Anti-spalling body armor protection system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

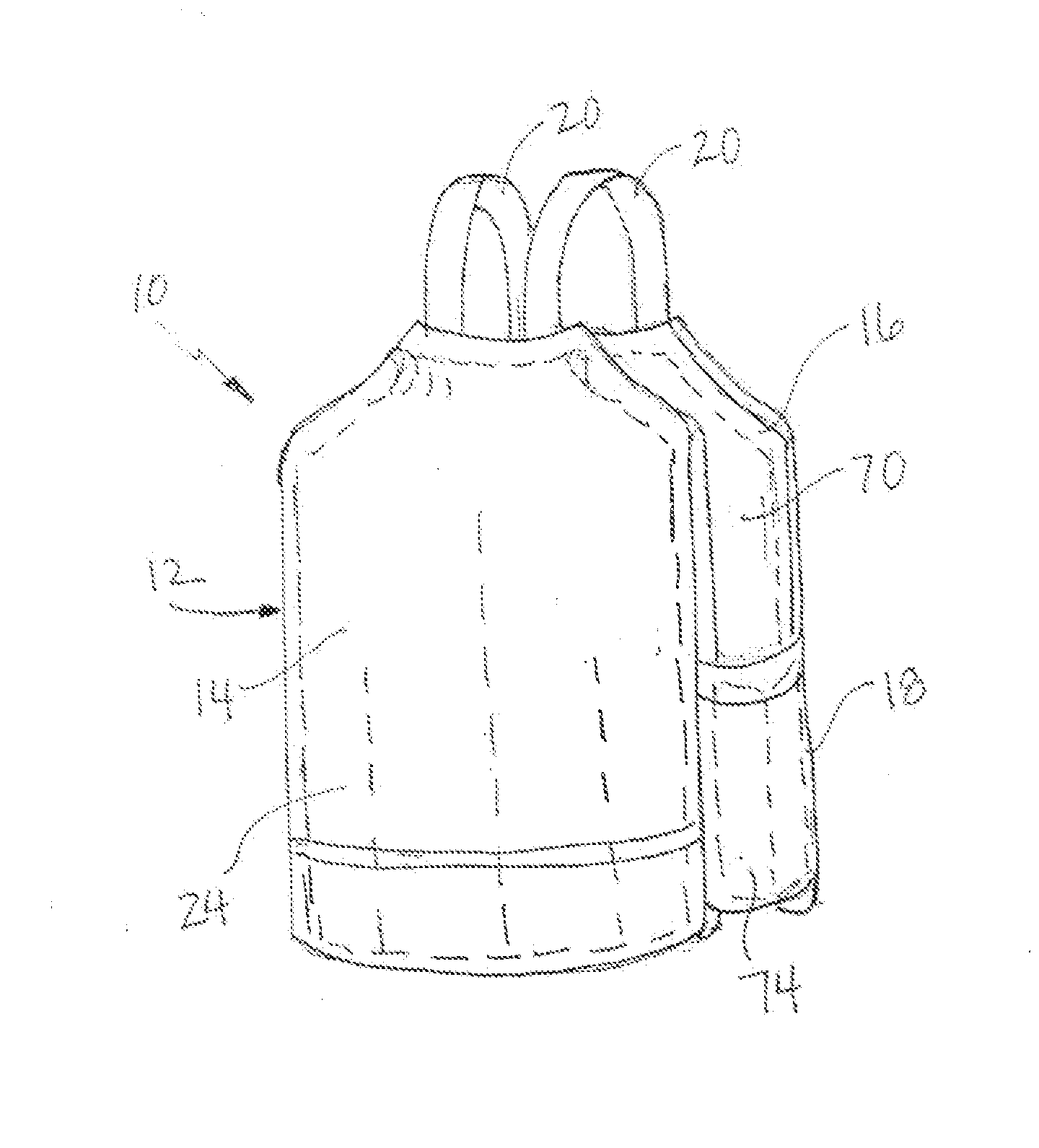

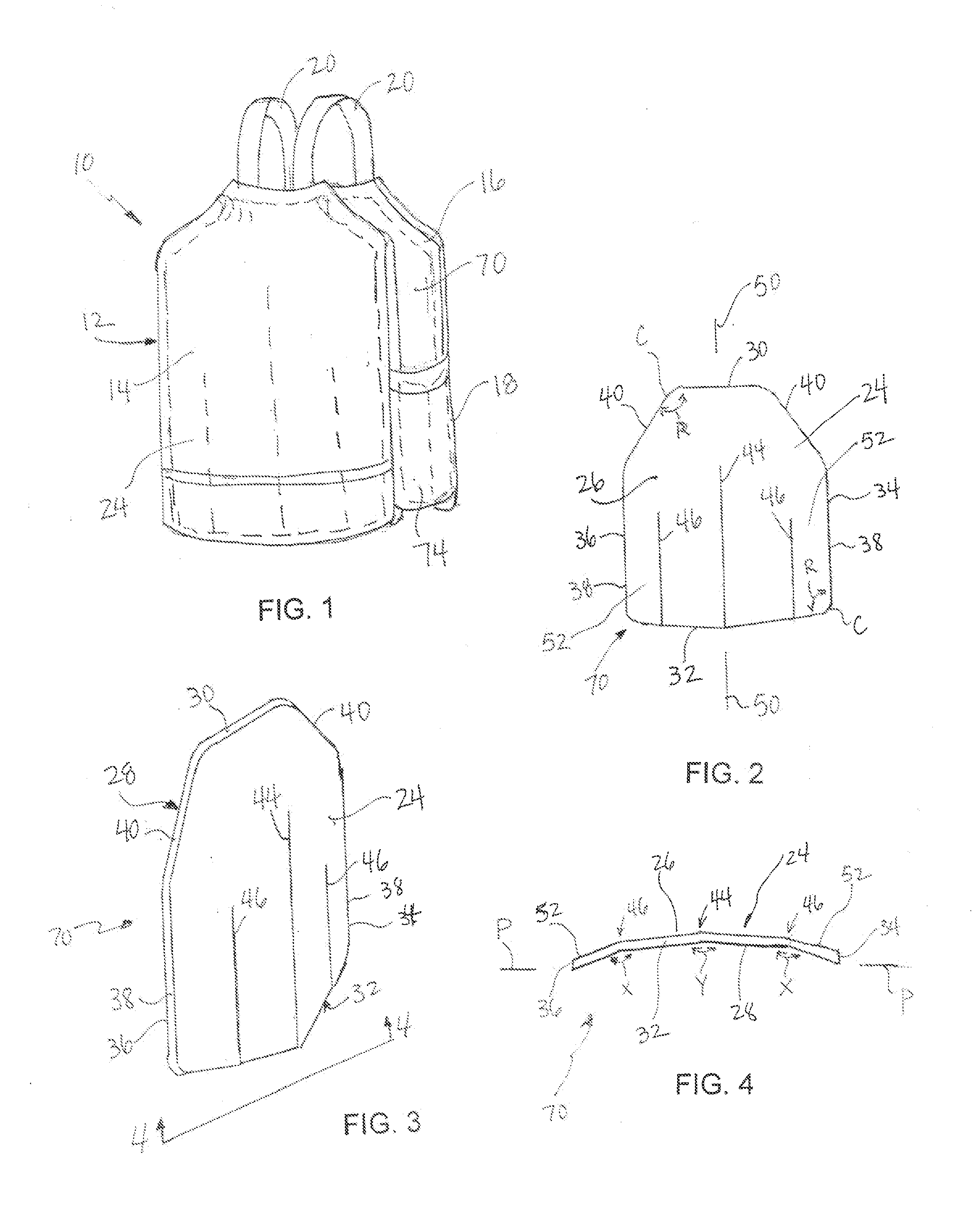

[0052]FIG. 1 illustrates but one type of protective apparatus that may be worn on a person's or animal's body to protect the wearer from bullet- or small-arms fire. Such protective apparatus are generally structured to cover, in a human, the chest and back area, and the sides or lateral margins of a person's torso. Protective apparatus are commonly known and referred to as bulletproof jackets or flak jackets, or any other number of names or terms, all of which are relevant to the present disclosure. Therefore, reference to or illustration of a single type of protective apparatus is not meant to be limiting of the disclosure. The arrangement of FIG. 1 merely illustrates a simplified form of a protective apparatus that provides ease of illustration of the inventive disclosures herein, and the armor plate arrangements of the anti-spalling body armor system can be adapted to any type, form or configuration of outer carrier device or jacket.

[0053]In FIG. 1, a body armor system 10 is show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

| Resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap