System for maintaining desired heated or cooled beverage for extended duration

a beverage can and long-lasting technology, applied in the field of thin-walled metal beverage cans, to achieve the effect of facilitating rapid heating of contents and thin volume of containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

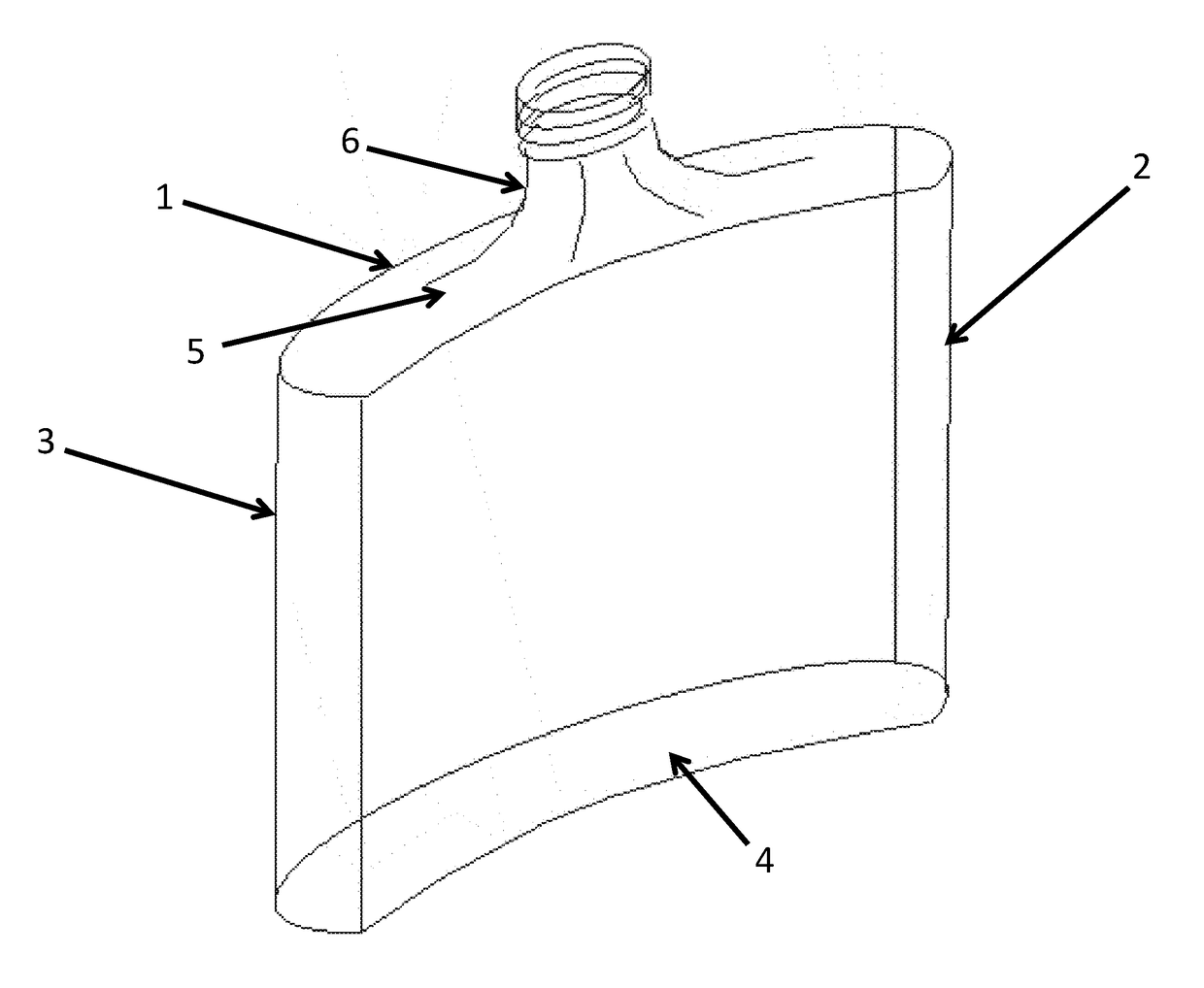

[0020]Referring in general to FIG. 1 there is shown a concave-shaped container (1) for use in the present invention which includes a container body having a front sidewall (2), a rear sidewall (3), a bottom wall (4), a top shoulder portion (5) and a neck portion (6). The material used to form the container body, when constructed from metal, is preferably an aluminum alloy in the 3000 series having an initial thickness of about 0.006-0.020 inch. Alternatively the container is glass of typical beverage container thickness, or high-temperature plastic.

