opening 9 of the container 1.

[0033]The filling opening 9 is sealed by a cover unit 10, which has a substantially annular adapter 11, a cover 12, a sealing film 13 and a resilient intermediate layer 14. The cover 12 and adapter 11 are releasably screwed together via a thread 15. The cover unit 10 can be placed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com