Removable motor housing for a plant material trimming device

a technology of plant material and motor housing, which is applied in the direction of cutting tools, food processing, food science, etc., can solve the problems of inefficiency in the operation of plant trimming devices, wear of contact points between motors, tumblers and blade devices,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

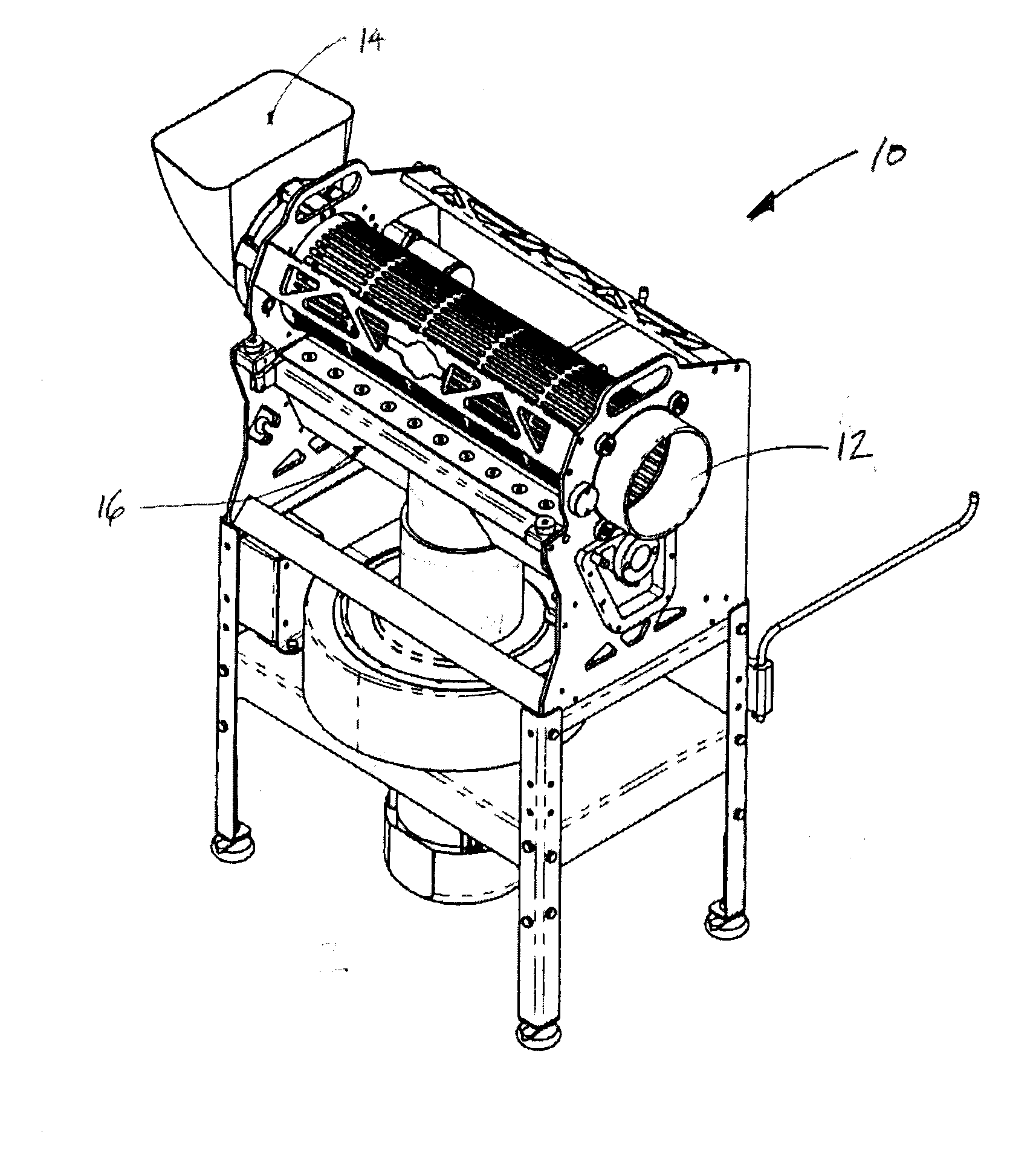

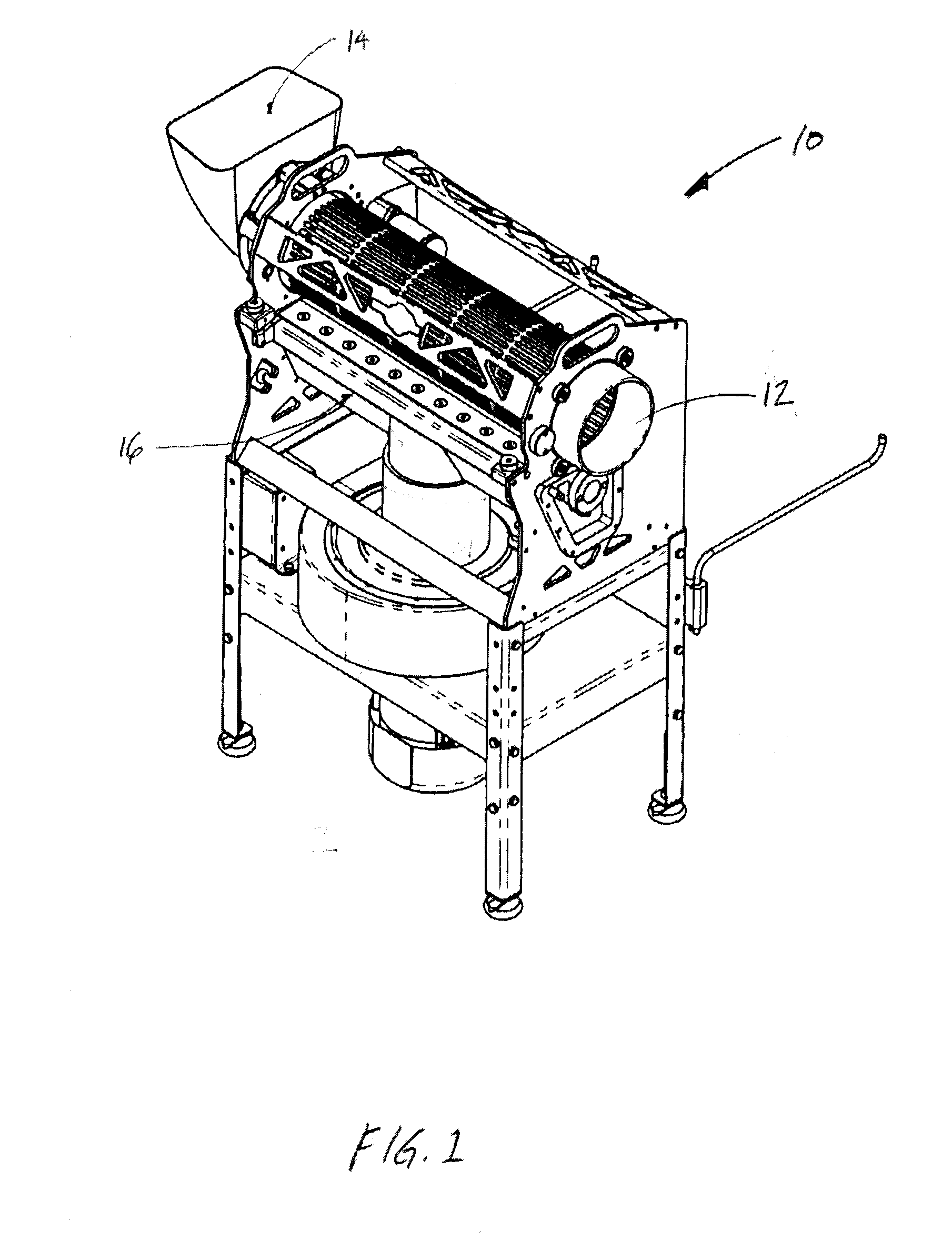

[0034]Referring to FIG. 1, a plant material trimming device 10 is depicted. The device 10 includes a tumbler 12 residing inside of the device. Plant material that requires trimming is inserted into a hopper 14 which then feeds the plant material into the tumbler 12. A removable blade mechanism 16 is situated inside of the device 10 and adjacent the tumbler 12. As the plant material is tumbled in the tumbler 12, the blade mechanism 16 cuts the plant material in a scissor-like fashion as the plant material is exposed between the blade mechanism and tumbler walls. Referring to FIG. 2, a removable motor housing 18 is also situated inside the device 10 and adjacent the tumbler 12.