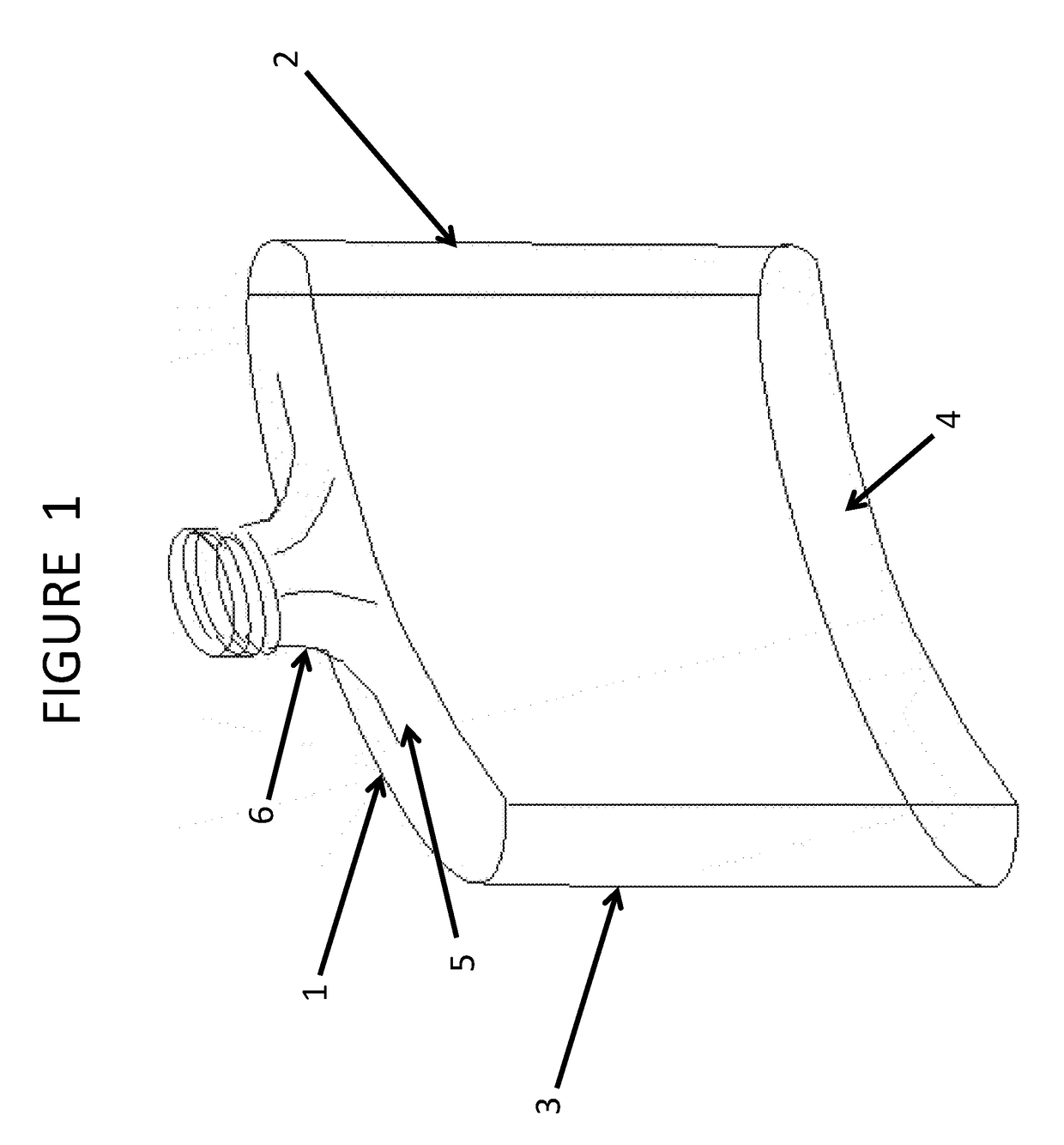

[0021]FIG. 2 shows a horizontal cross section of the container body (view from the bottom of the container) and the concave shape of the container (10).

