Multi-needle quilting machine and corresponding quilting method

a multi-needle, quilting machine technology, applied in the direction of sewing machine elements, mattress sewing, textiles and paper, etc., can solve the problems of distorted geometries, deformation or curling of materials being worked, and compromise the correct execution of stitches, so as to achieve clean, precise and linear cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

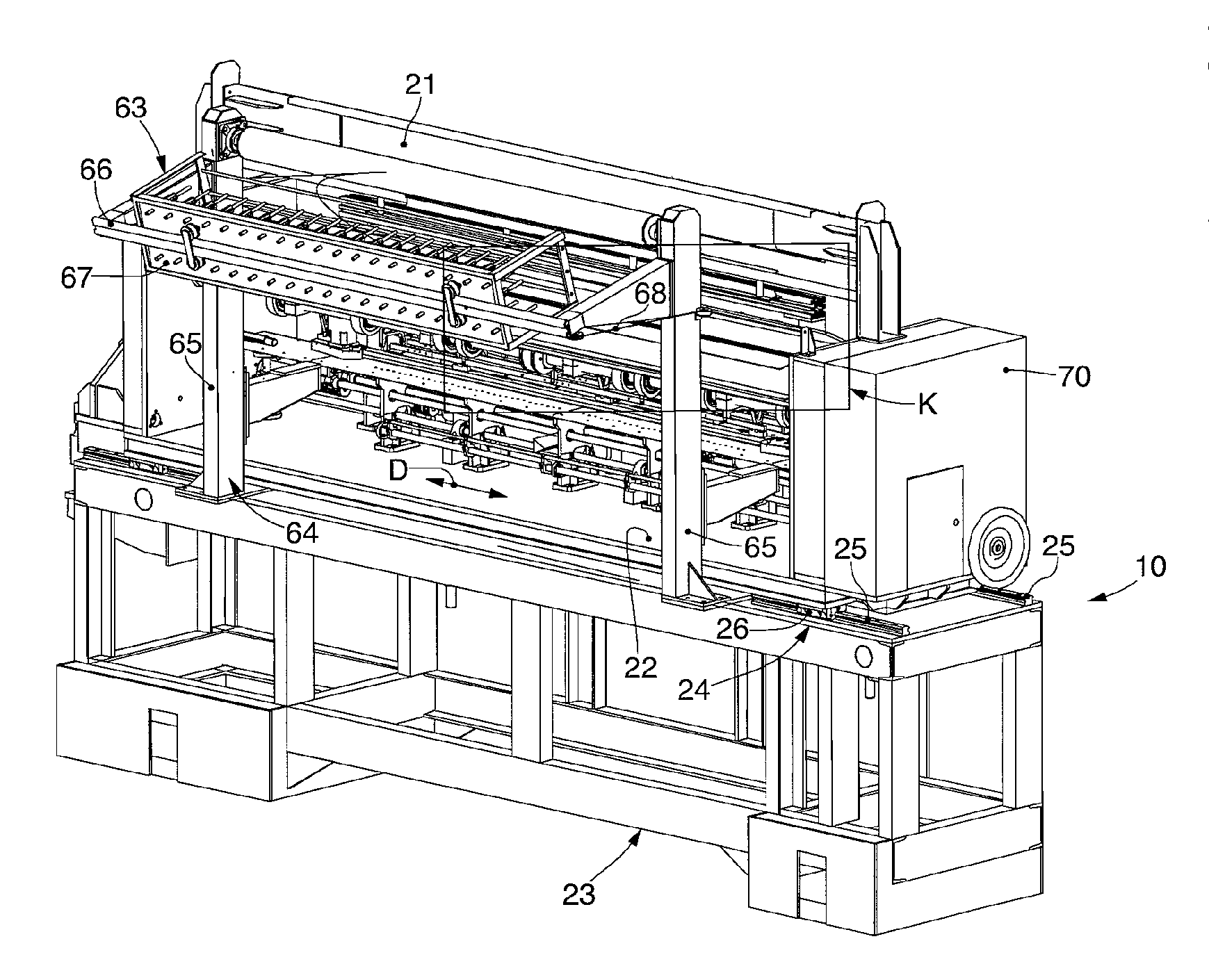

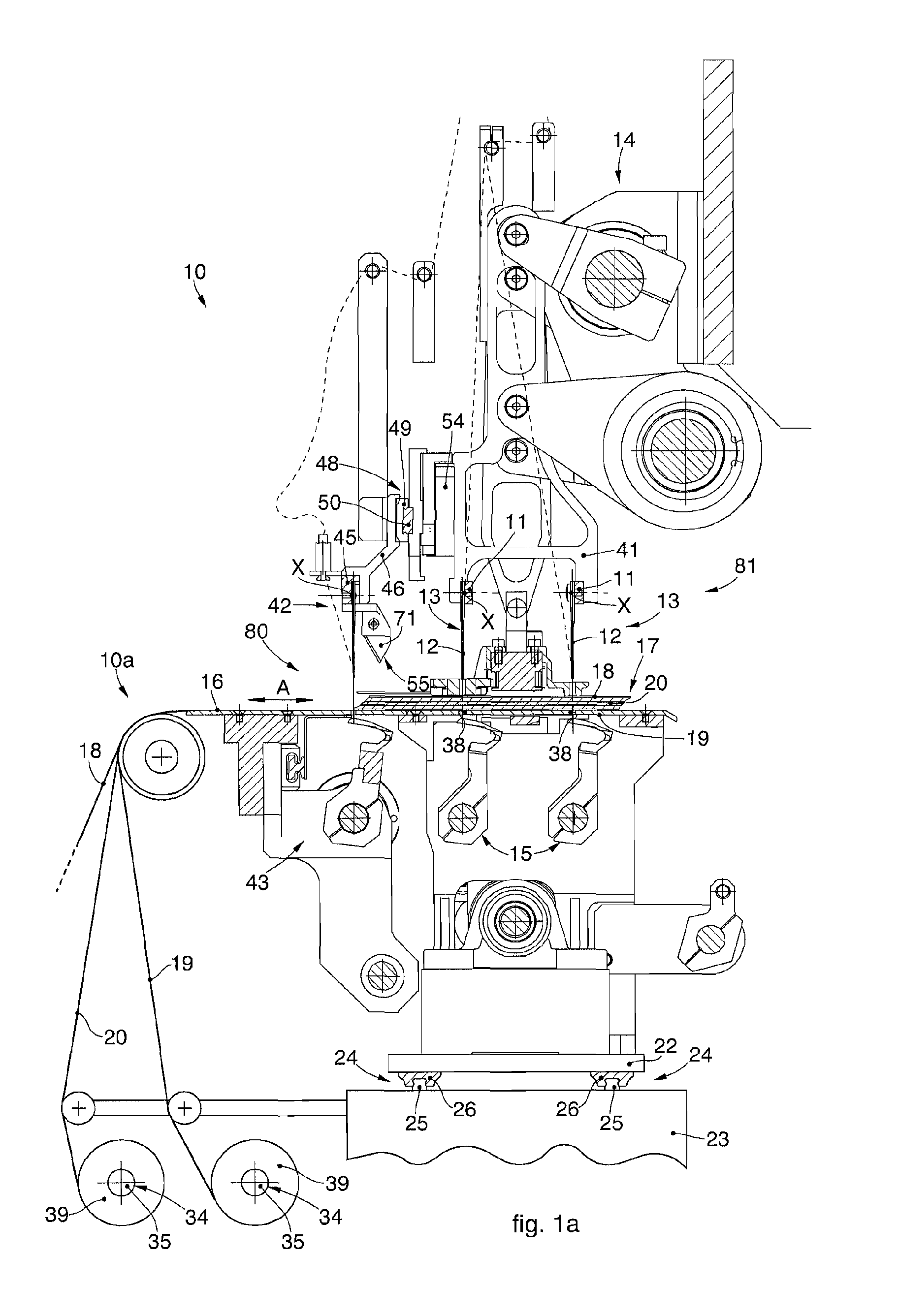

