Container crane

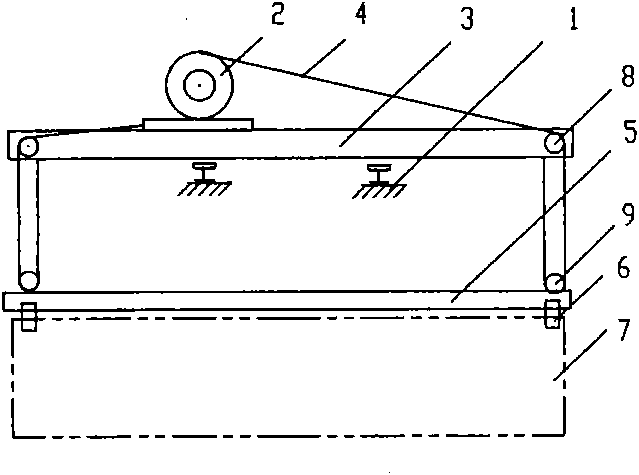

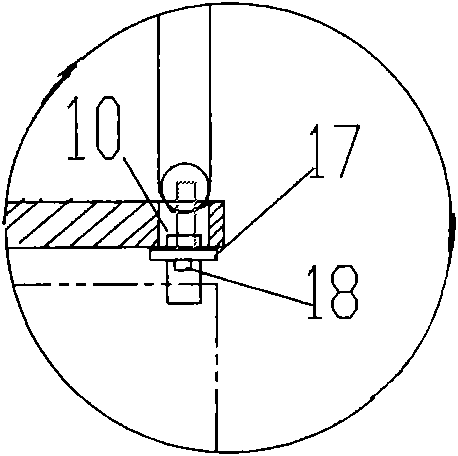

A container and crane technology, applied in transportation and packaging, load hoisting elements, cranes, etc., can solve the problems of increasing the weight of the spreader, the space occupied by the steel wire rope, and reducing the lifting height, so as to reduce the height and weight of the overall structure, improve the Efficiency and safety of loading and unloading, the effect of reducing the lifting distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The bridge on the inland waterway is the main obstacle that affects the navigation of inland waterways. The headroom from the bridge to the water surface is certain. Therefore, in the design of container cranes on inland river container ships, ordinary container cranes with walking trolleys, trolleys and cranes are used. There is too much wasted space between tools, and the design is very difficult or even impossible. The present invention can solve this problem.

Embodiment 2

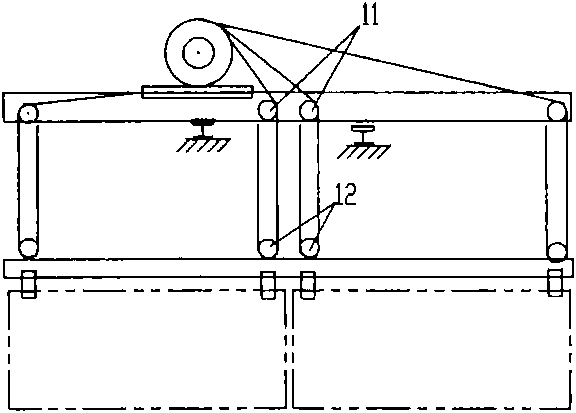

[0060] At present, most of the weight of container cargo is weighed by the ground scale. In many cases, the weighing needs to be completed when the crane is hoisted. At this time, one or more "hook scales" need to be added between the trolley and the spreader. "This scale needs to take up a lot of space, which is difficult to implement on ordinary container cranes. The present invention can solve this problem.

Embodiment 3

[0062] Large container cranes such as port container loading and unloading bridges and container yard gantry cranes have problems such as heavy cranes and spreaders, high energy consumption, poor aerial attitudes of spreaders and containers, poor stability, and low loading and unloading efficiency and safety. The present invention can overcome these drawbacks to a certain extent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com