Methods, systems and components for multi-storey building construction

a multi-storey building and building technology, applied in the direction of building components, portable lifting, construction materials, etc., can solve the problems of high labor intensity, inherently slow overall process, and high-pressure concrete pumping equipment requirements, and achieve the effect of facilitating the erection of wall sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

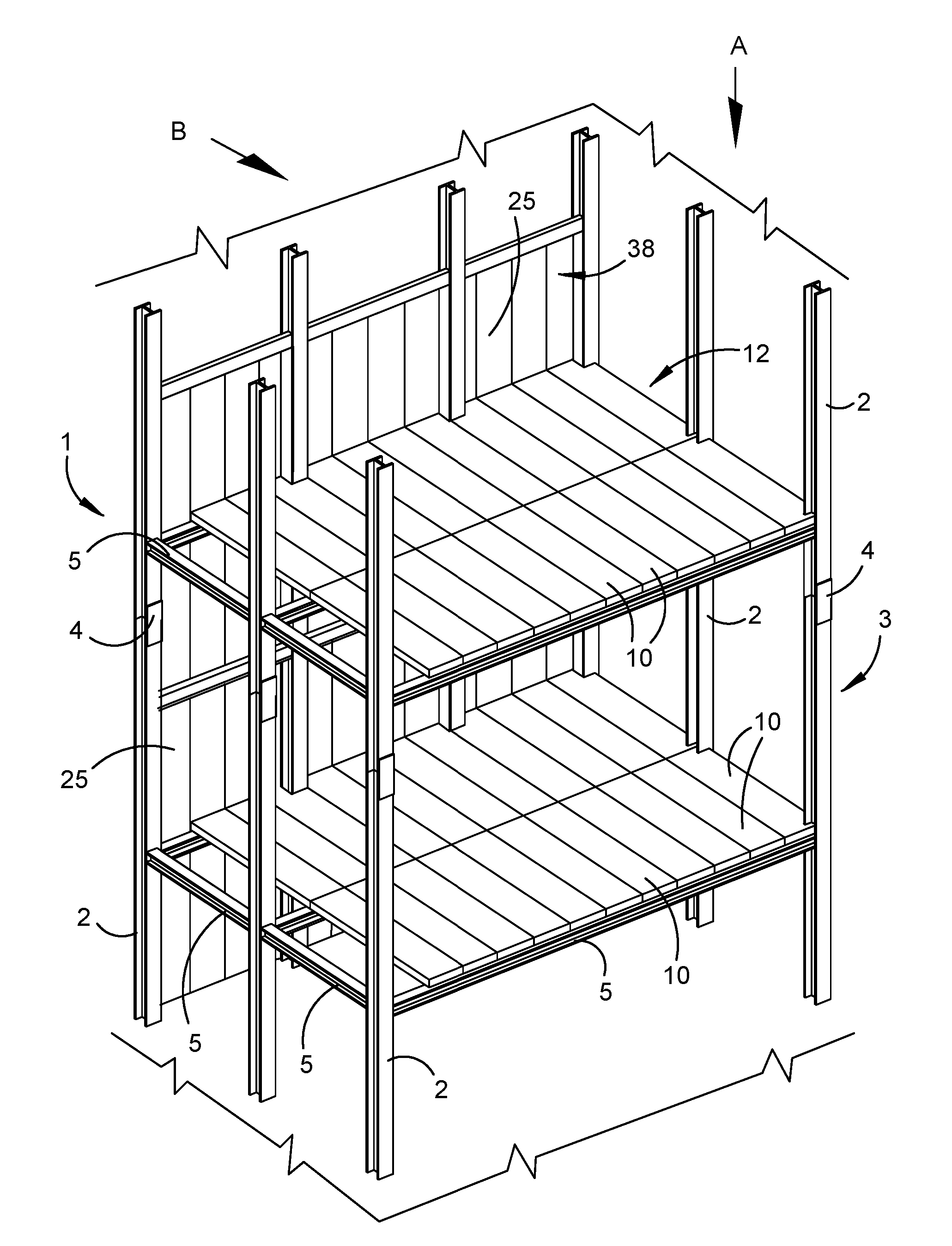

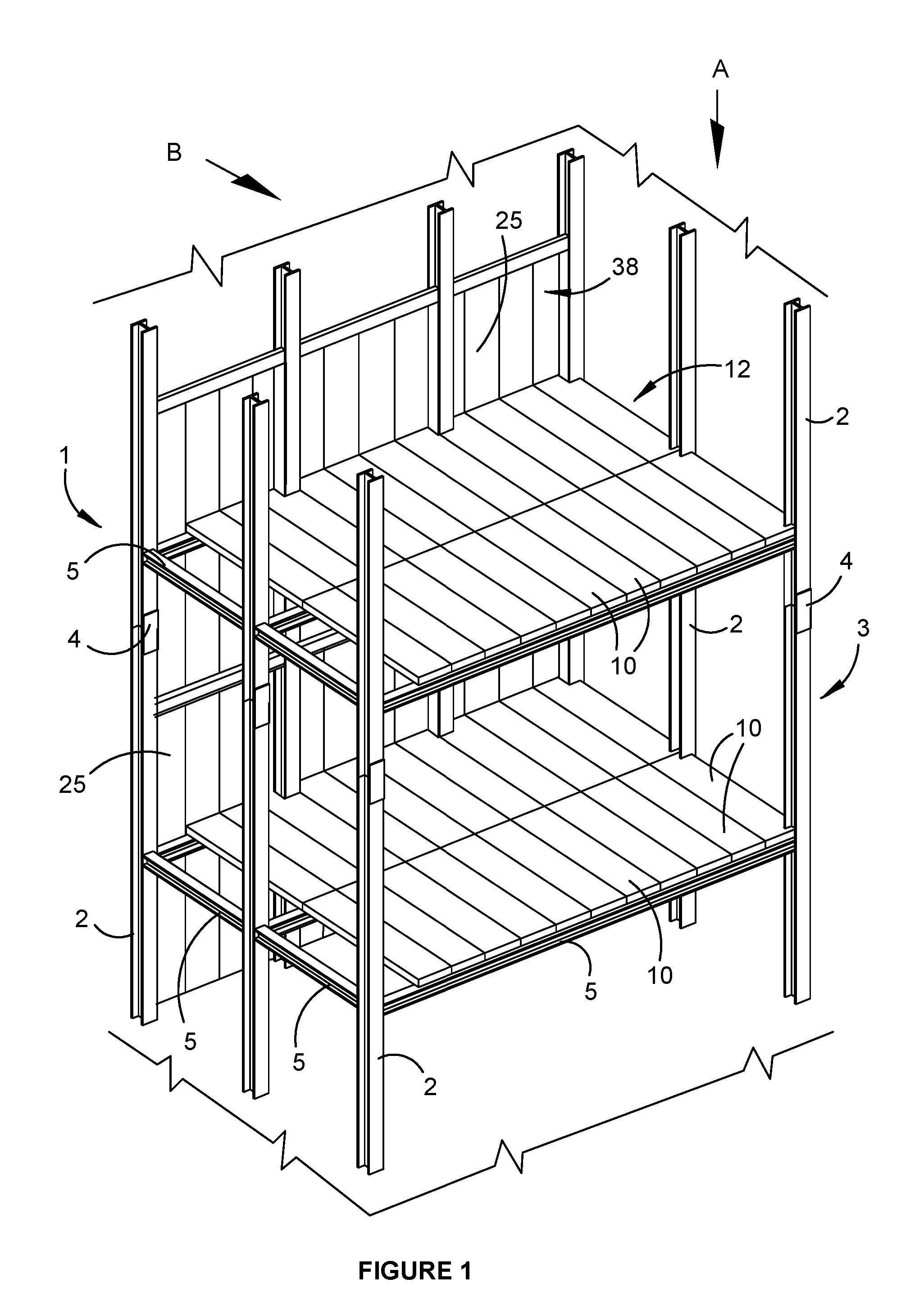

