Imaging Device and Method for Sensing Media Type

a technology of imaging device and media type, which is applied in the direction of digital output to print units, visual presentation using printers, instruments, etc., can solve the problems of difficult to locate and navigate paper setting menus, incorrectly setting media types, and difficult to correctly set media properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

case 2

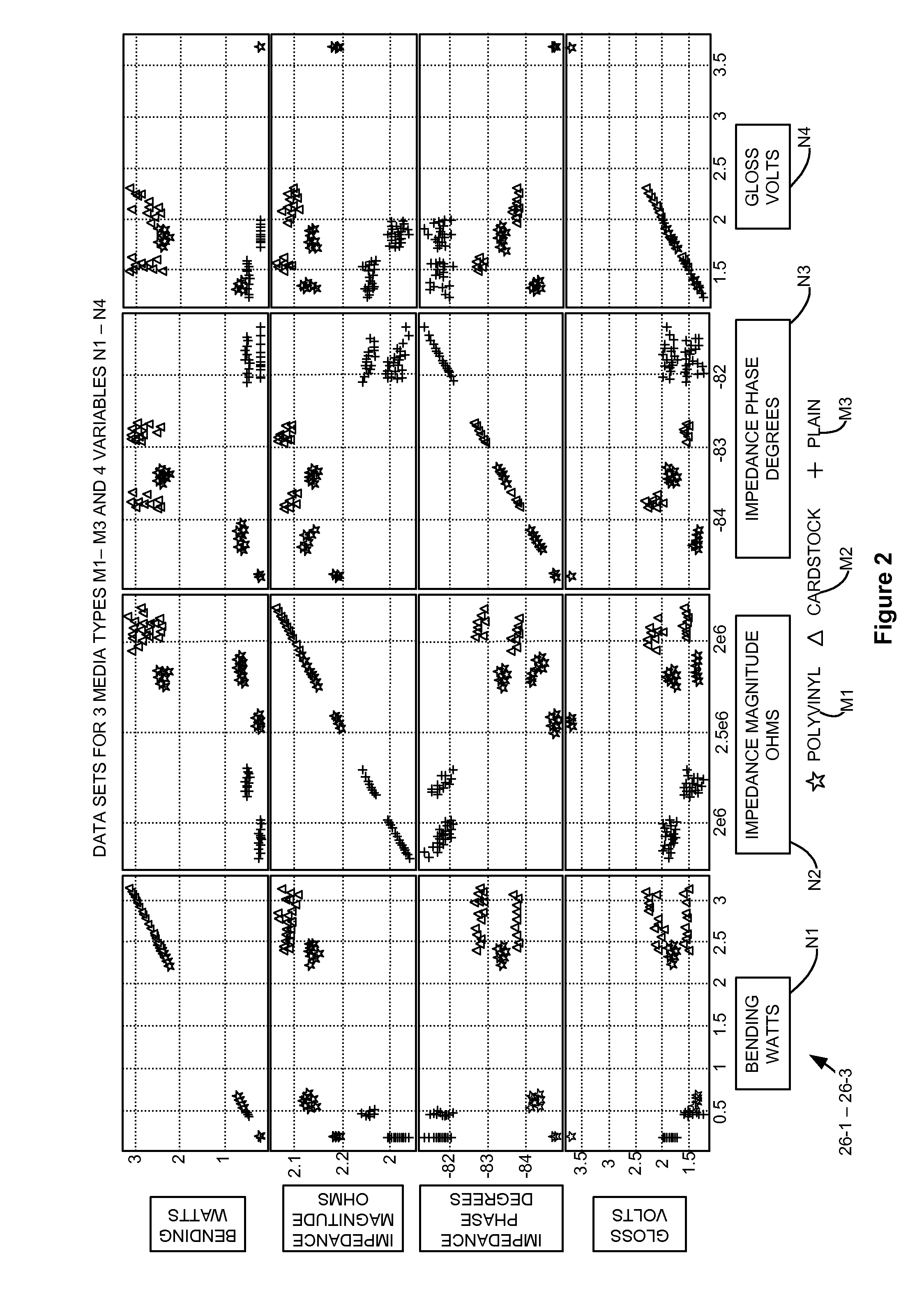

[0114 illustrates the use of direct indirect measurement values and subsystem responses values for determining a second media set consisting of polyvinyl labels, cardstock—all weights, plain paper and lightweight media. Light paper is in the range of 60-75 g / m2 while plain paper is in the range of 75-120 g / m2 (combines standard and heavy plain paper). The measured variables for this case are: Temperature (X1), Relative Humidity (X2), Media Feed Motor Current (X3), Optical Average (X4) and Optical Deviation (X5).

TABLE 7Case 2 Media Type Determining Set - 4 Media TypesEquations Coefficients forMedia Type in Media SetPolyvinylPlainLightEquationLabelsCardstockPaperPaperVariables0.225062−1.424021.0697680.129193X1−0.156180.934353−0.54642−0.23175X2−0.357491.124621−0.30012−0.46701X3−0.234040.1427782.510928−2.41967X40.2477420.121015−2.161721.792964X50.013711−0.026110.213334−0.20093X1*X2−0.03757−0.14570.708307−0.52503X1*X30.029382−0.987021.502796−0.54515X1*X4−0.224861.111549−1.027790.141101X2...

case 3

[0116 represents a media set that would be important to corporate “office” usage: plain paper—all weights, bond paper, cardstock—all weights, polyvinyl labels—all thicknesses, paper labels—all thicknesses, envelopes—all types and transparencies. In this case an extra sensor type, a reflectance sensor has been added such that more information is available to the classifier algorithm to separate the greater number of media types in this case. In Table 8 below, an example of coefficients for each media type and the corresponding sensor term are given. As in the previous case, there is a separate equation for each media type. The number of terms is a function of the number of sensors whereas the number of equations is the number of media types to be classified. The variables (normalized) represent Temperature (X1), Relative Humidity (X2), Impedance Magnitude (X3), Impedance Phase (X4), Reflectance (X5), Optical transmission Average (X6), and Optical transmission variation (X7). Reflecta...

case 4

[0120 illustrates an imaging device which is designed to be useful for a wide variety of tasks. This system will classify the following paper types: plain paper light; plain paper standard; plain paper heavy; cardstock light; cardstock heavier weight—165-300 g / m2 (combined standard and heavy weight cardstock); glossy paper—all weights; paper labels—all thicknesses; polymer (vinyl) labels—all thicknesses; envelopes—all types; polymer signage; transparencies; and bond paper.

[0121]For Case 4 the training sensor set includes: Temperature (X1), Relative Humidity (X2), Impedance Magnitude (X3), Impedance Phase (X4), Reflectance (X5), Media Feed Motor Current (X6), Optical transmission Average (X7), and Optical transmission Variation (X8). As in earlier cases each media type to be classified has an equation. Here there are 165 terms in each equation and eleven equations in the media type determining equation set 40. These equations are broken into Table 10 and Table 11 due to the large num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com