Safety Ring Support for Throwing Trap

a safety ring and support technology, applied in the direction of weapons, weapons, weapon components, etc., can solve the problems of high fabrication cost of the support arms, complicated dismount operation, increased processing cost and installation labor and time, etc., to facilitate storage of the safety ring support, facilitate mounting and dismounting, and save machining cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

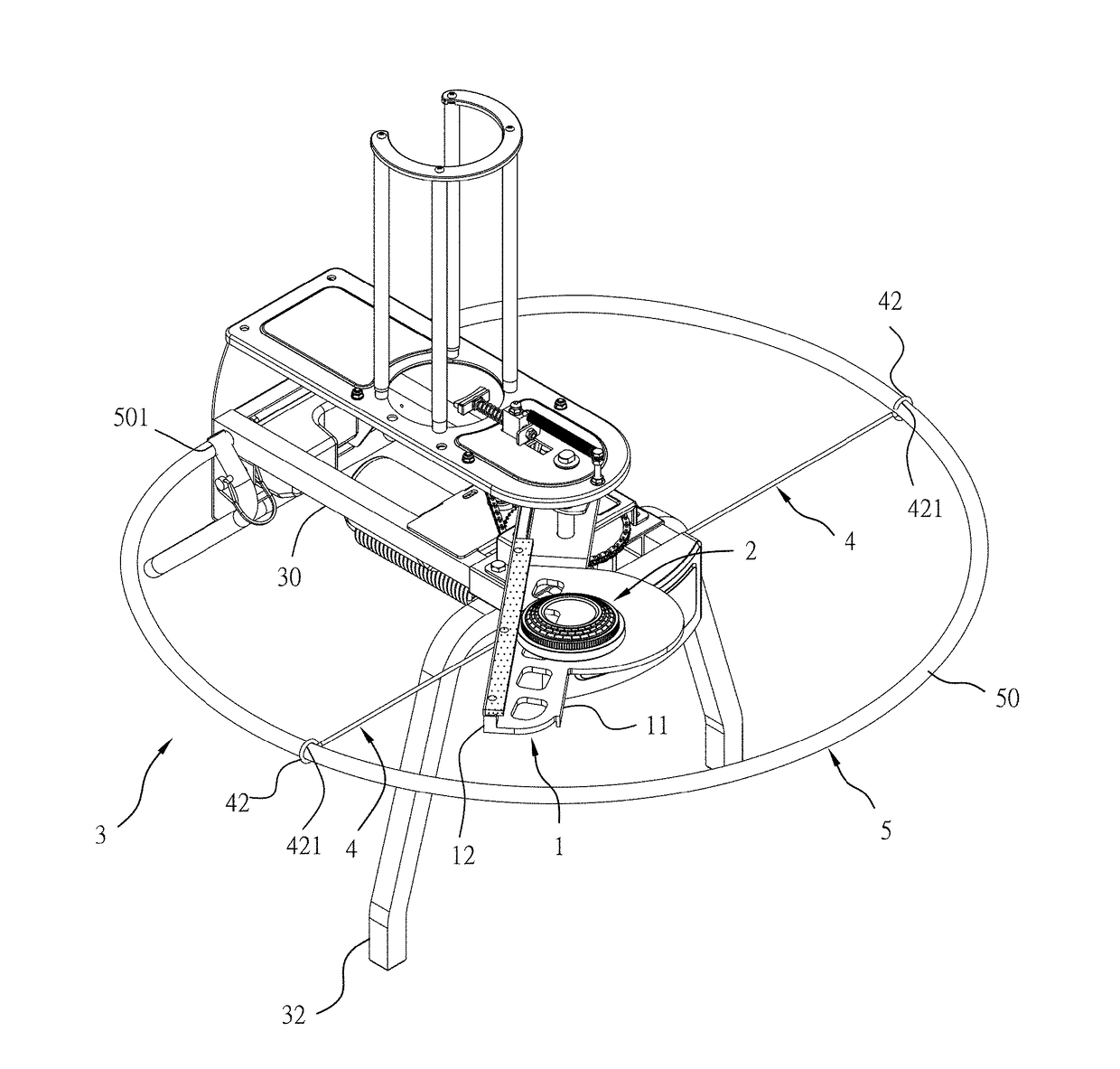

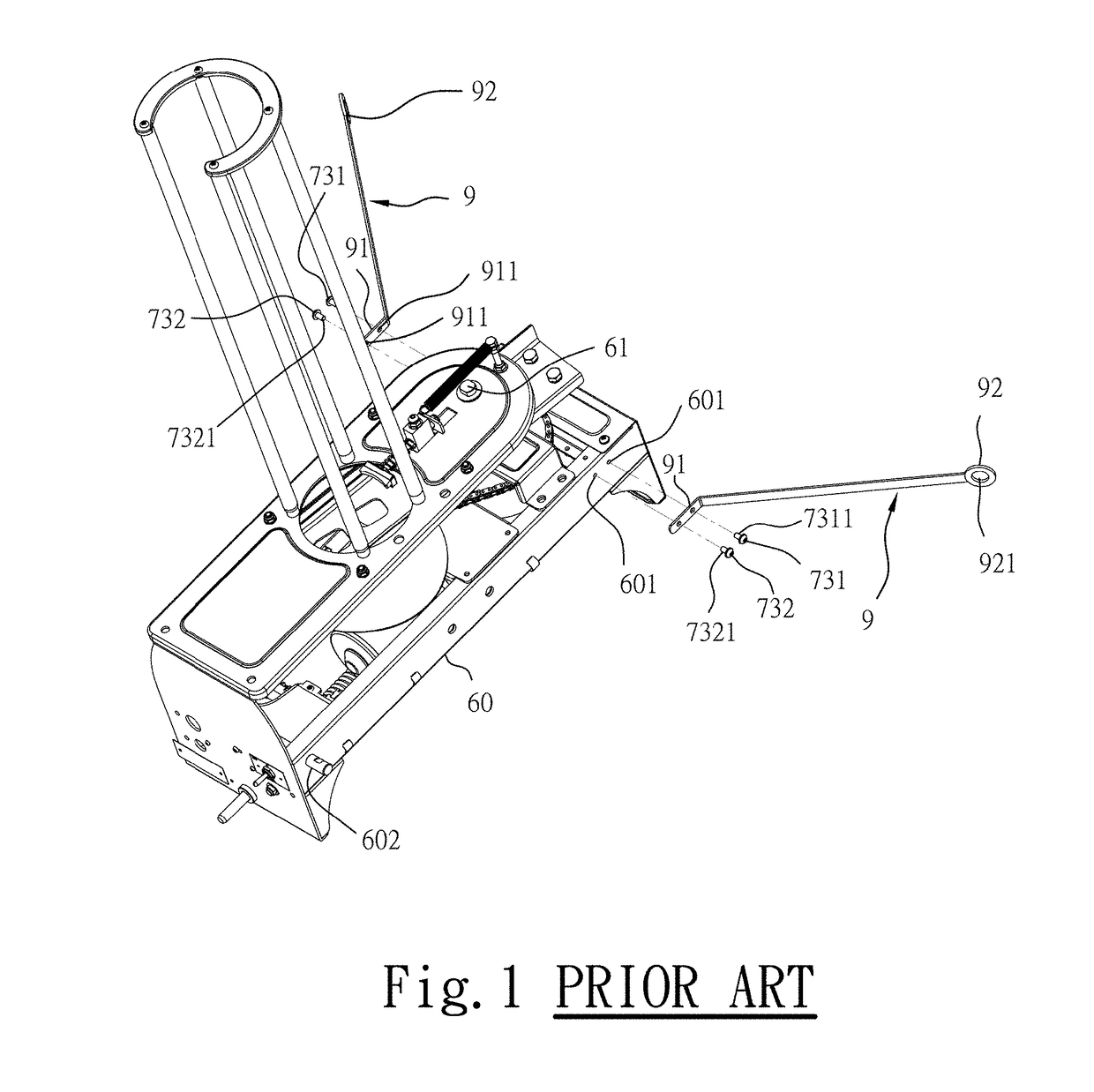

