Actuator assembly for a pressurized plastic vessel

a technology of actuators and plastic vessels, applied in the direction of packaging, liquid dispensing, transportation and packaging, etc., can solve the problems of difficult, if not impossible, to stand the plastic vessel on a substantially flat surface, difficult to wipe clean and keep sanitary, and difficult to securely attach, hold, detach and re-attach relatively small actuators. , to achieve the effect of reducing the overall time and cost, increasing the cost, time and machinery, and reducing the overall cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

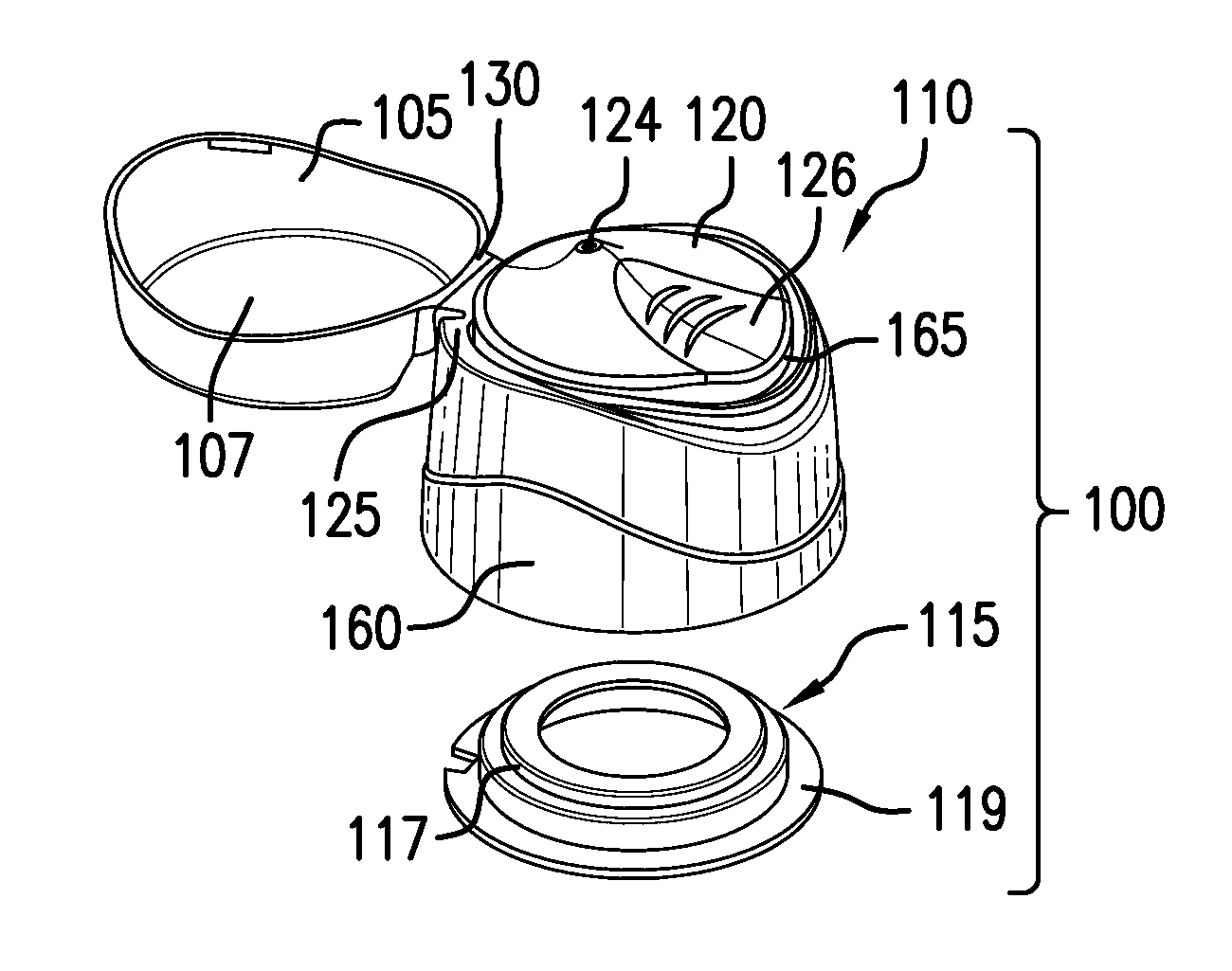

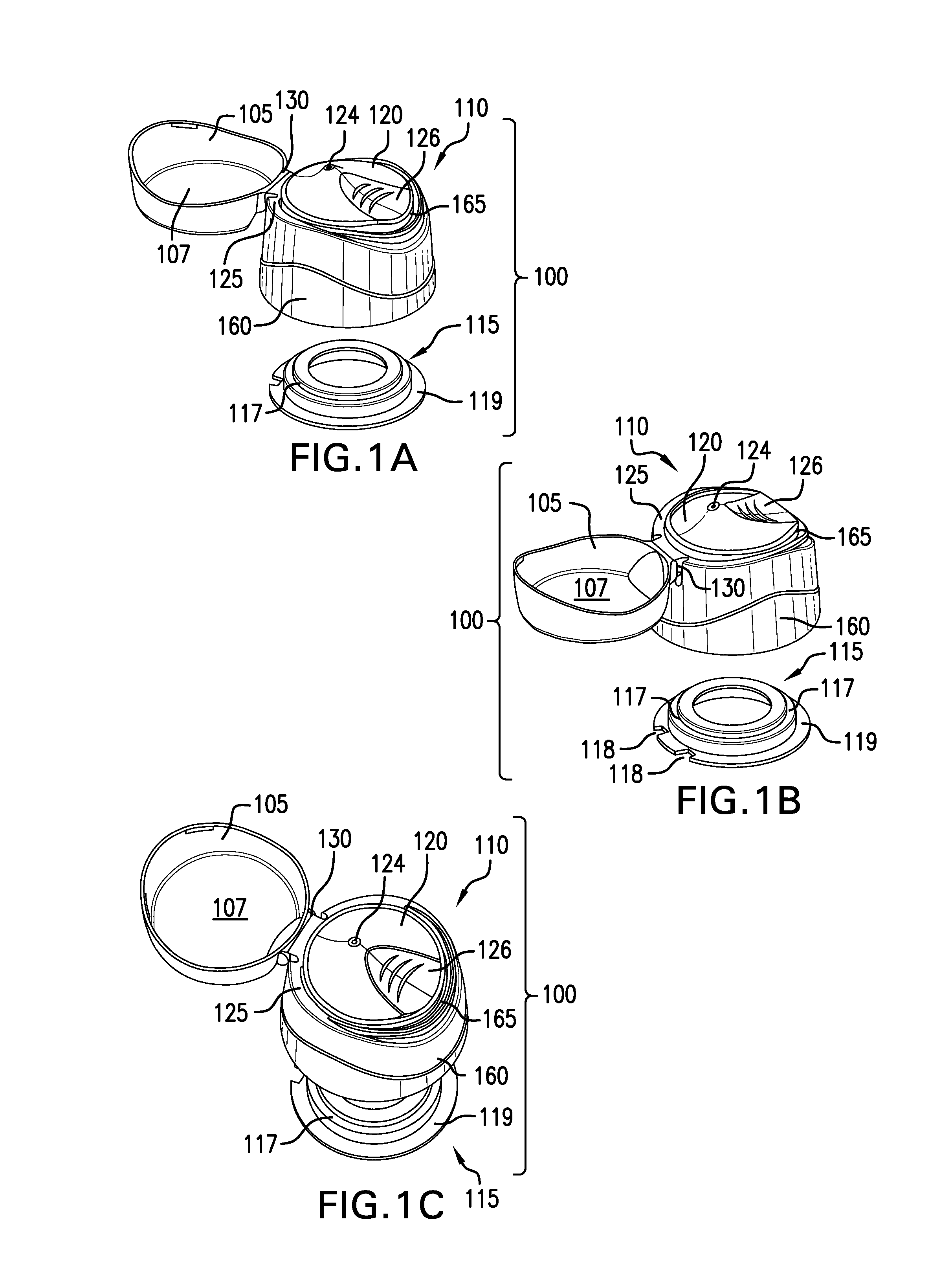

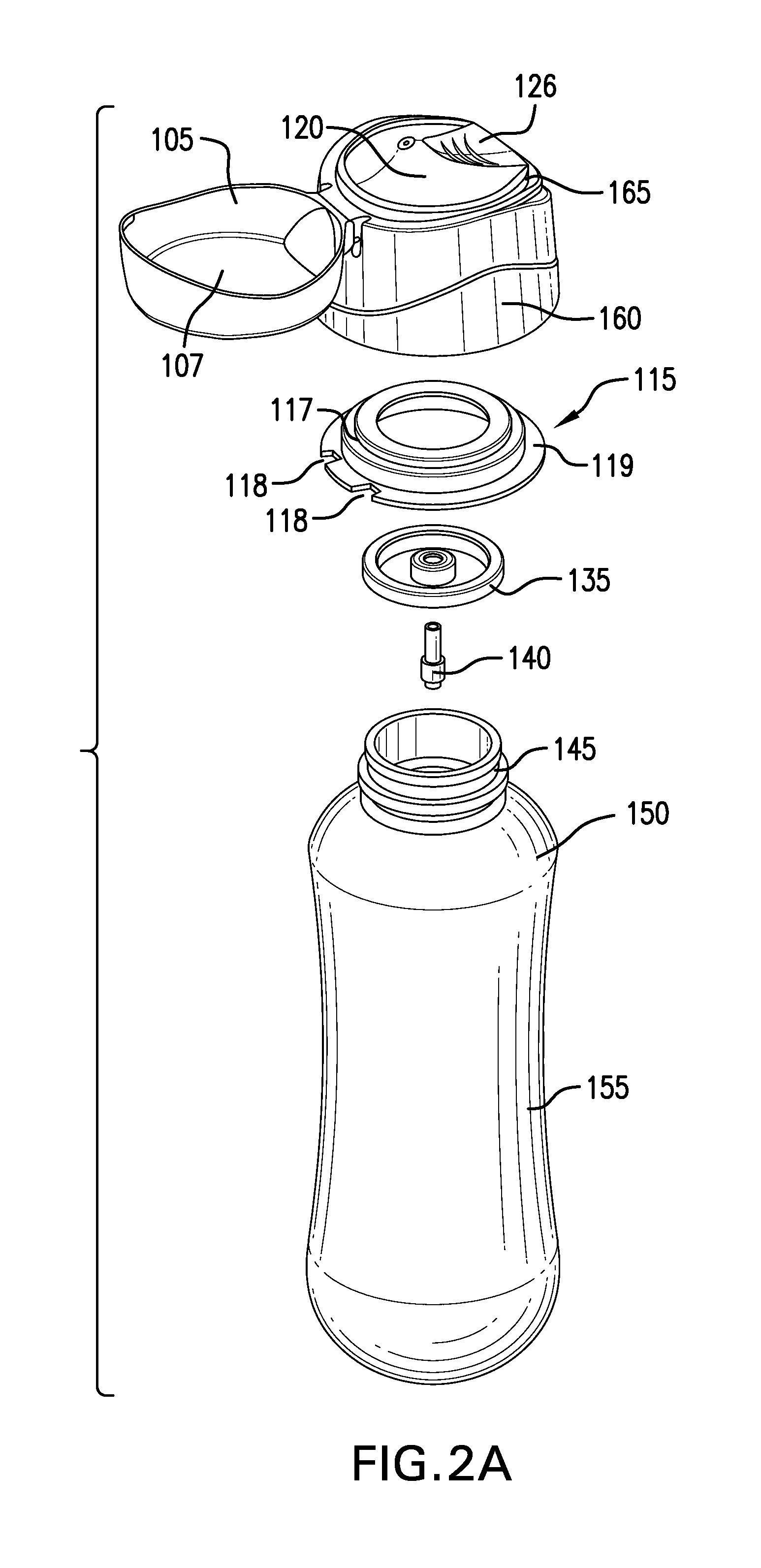

[0040]FIGS. 1A, 1B and 1C show, respectively, a front-left perspective view, a rear-left perspective view, and a top-left perspective view of an two-piece oversized actuator assembly 100, in accordance with an exemplary embodiment of the present invention, with the flip-open undercap 105 in the open position. FIGS. 2A and 2B show exploded views of the two-piece oversized actuator assembly 100, along with the valve cap 135, pressure valve 140 and plastic vessel 155, as seen from a rear-left perspective and a front-left perspective, respectively. Thus, FIGS. 2A and 2B illustrate the relative sizes and positions of the components of the actuator assembly 100 in relation to a typical valve cup 135, pressure valve 140 and pressurized plastic vessel 155. FIG. 3A shows is a left side exploded view of the two-piece actuator assembly 100 further illustrating the relative positions of the actuator body 110, adaptor 115, valve cup 135, pressure valve 140 (also known as a valve stem) and plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com