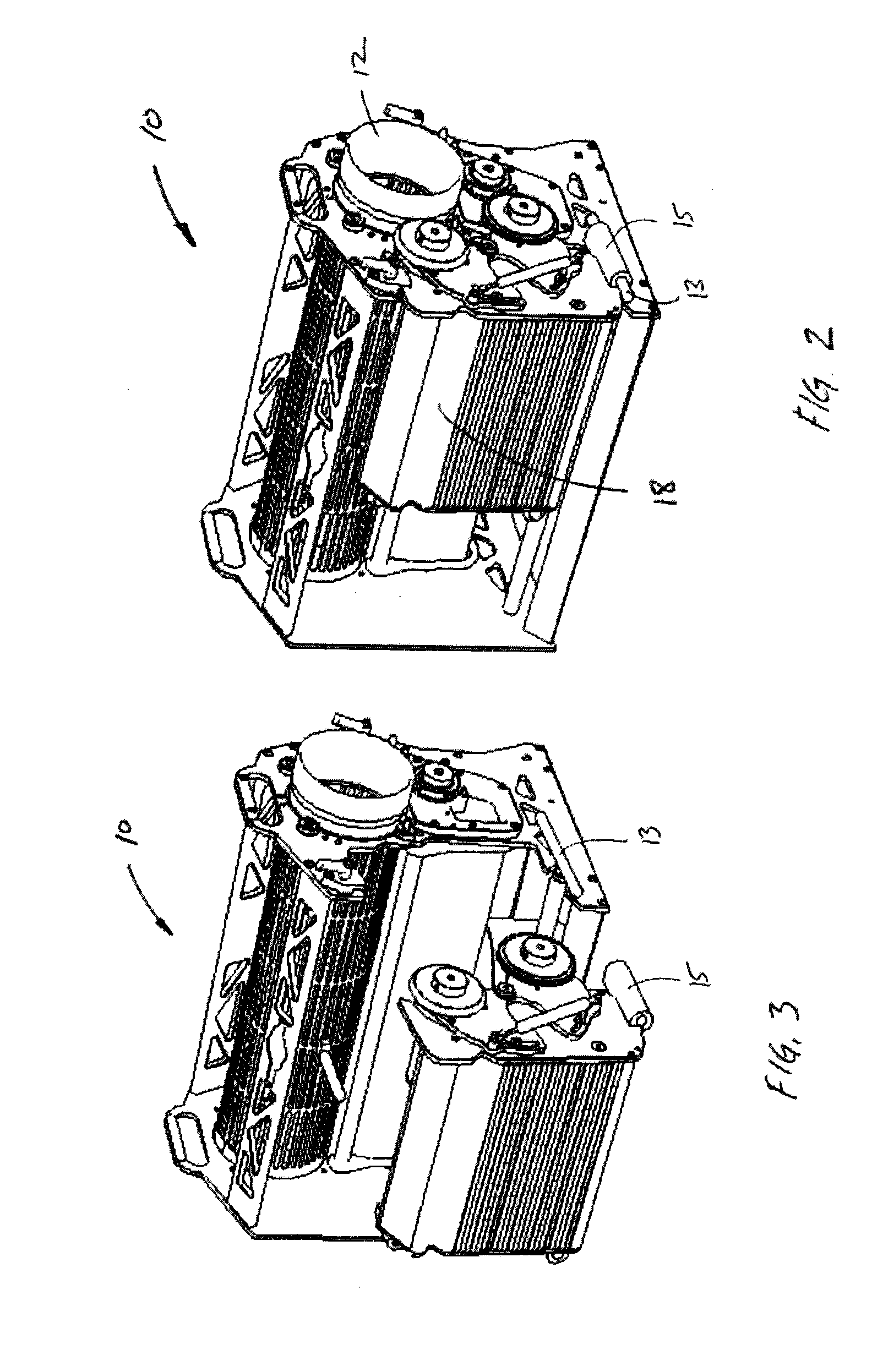

[0035]Referring to FIG. 4, the plant trimming device 10 has an input shaft 20 in communication therewith. The removable housing 18 includes a first motor housing 22 connectable to the plant trimming device. As depicted in FIGS. 2 and 3, the first motor housing may be slidably connected to the plant trimming devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| constant force | aaaaa | aaaaa |

| direct mechanical communication | aaaaa | aaaaa |

| indirect mechanical communication | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com