Insulating sealing element for head-of-wall joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

DETAILED DESCRIPTION OF THE DRAWINGS

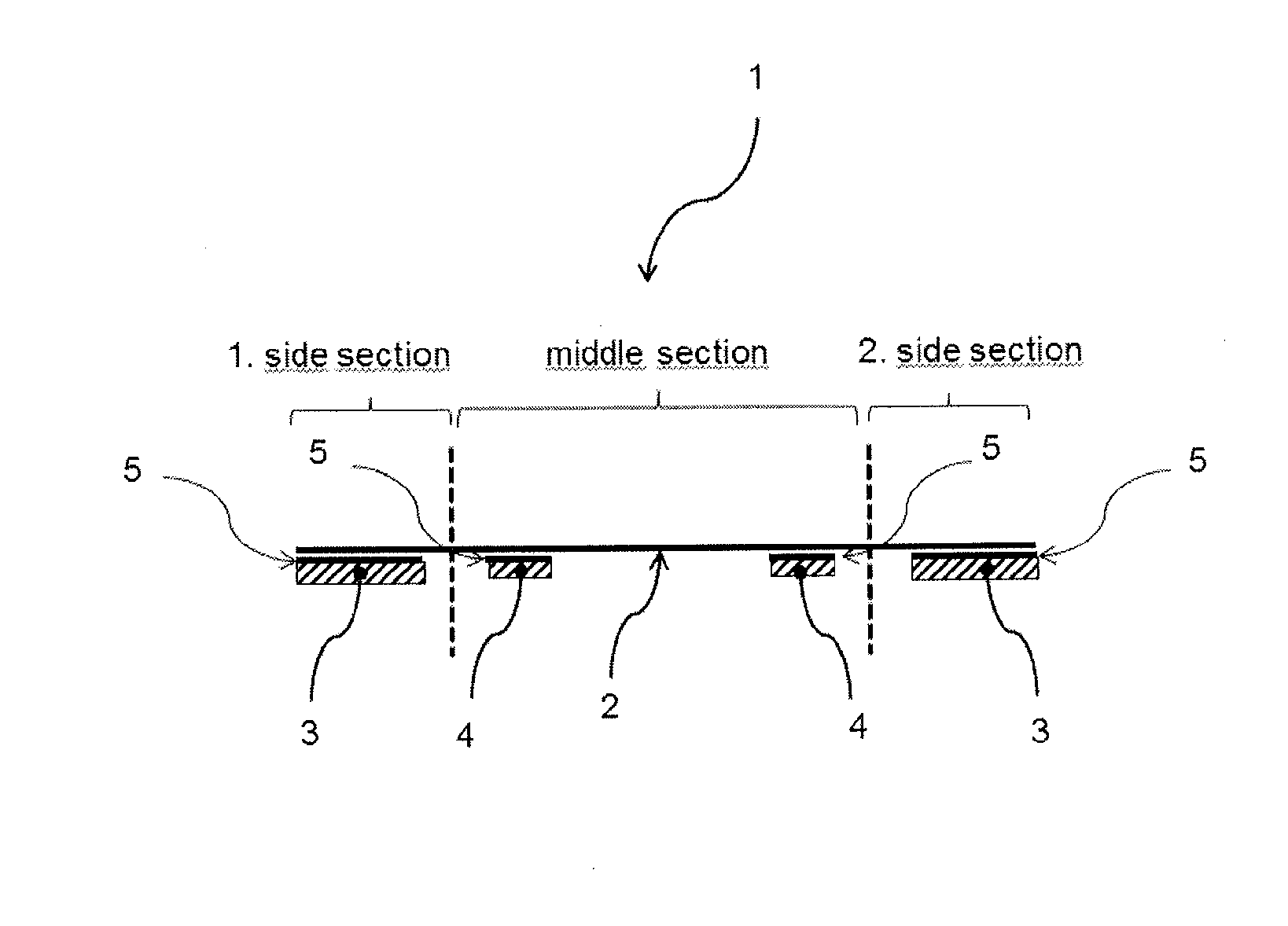

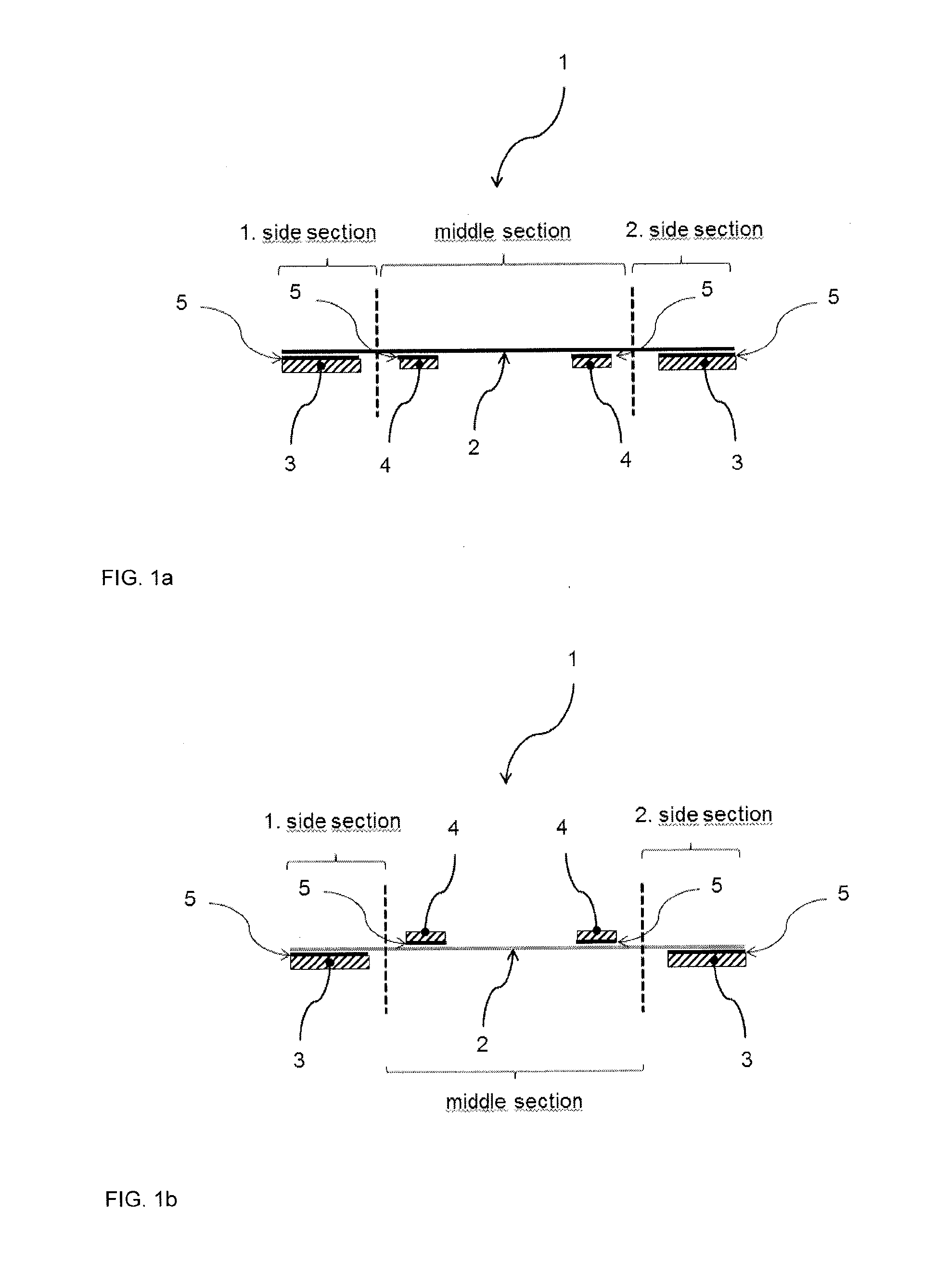

[0055]FIG. 1a illustrates an insulating strip assembly 1, which is also referred to herein as insulating strip. The insulating strip 1 is an elongated strip assembly that preferably is constructed as an integrated assembly of multiple components. The insulating strip 1 may be supplied on a roll, in a folded arrangement or any other suitable manner. Preferably, the insulating strip 1 is provided as a separate component that is applied to a head-of-wall on site, as is described in greater detail below.

