Apparatus for modeling three-dimensional object and method for modeling three-dimensional object

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

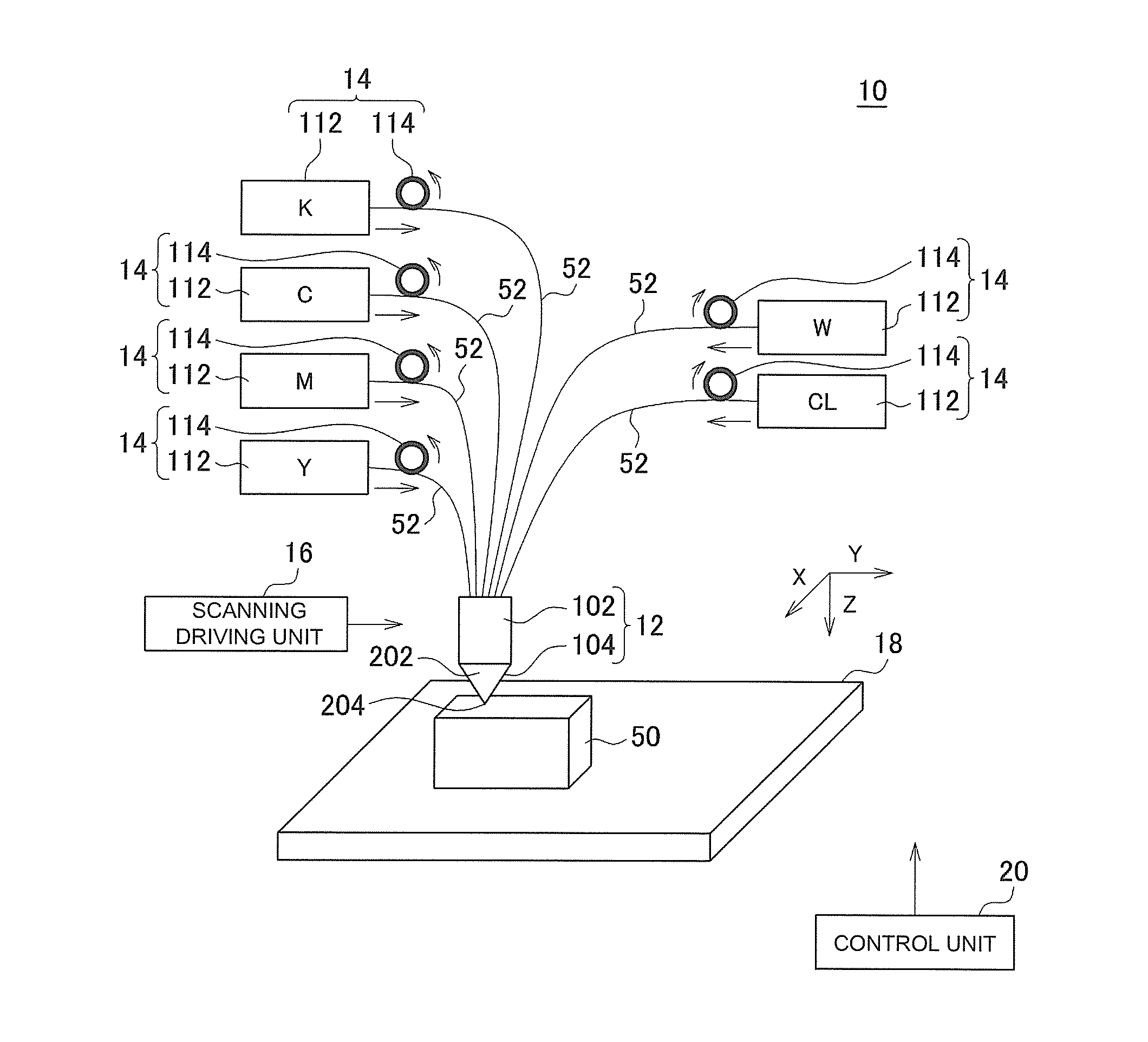

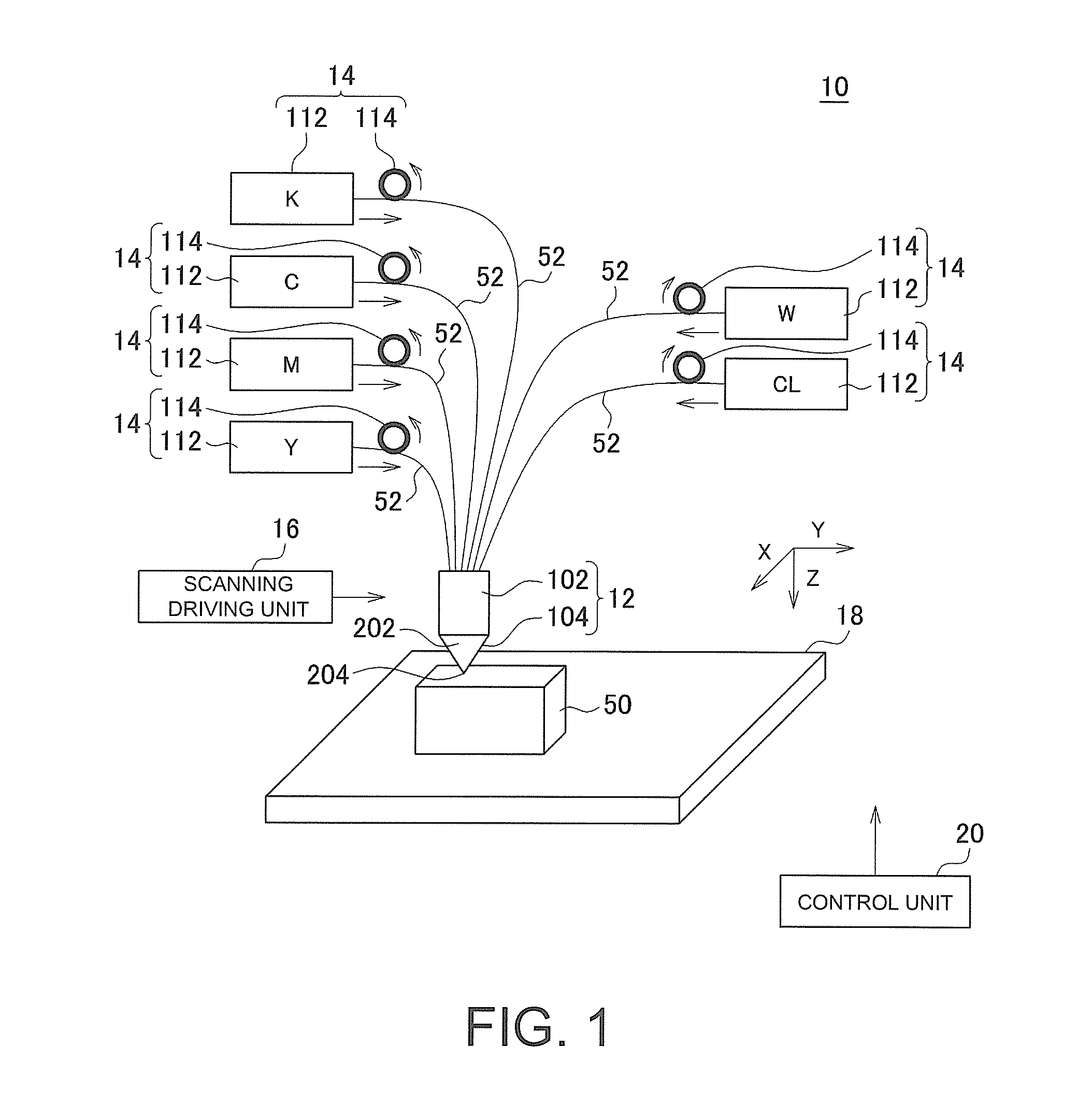

[0031]Hereinafter, an illustrative embodiment of the disclosure will be described with reference to the drawings. FIG. 1 depicts an example of an apparatus 10 for modeling a three-dimensional object according to an illustrative embodiment of the disclosure. In this illustrative embodiment, the apparatus 10 for modeling a three-dimensional object is an apparatus for modeling a three-dimensional object configured to model a three-dimensional object by a fused deposition modeling method. In this case, the fused deposition modeling method is a method of extruding resins, which are fused by the heating, from nozzles and depositing the same to model a three-dimensional object.

[0032]More specifically, the apparatus 10 for modeling a three-dimensional object is configured to perform the modeling by using a filament, which is a thread-shaped or fine line-shaped resin, as a material resin that is a resin to be used as a modeling material. Also, the apparatus 10 for modeling a three-dimensiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Color | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com