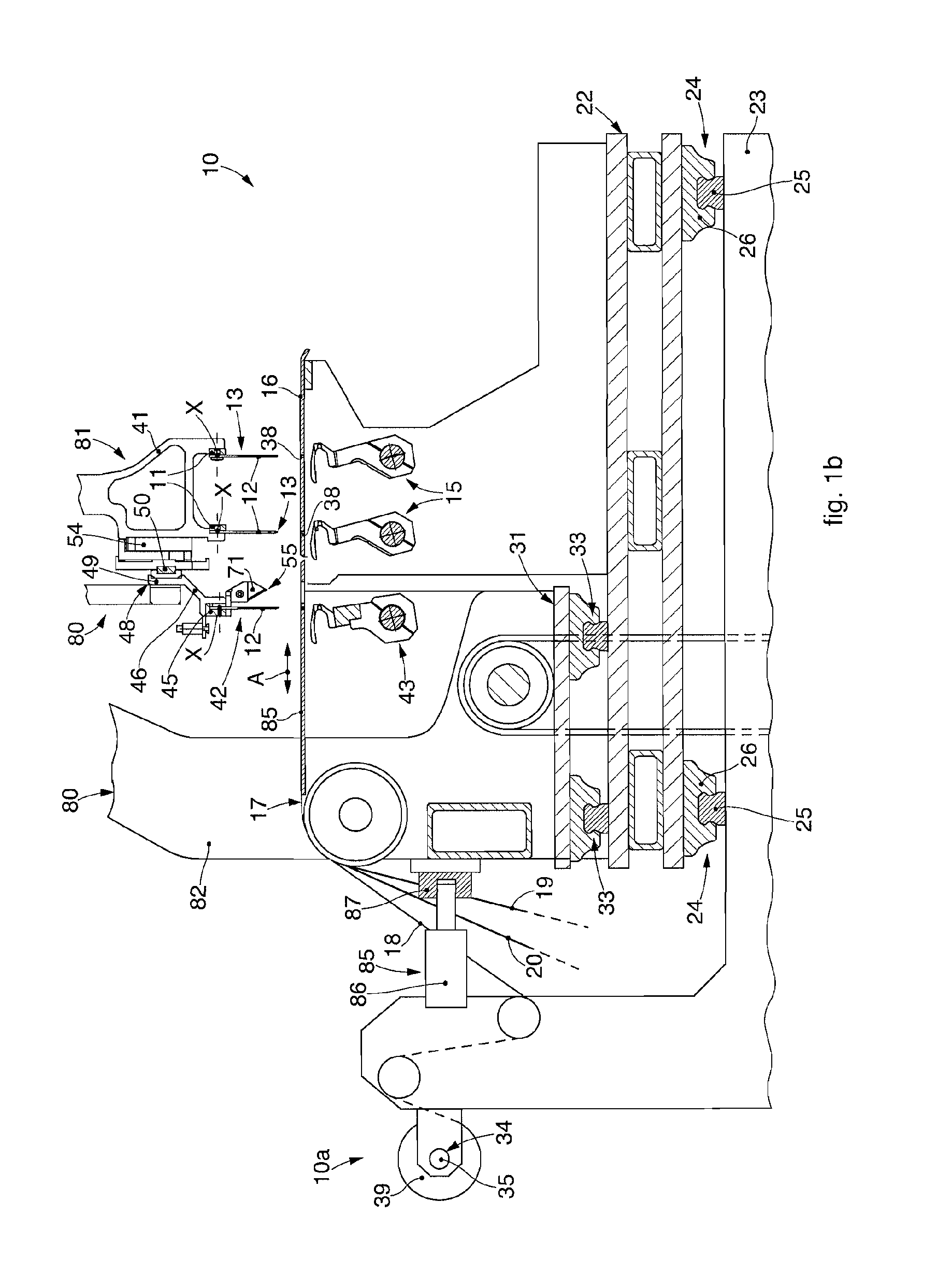

[0071]FIGS. 1a, 1b, 1c and 1d each represent schematically a quilting machine 10 comprising a base 23, at least a first platform 22, a first stitching unit 80, in this case with only one row 42 of needles 12, and a second stitching unit 81, in this case with two rows 13 of needles 12.

[0072]In each row 13 or 42, the needles 12 are disposed substantially aligned along a respective longitudinal axis X located substantially orthogonal to a direction of feed A in which the material to be quilted 17 is fed.

[0073]The rows 42 and 13 of needles 12, also called hereafter auxiliary upper stitching members 42 and respectively upper stitching members 13, cooperate in use with corresponding auxiliary lower stitching members 43 and respectively lower stitching members 15 in order to make the stitches.

[0074]The auxiliary lower stitching members 43 and the lower stitching members 15 can comprise either a shuttle, a rotary crochet, a mobile hook (the latter shown for example in FIGS. 1a, 1b, 1c and 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com