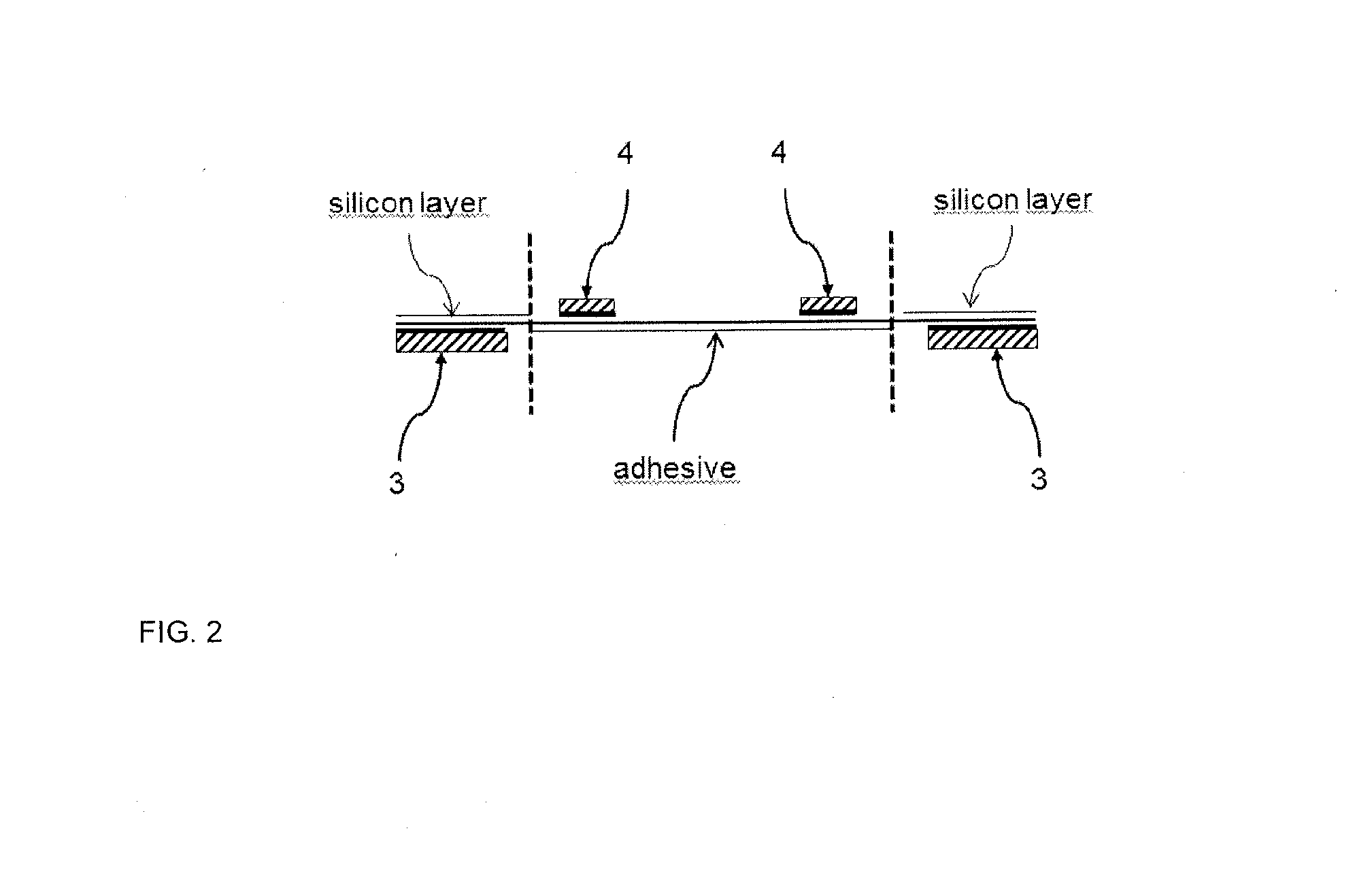

[0056]The illustrated insulating strip 1 includes fire-resistant material strips 3 and 4. All fire-resistant strips 3 and 4 are positioned on the same face of the support layer 2 spaced apart from each other. The fire-resistant strips 4 are arranged at a certain distance from each other to form a section inbetween where no insulating material is arranged. The insulating strips 3 and 4 may be secured to the support layer 2 by adhesives 5 applied to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical resistance | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com