Heat exchanger with enhanced heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

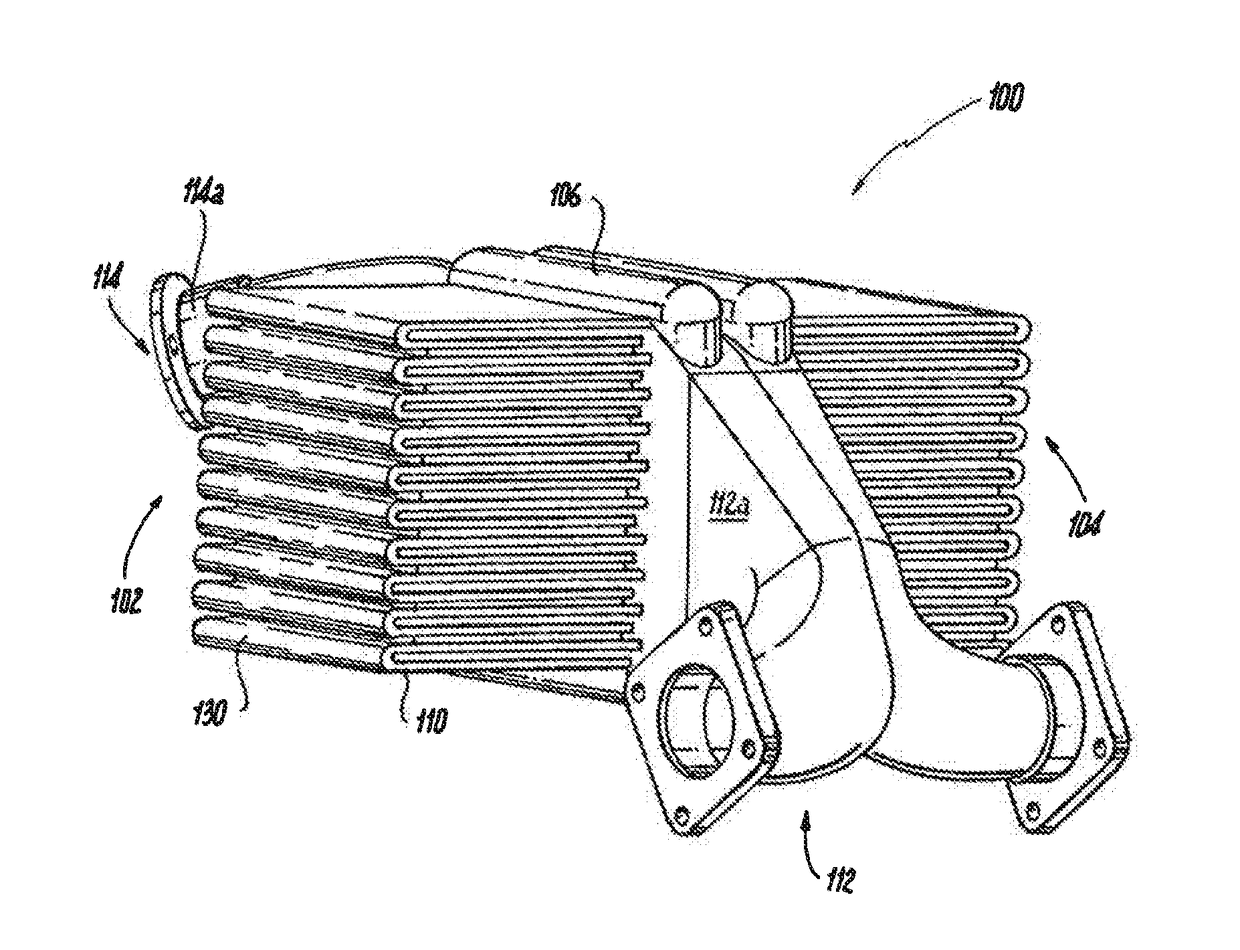

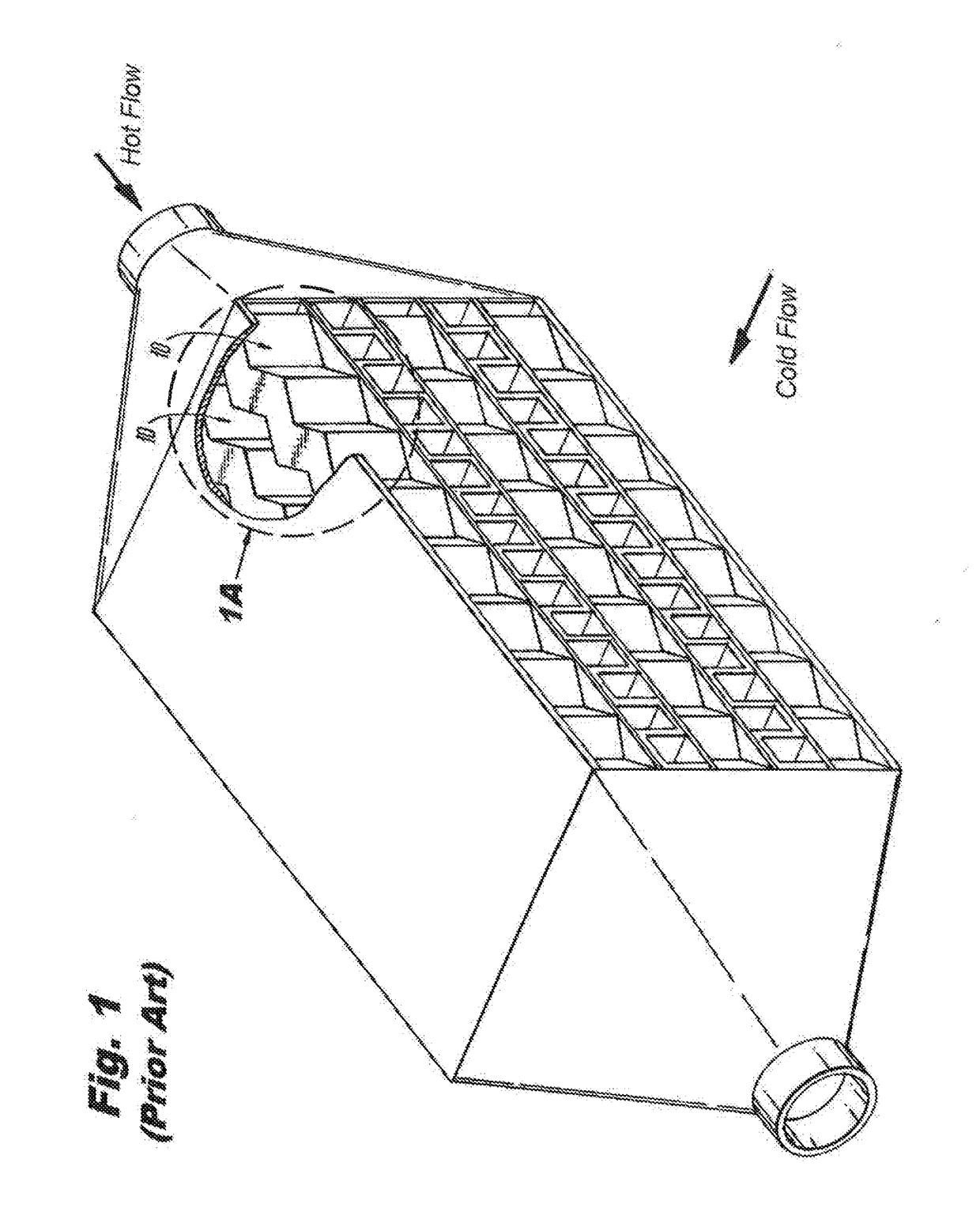

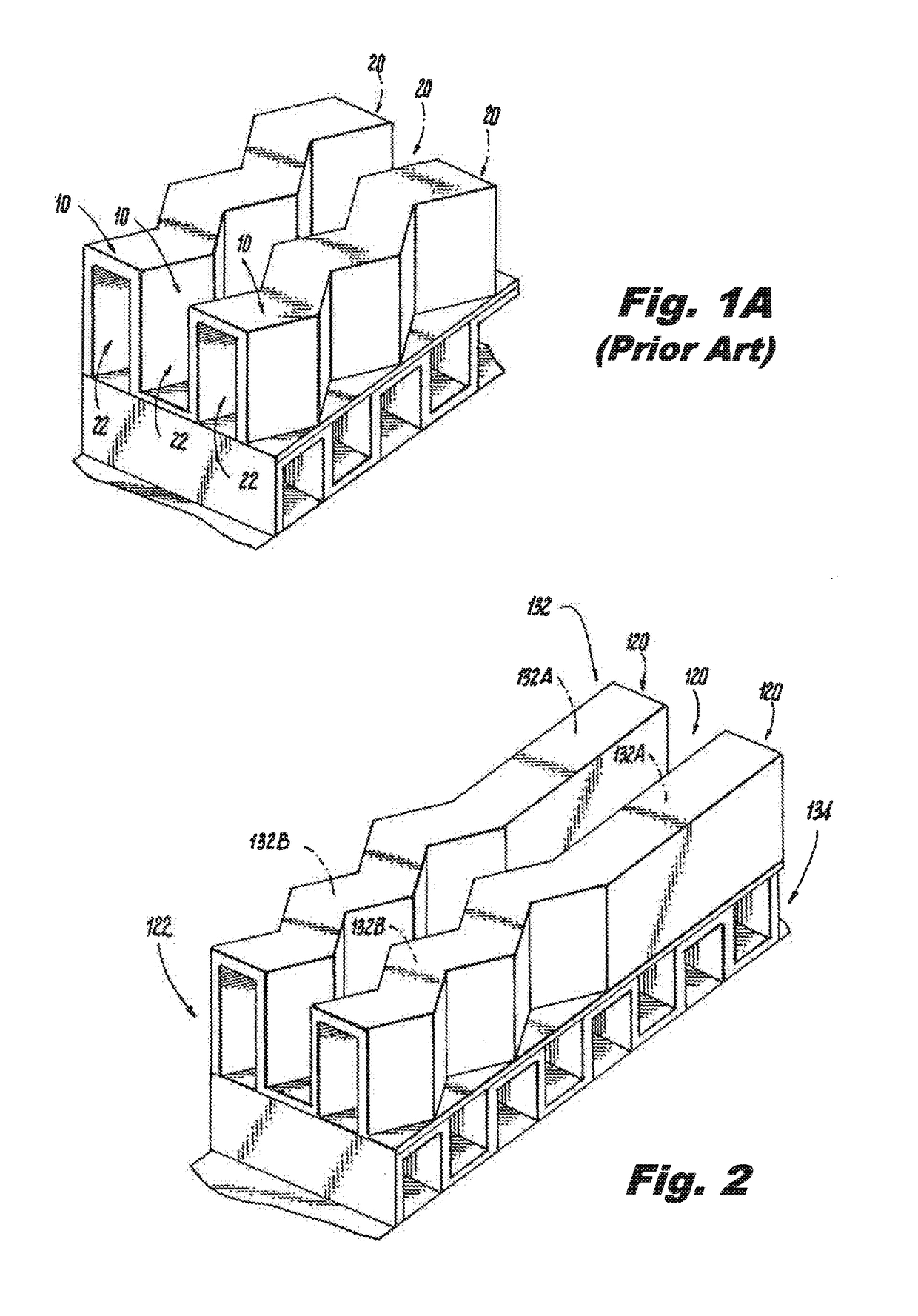

[0019]Reference will now be made to the drawings wherein like reference numerals identify similar structural features or aspects of the subject disclosure. For purposes of explanation and illustration, and not limitation, a partial view of an exemplary embodiment of a heat exchange device in accordance with the disclosure is shown in FIG. 2 and is designated generally by reference character 100. Other embodiments of the heat exchange device in accordance with the disclosure, or aspects thereof, are provided in FIGS. 1-3, as will be described. The systems and methods described herein can be used in turbine engines exposed to high pressure and high temperatures, for example in aerospace application. The present disclosure provides for a device that reduces the product of heat transfer coefficient and heat transfer surface area in regions of the device where metal temperatures must be limited to meet life requirements, while still maintaining a large product of heat transfer coefficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com