Downhole cleaning system

a cleaning system and downhole technology, applied in the direction of borehole drives, drilling accessories, borehole/well accessories, etc., can solve the problem of valve blockage, and achieve the effect of simple and easy submergen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

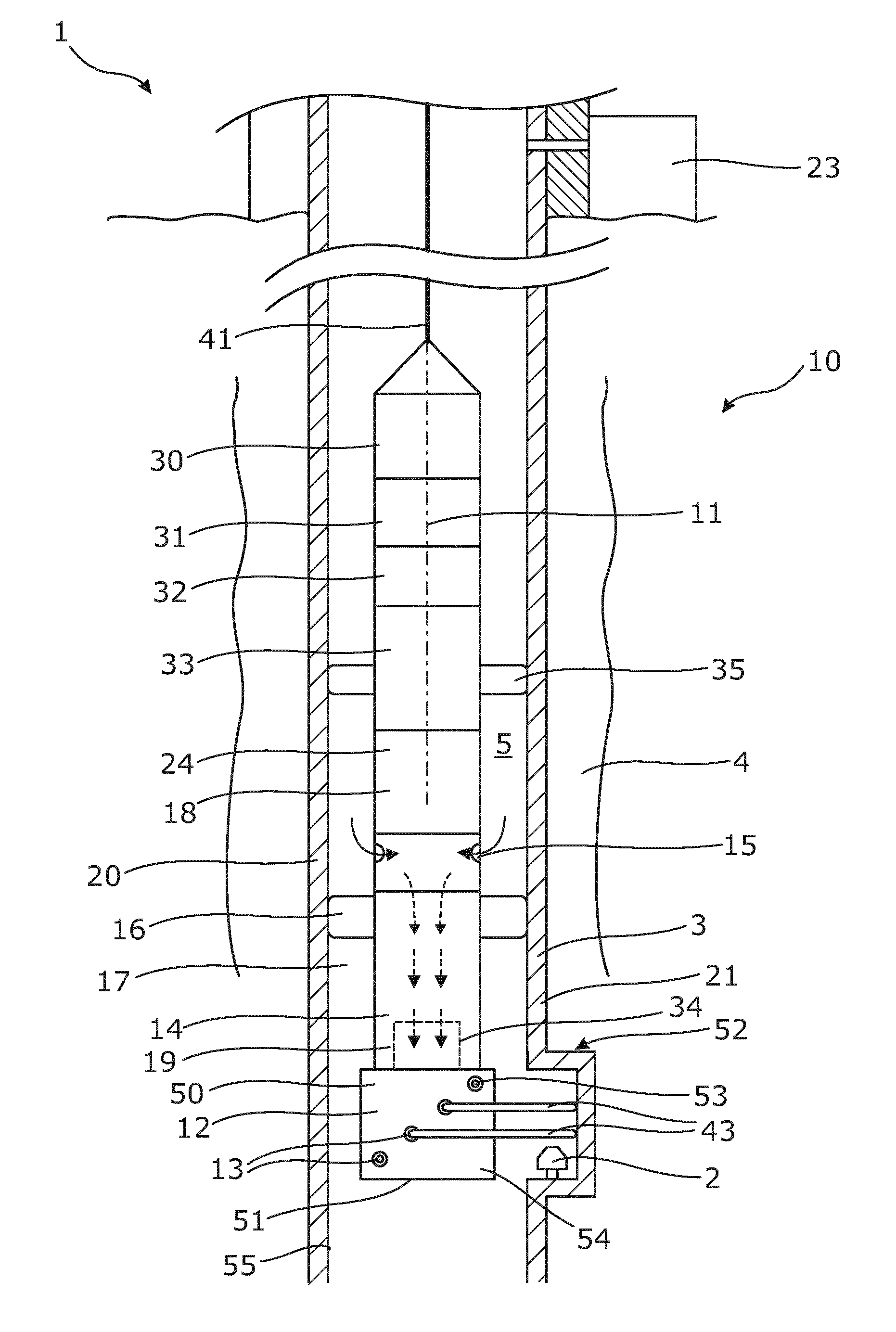

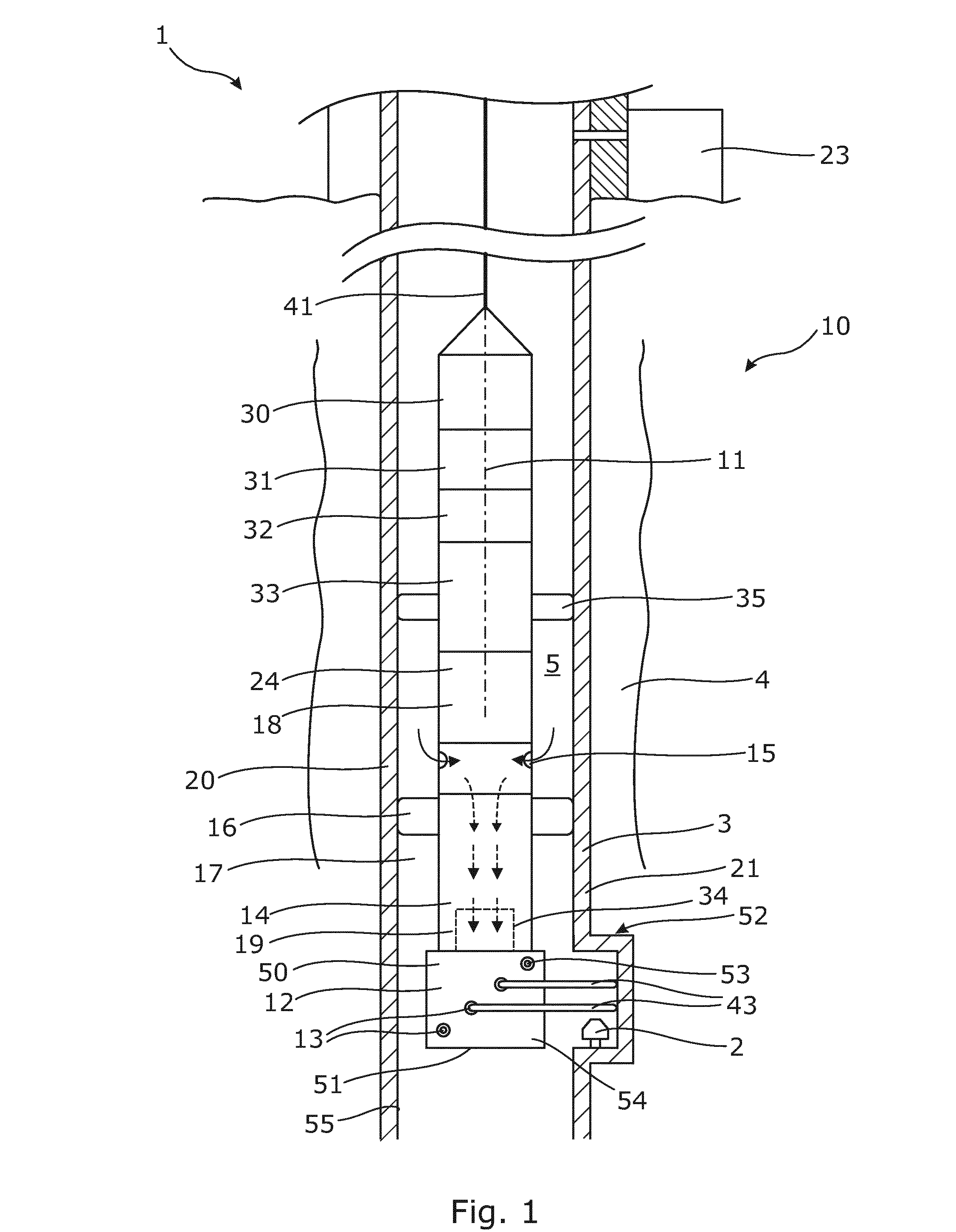

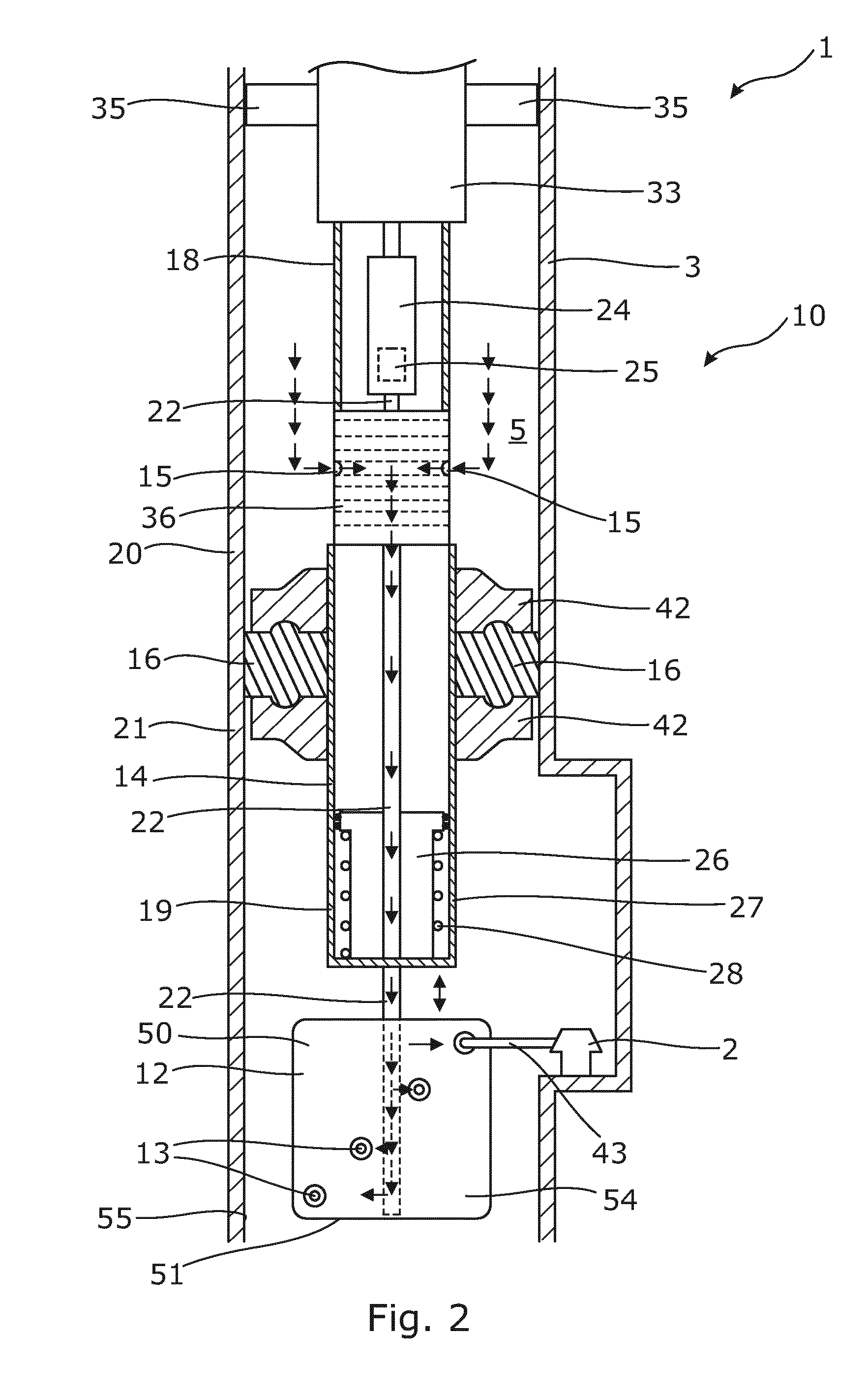

[0072]FIG. 1 shows a downhole cleaning system 1 for cleaning an element 2, such as a gas lift valve (GLV), a sleeve or a side pocket mandrel, in a casing 3 in a wellbore 4 comprising well fluid 5 having a well fluid pressure Pw. The downhole cleaning system 1 comprises the casing 3 and a wireline cleaning tool 10. The wireline cleaning tool 10 has a longitudinal direction 11, and comprises in the end furthest away from the surface a rotatable nozzle head 12 having a plurality of nozzles 13 for cleaning the gas lift valve by jetting high pressurised well fluid out through the nozzles towards the valve.

[0073]By having a cleaning tool or a wireline cleaning tool 10, the cleaning operation can be performed anywhere in the well, also in the more horizontal parts of the well. No landing nipple is required in order to perform a cleaning operation. The system is easy to use and the cleaning tool easily retrieved from the well by pulling in the wireline.

[0074]The wireline cleaning tool 10 ha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap