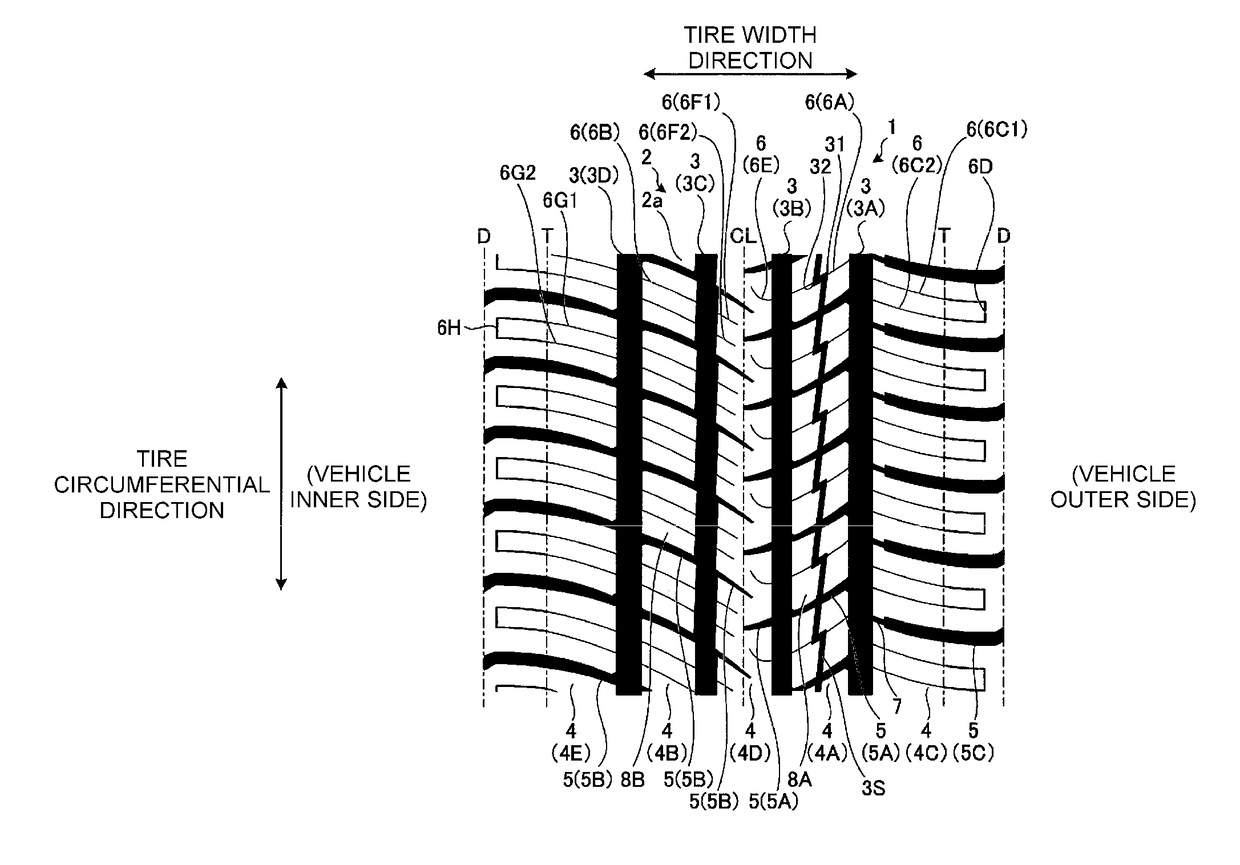

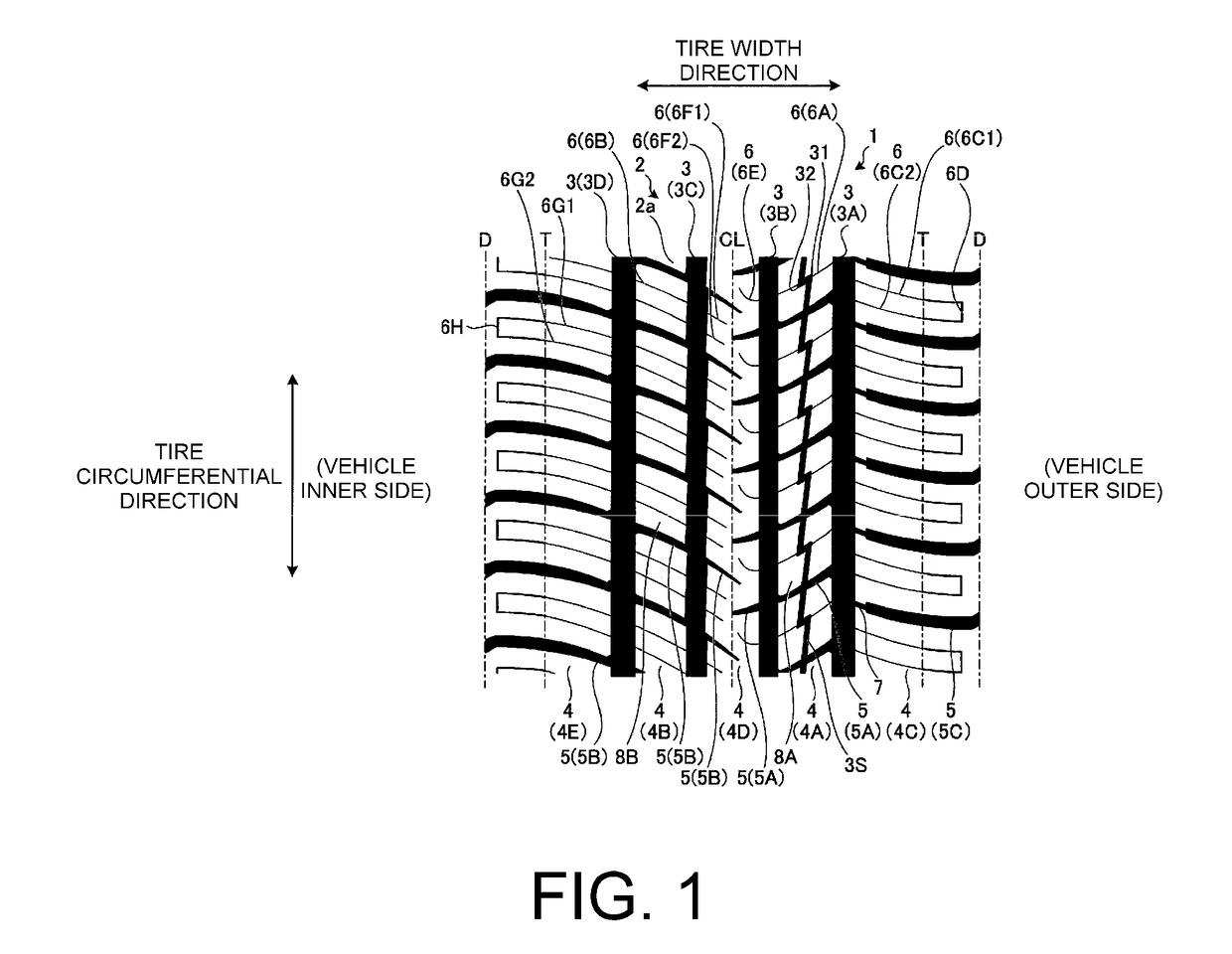

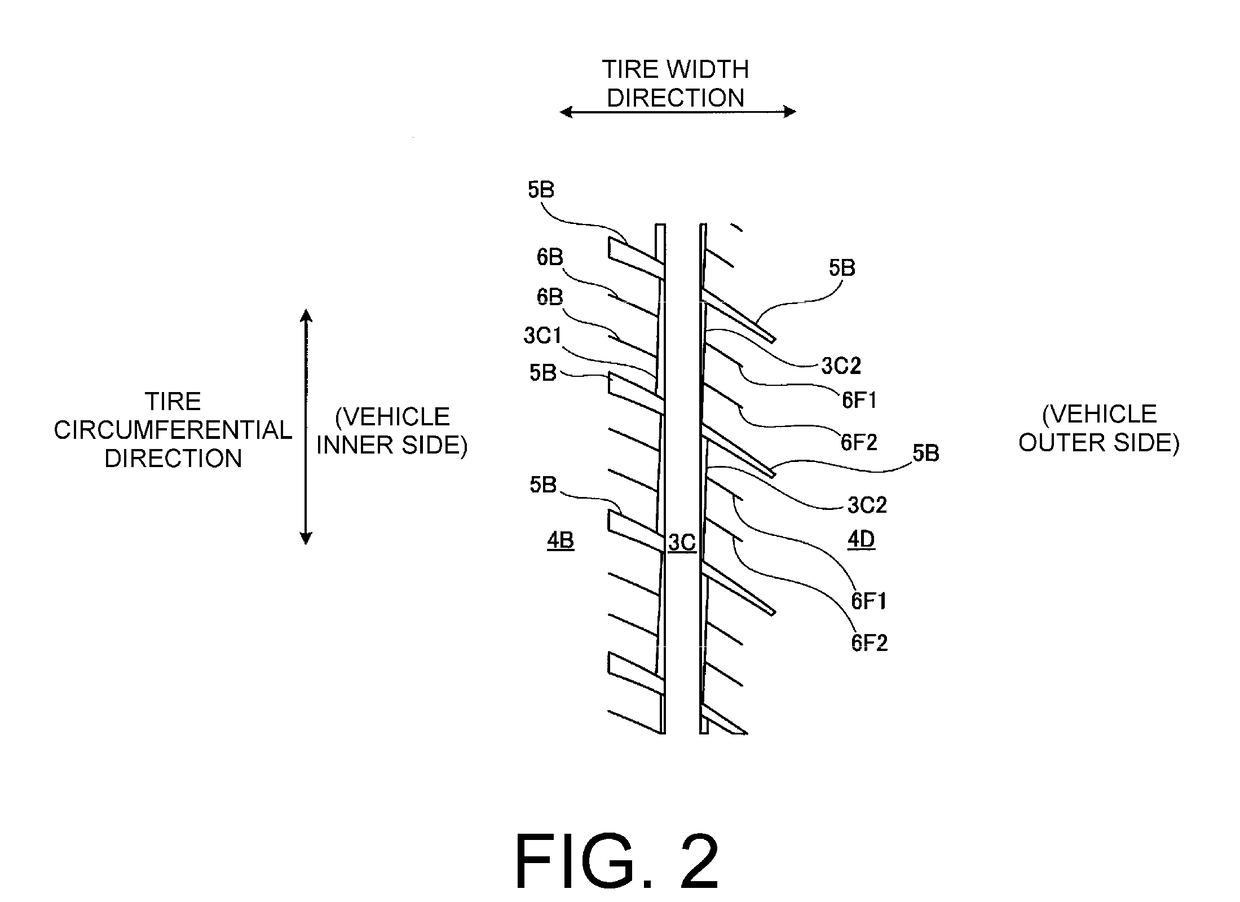

Pneumatic Tire

a technology of pneumatic tires and tires, applied in the direction of tyre tread bands/patterns, vehicle components, transportation and packaging, etc., can solve the problems of insufficient driving performance on snow-covered road surfaces when traveling straight and cornering, and insufficient driving performance on snow-covered road surfaces. the effect of improving the performance of dry road surfaces, wet road surfaces, and snow-covered road surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

working examples

[0176]In the examples, performance tests for braking performance on wet road surfaces, braking performance on snow-covered road surfaces, and braking performance on dry road surfaces were performed on a plurality of types of pneumatic tires of different specifications.

[0177]In these performance tests, a pneumatic tire having a tire size of 205 / 55R16 91V was assembled on a 16×6.5 JJ regular rim, inflated to the regular internal pressure (200 kPa), and mounted on a test vehicle (1600 cc front-engine front-wheel-drive vehicle).

[0178]The braking performance on wet road surfaces was evaluated by measuring braking distance of the test vehicle from a speed of 100 km / h on a wet road surface test course covered in 1 mm of water. Then, index values based on the measured results were assigned, with the result of Conventional Example 1 being defined as the reference (100). In this evaluation, larger numerical values are preferable.

[0179]The braking performance on snow-covered road surfaces was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com