Weaving multilayer products using multiple warp columns and heddle columns

a multi-layer product and warp column technology, applied in weaving, looms, textiles and papermaking, etc., can solve the problems of poor warp control, difficulty in weaving, and too much warp and weft fiber congestion to weave efficiently, so as to reduce warp and weft fiber congestion and improve warp control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]Exemplary embodiments of weaving apparatus with warp columns counts and heddle columns counts are disclosed that facilitate weaving multilayer preforms where the ratio of warp columns to heddle columns is a fractional number and where a portion of the warp fibers are laceable through the heddles on one or more of the heddle columns based on the fractional number, allowing for better and more adequate shed space and efficient weaving than in prior art techniques.

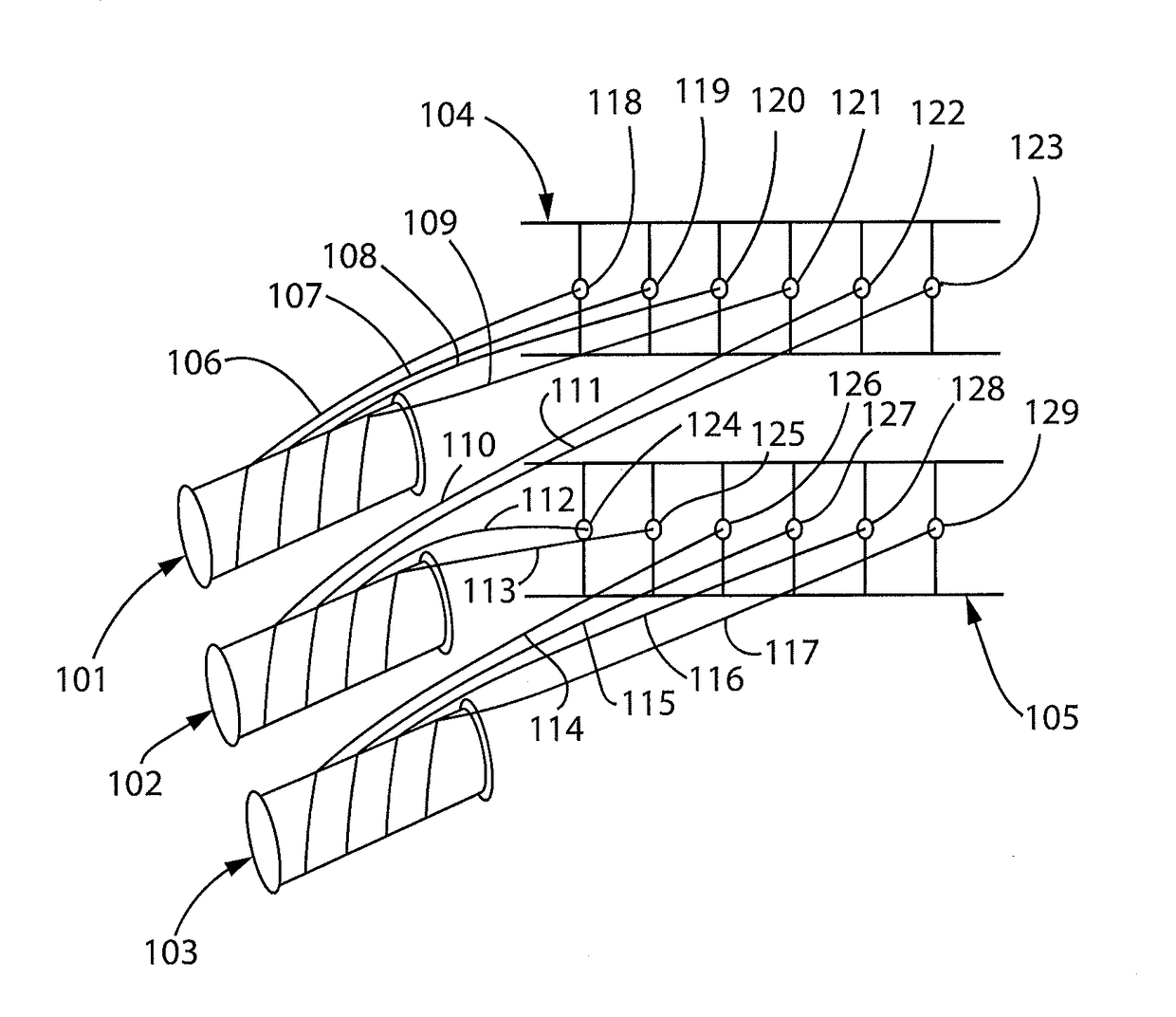

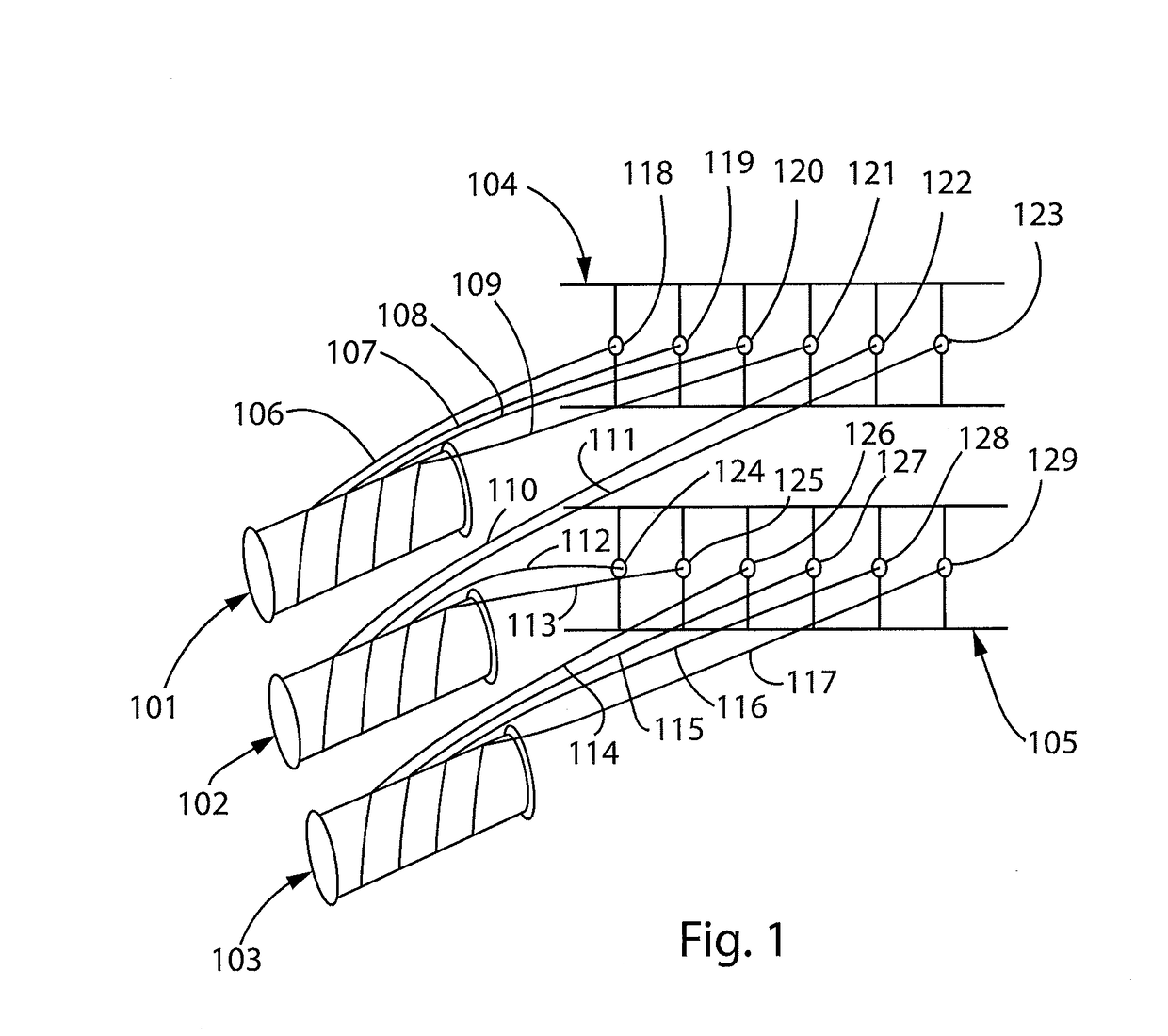

[0030]Turning to FIG. 1, it shows an exemplary weaving apparatus for weaving a 4-layer multilayer preform with two heddle columns 104, 105 and three warp columns 101, 102, 103. The ratio of warp columns to heddle columns is one and a half as determined by dividing the number of warp columns by the number of heddle columns. FIG. 1 shows warp fibers being laced through heddles on the heddle columns. Warp column 101 shows four exemplary warp fibers 106, 107, 108, 109. Warp column 102 shows four exemplary warp fibers 110, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com