Active self-transformable textiles

a self-transformable, textile technology, applied in the field of active self-transformable materials, can solve the problems of complex methods and technologies, high cost, and high labor intensity, and achieve the effect of reducing labor intensity, reducing labor intensity, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

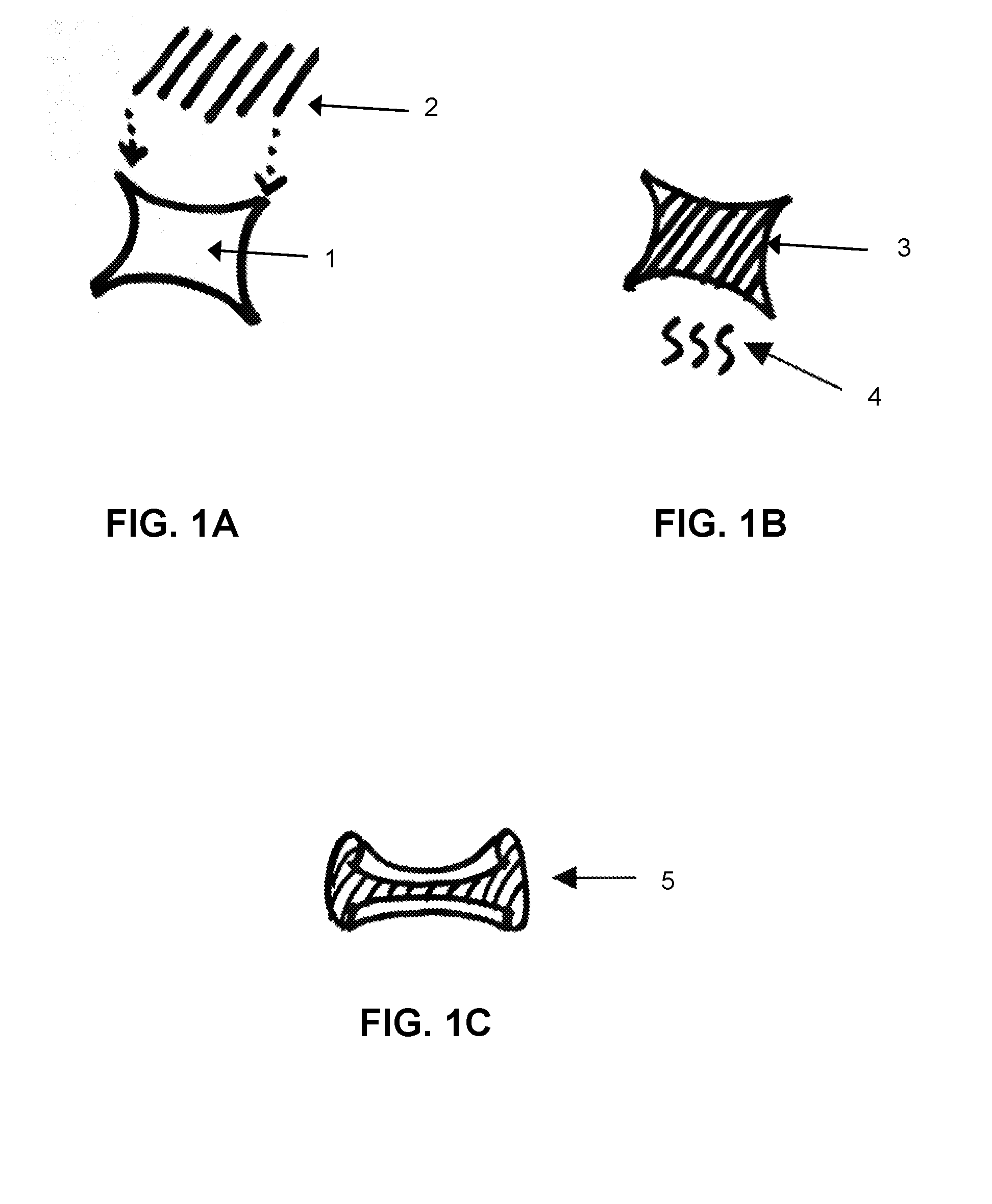

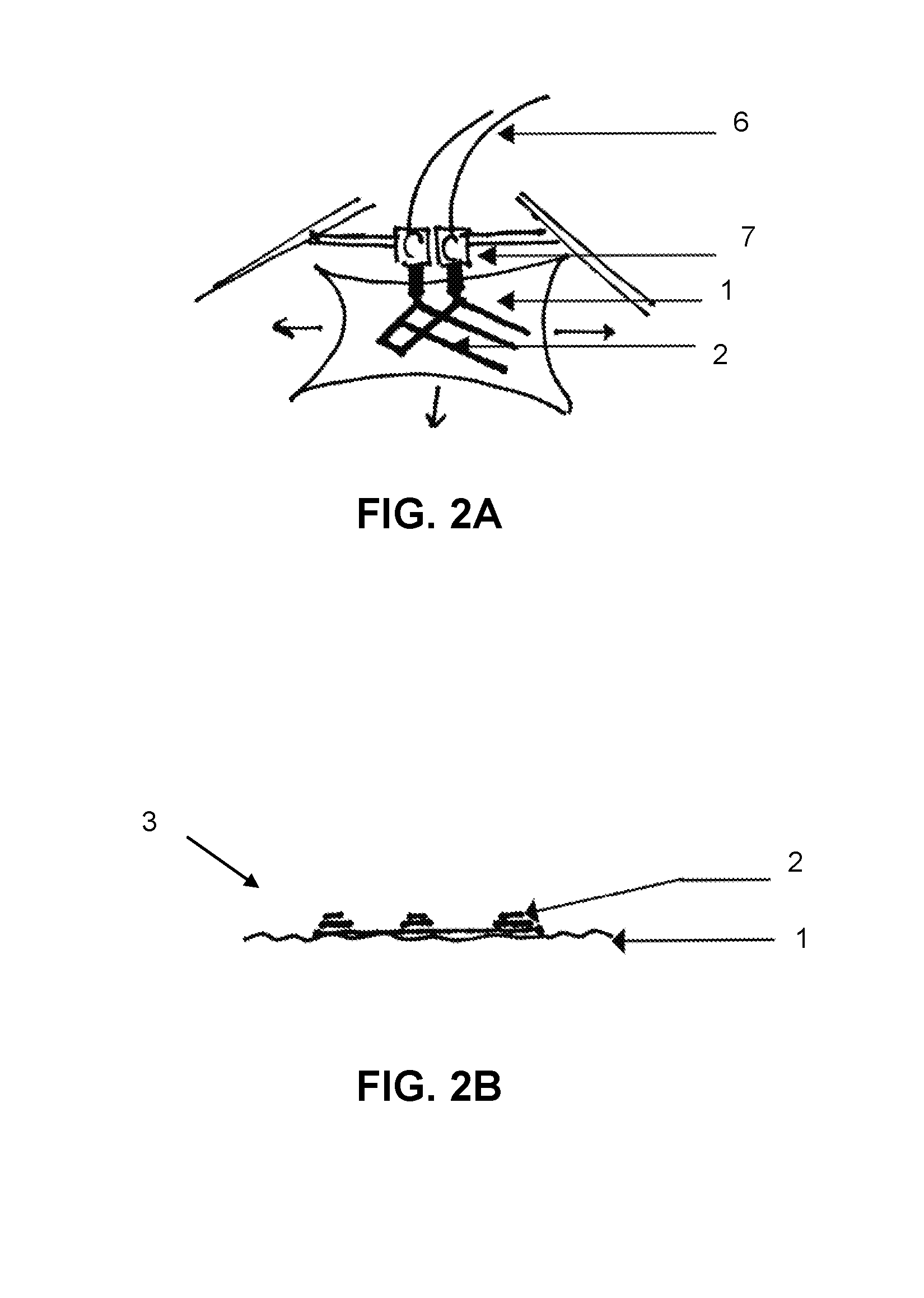

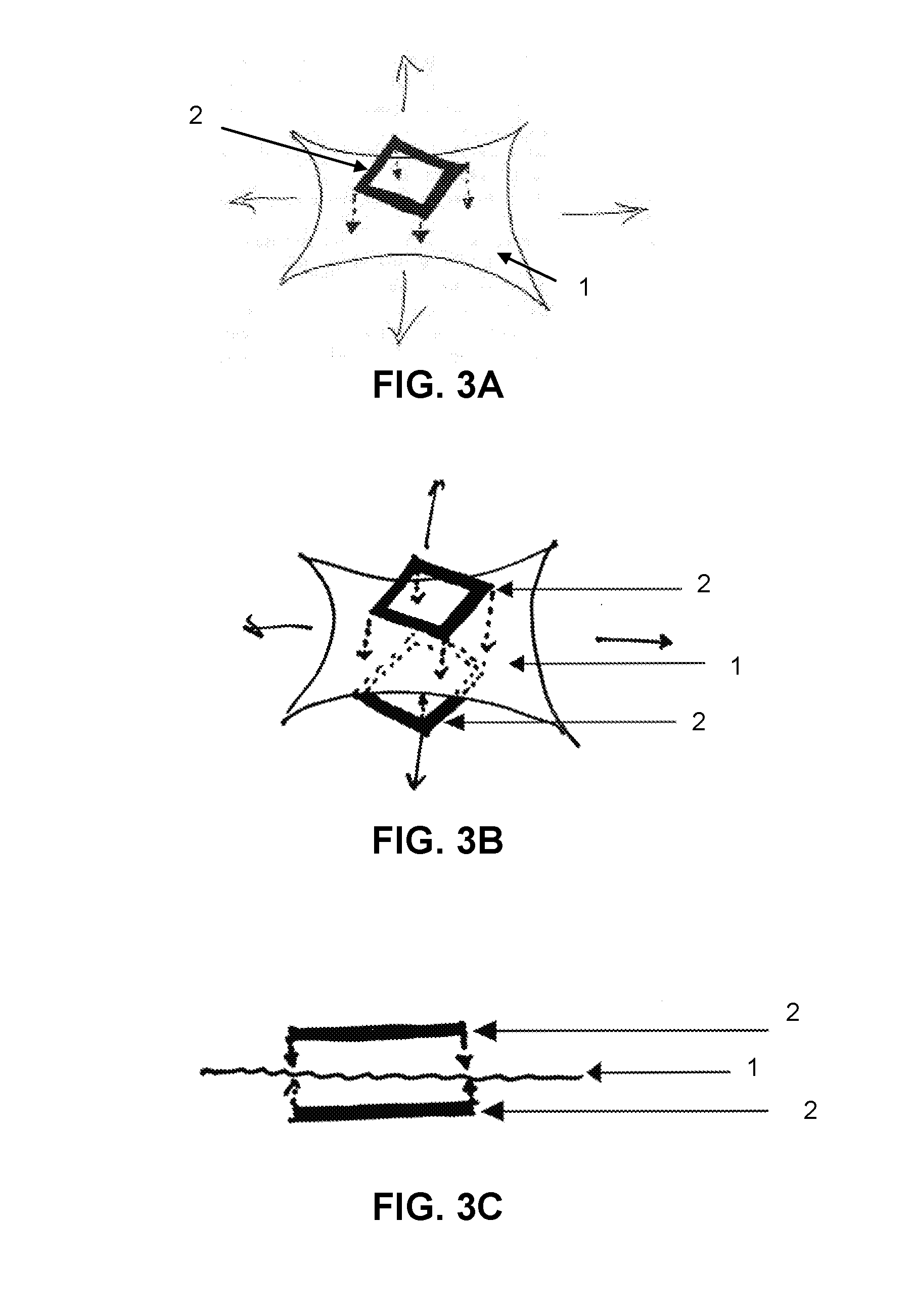

Method used

Image

Examples

Embodiment Construction

[0025]The following definitions are useful for interpreting terms applied to features of the embodiments disclosed herein, and are meant only to define elements within the disclosure.

[0026]As used herein, the term “manufactured shape” or “transformed shape” refers to a predetermined geometrical shape. For example, according to the present invention, a manufactured or transformed shape is different than a shape that would occur in the flexible base material absent application of the active material, upon application of the active material in an uncontrolled manner, or absent exposure of the combined structure (i.e., the flexible base material plus the active material) to a trigger that activates the active material. In other words, a shape that is not a predetermined shape is not a manufactured or transformed shape. It should be understood that the term “predetermined” does not mean that every parameter, such as volume, angle, stiffness, etc., is known in advance, but rather that a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexible | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

| stretchable | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com