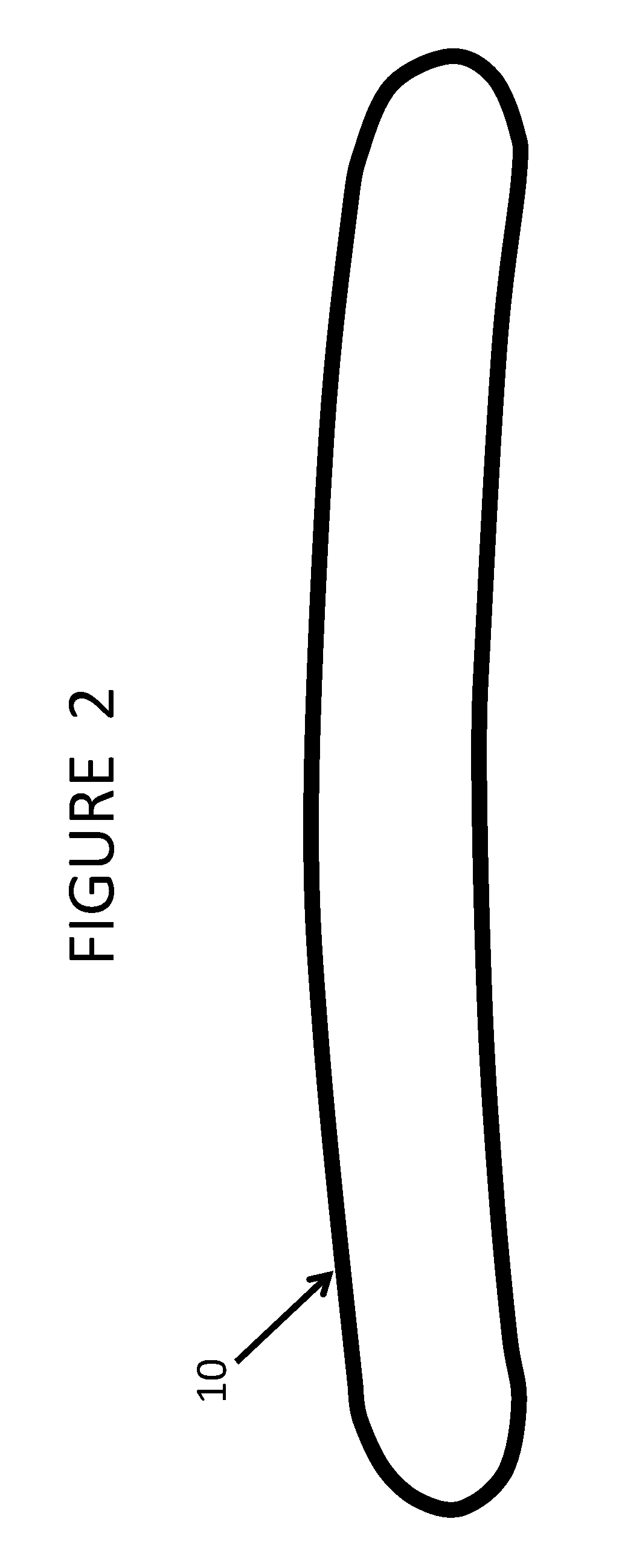

[0022]FIG. 3 depicts a horizontal cross-section of the thermal sleeve (11), which is comprised of paper construction with exterior smooth surface (12), corrugated middle surface (13) and smooth inner surface (14). The inner layer of the sleeve also contains a heat-reflecting barrier (15). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com