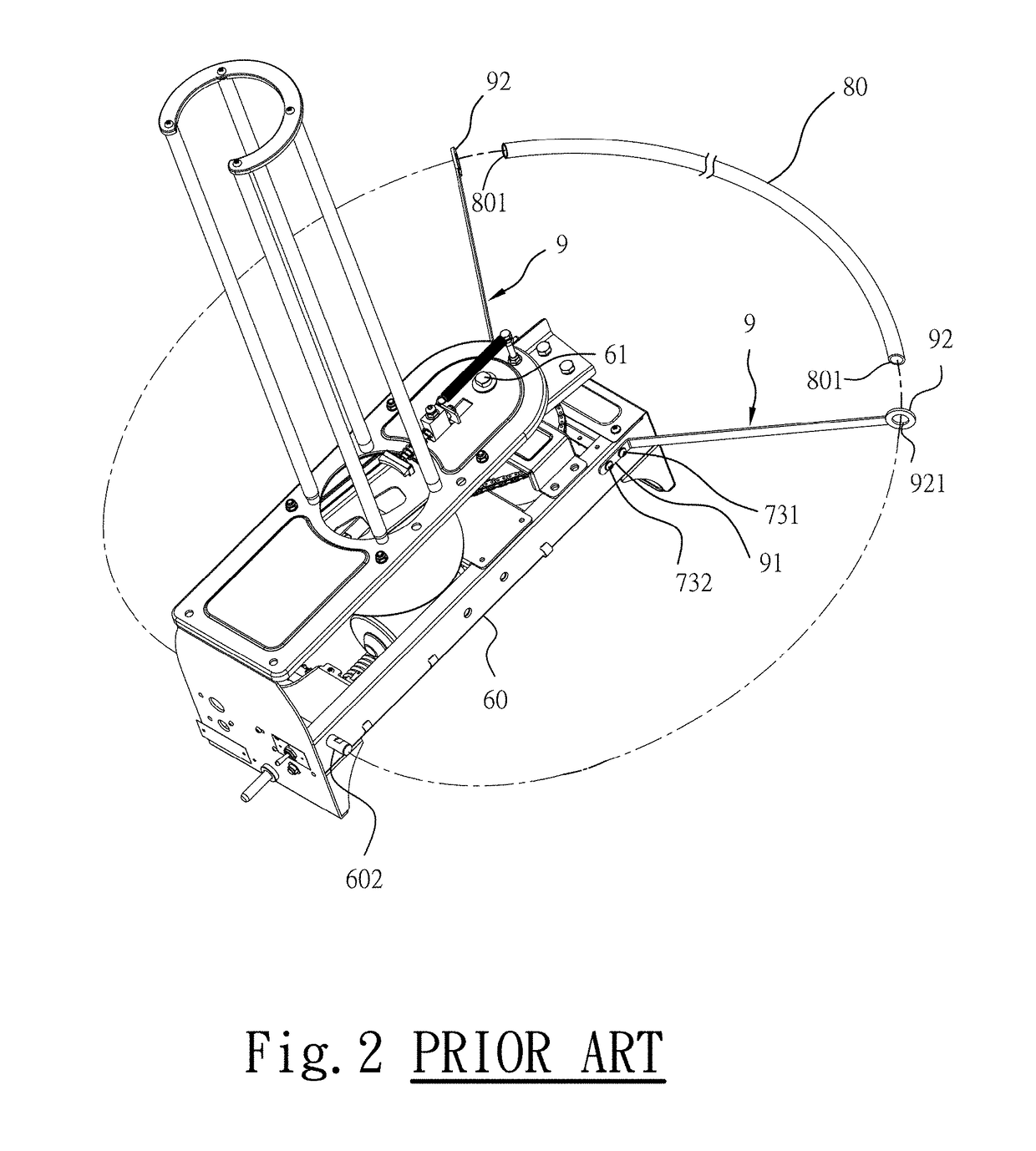

[0020]Referring to FIGS. 4-7, a safety ring support in accordance with the present invention is shown used in a throwing trap 3. The throwing trap 3 (see FIG. 7) comprises a throwing trap main unit 30 (see FIGS. 4-7) adapted for driving a throwing arm 1 to swing and to throw a clay 2 out of the holding target plate 11 thereof by means of centrifugal force subject to the operation of a push force plate 12 so that the user can aim at the flying clay 2 to perform a shooting training. Further, as illustrated in FIG. 7, the throwing trap 3 further comprises a front support 32. The safety ring support comprises two support arms 4 and a flexible tube member 50. The support arms 4 have respective one ends 41 thereof (see FIG. 4) respectively fastened to respective screw holes 301 at two opposite lateral sides of the throwing trap main unit 30 of the throwing trap 3 (see FIG. 4) near a front end of the throwing trap main unit 30, and respective opposite ends thereof respectively terminating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com