Golf club shaft

a golf club and shaft technology, applied in the field of shafts, can solve the problems of “heavy” feel during the swing motion and the ball speed does not always increase, and achieve the effects of reducing the rate of head speed reduction, maximizing effect, and increasing head weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

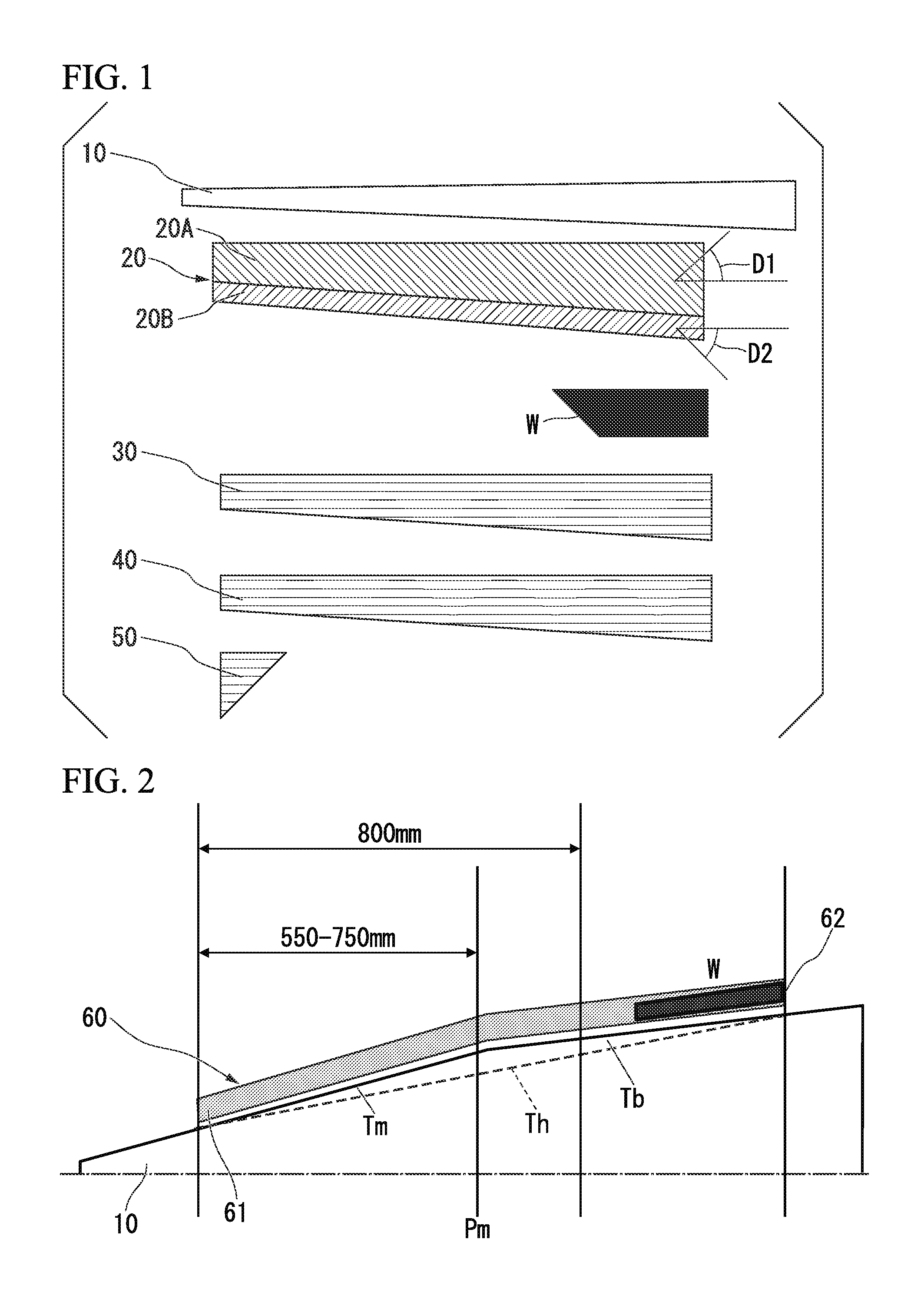

[0106]Example 1 of the present invention is described with reference to FIG. 1. Around the mandrel 10 of FIG. 1 (diameter at the tip end=6.0 mm, diameter at the butt end=13.3 mm), the following layers were wrapped in that order: an angle layer 20 (prepreg K: two sheets of prepreg K were laminated with fiber orientation angles of ±45 degrees to the longitudinal direction of a shaft), a weight layer (W) (prepreg W1: laminated with a fiber orientation angle of zero degrees to the longitudinal direction of a shaft), a first straight layer 30 (prepreg D), a second straight layer 40 (prepreg D), and a tip reinforcement layer 50 (prepreg H: wrapped from the tip end to a point 250 mm upward). After thermosetting the resin, the mandrel 10 was pulled out. Next, a section 10 mm from the tip end and a section 12 mm from the butt end were cut off and the remaining portion was polished. Accordingly, a shaft was obtained to have a full length (LS) of 1168 mm, a narrow-end outer diameter of 8.50 mm...

example 2

[0109]The shaft was produced the same as in Example 1 except that the number of wrappings in the angle layer was changed and the following modification was made to adjust the total weight of the shaft. The number of wrappings in the angle layer was adjusted not only in the present example but in each example. However, that description is omitted.

[0110]The weight percentage of the weight layer (W) was set at 13.5%.

example 3

[0111]The shaft was produced the same as in Example 1 except for the following change.

[0112]The weight percentage of the weight layer (W) was set at 17.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com