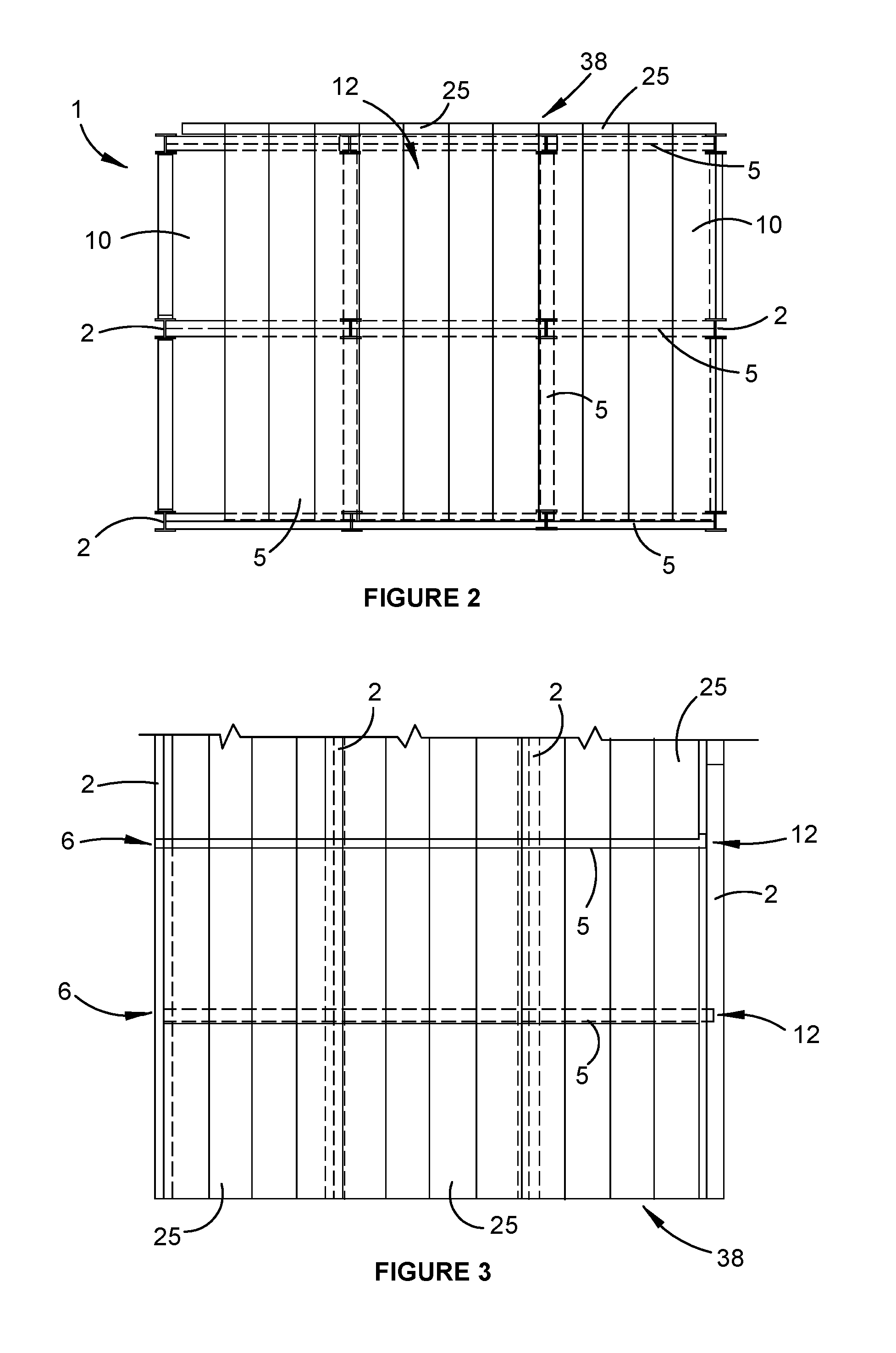

[0107]The invention in one aspect provides a multi-storey building structure 1 and an associated method of construction. Referring initially to FIGS. 1 to 3, the structure 1 includes a series of vertically oriented support columns 2 disposed in spaced apart relationship to define a generally vertical support structure 3. In this embodiment, the support columns 2 are formed from structural steel I-beams, connected end-to-end as required by means of complementary steel connection brackets 4 and associated bolts. However, it should be appreciated that other structural materials, column configurations and interconnection methods may additionally or alternatively be used.

[0108]A series of horizontally oriented floor support beams 5 are connected to the vertical support columns 2 in generally parallel spaced apart relationship, to define a horizontal support structure 6 for an elevated floor. The floor support beams 5 are preferably also formed from structural steel I-beams, bolted or wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com