Boot for hooves

a technology for hooves and boots, applied in the field of boots for hooves, can solve the problems of imbalance in the hoove, different types of damage to the hooves and extremities of horses, and the inability of metal-based hooves to follow the expansion and contraction of the hoove, and achieve the effect of easy mounting and dismounting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

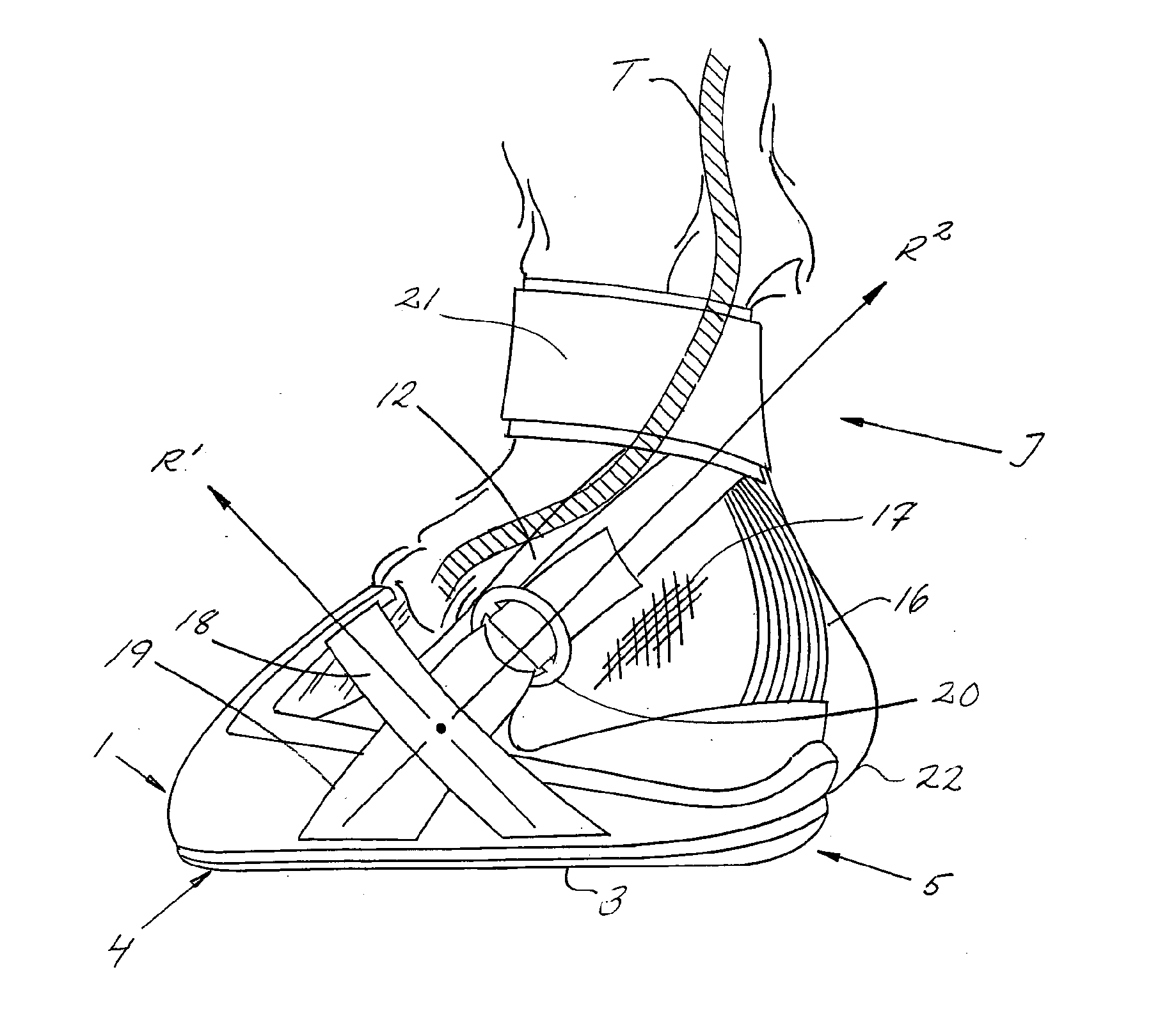

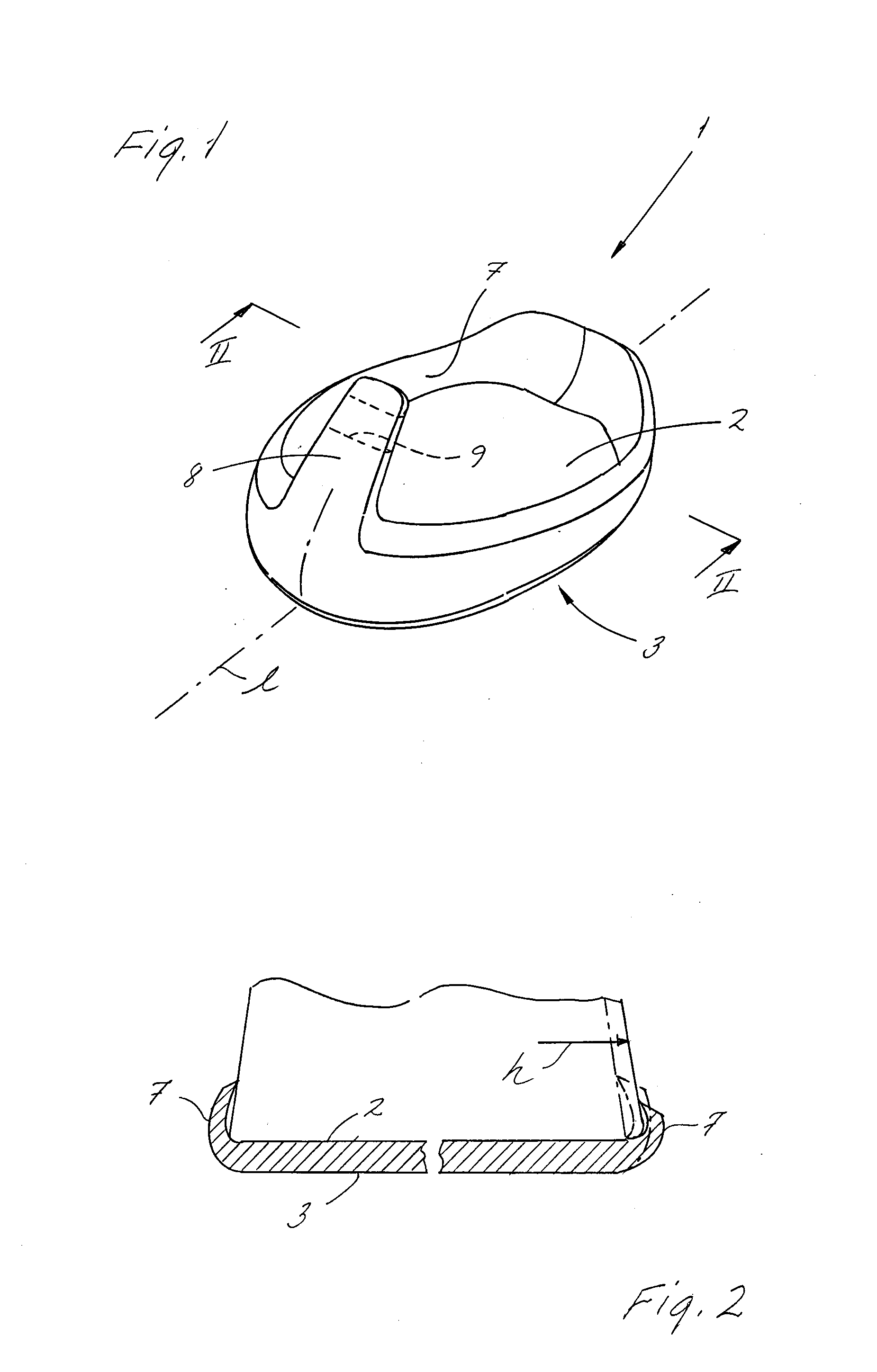

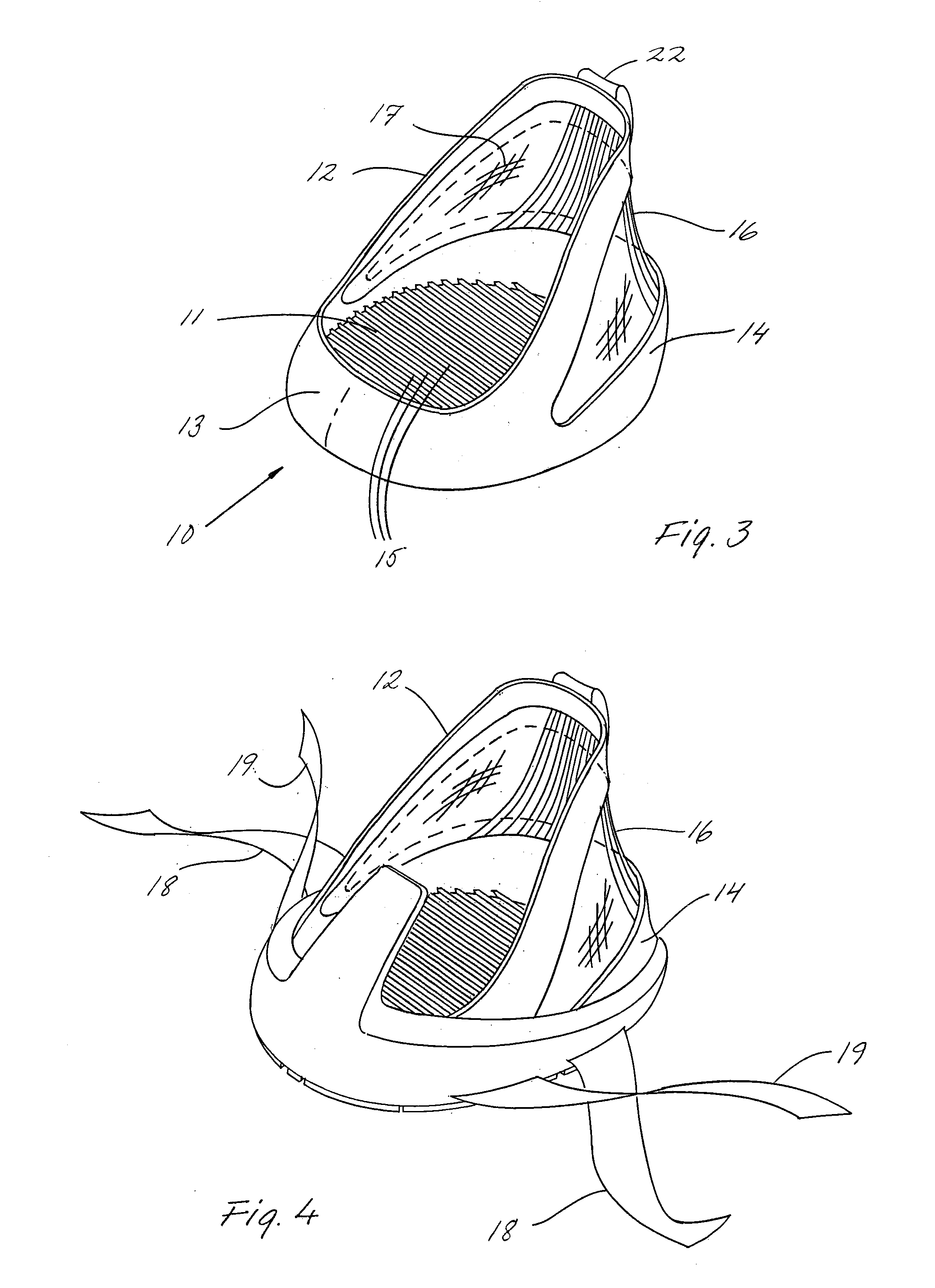

[0060]FIG. 1 shows a sole 1 included in a hoof boot according to the invention. The sole 1 is cup-shaped and comprises a bottom 2 the shape of which essentially corresponds to the underside of a hoof, and the underside of which forms a ground contact surface 3. The ground contact surface 3 is best seen in FIG. 6. The bottom and ground contact surface of the sole extend in the longitudinal direction 1 of the hoof boot between a front toe portion 4 and a rear heel portion 5, see FIG. 5. A protruding edge 7 runs around the bottom of the sole, and has a tongue 8 in the toe portion having such a length that the tongue extends a good distance up along the capsule of the hoof in the mounted position of the hoof boot, as is best shown in FIGS. 7 and 8. A slot 9 mouths in the sides of the tongue 8 and extends through the tongue in ways illustrated by dashed lines in FIG. 1. The slot 9 is adapted for leading through a strap arranged and operative in the way described below. Said strap may alt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com