Internal reinforcement and confinement structure for warheads

a technology of confinement structure and warhead, which is applied in the direction of projectiles, weapons, ammunition projectiles, etc., can solve the problems of significant design, performance and safety problems, additional problems, and reduce the effectiveness of the warhead, so as to efficiently deliver the warhead payload to the target, maintain the integrity of the warhead, and minimize collateral damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

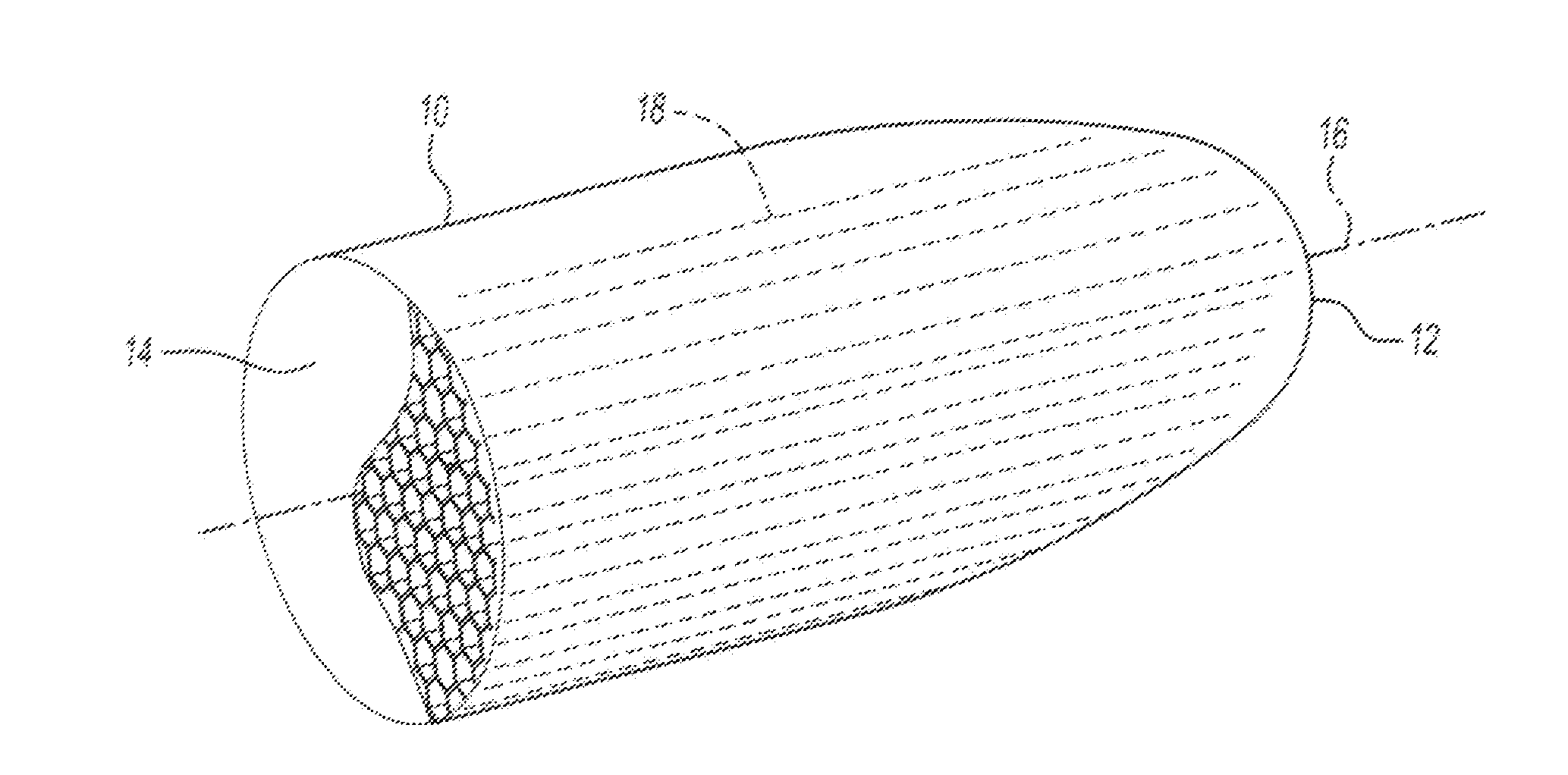

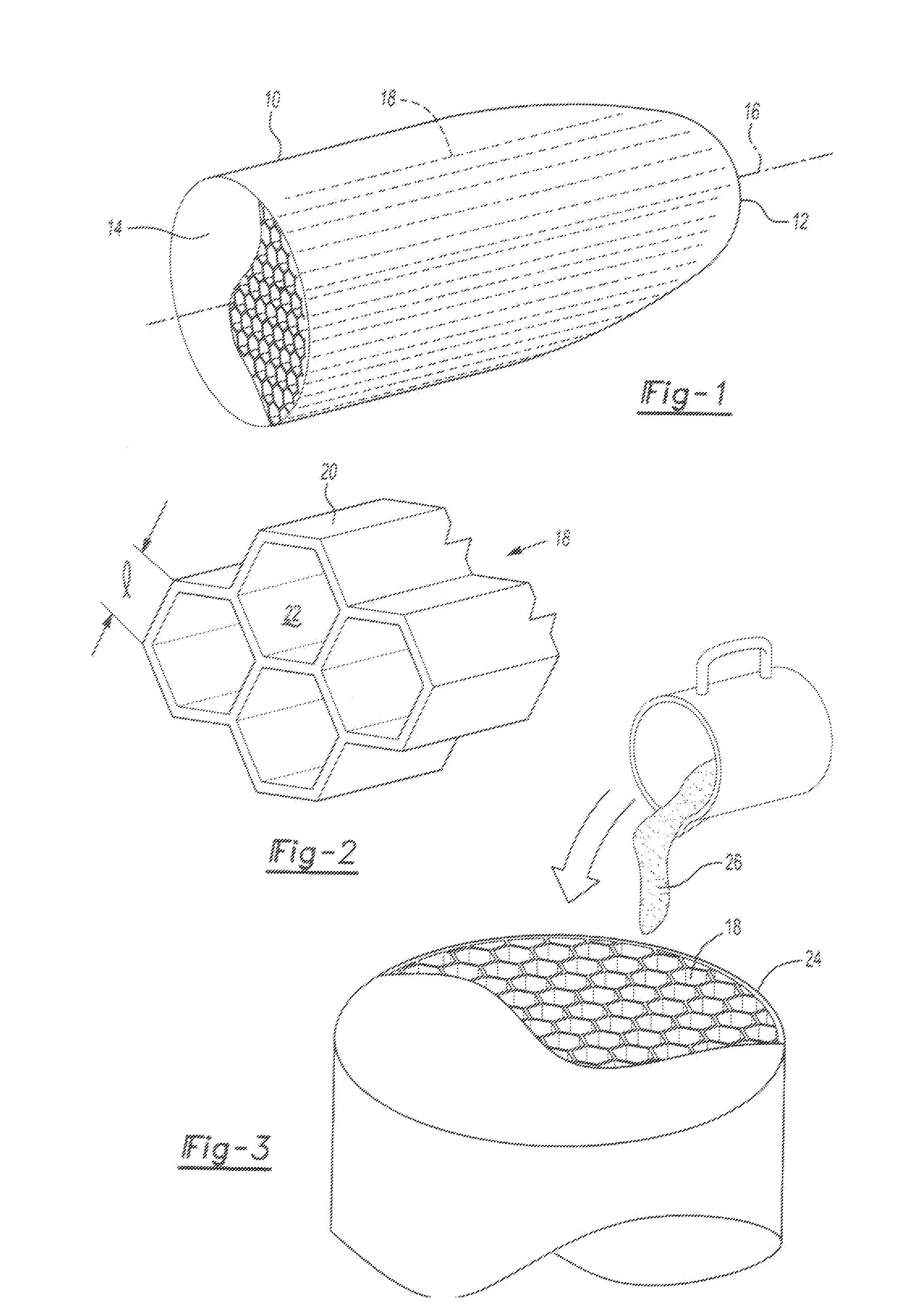

[0020]With reference first to FIG. 1, an exemplary warhead 10 is shown having both a front end 12 and a base end 14. The warhead 10 is adapted to be gun launched along a launch axis 16 from a gun toward the target.

[0021]With reference now to FIGS. 1 and 3, the warhead 10 includes a support structure 18 positioned within a tubular and cylindrical outer wall 24 of the warhead 10. The support structure includes a plurality of chamber (cell) walls 20 which, together, form a plurality of chambers 22 each of which is elongated in the direction of the launch axis 16. Each chamber 22, furthermore, is a closed chamber and thus isolated from its adjacent chambers 22 by the chamber (cell) wall 20. Preferred embodiments of the present invention do not require multipoint detonation. Thus, each chamber or at least a majority of the chambers should have a cross section greater than the critical detonation cross section area required for stable, sustainable detonation of the explosive contained wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com